For household electrical appliances, the socket is the power source. Behind its plastic front panel, there is a base with contacts for connecting a plug. Properly selected and installed devices work for a long time, but malfunctions can occur in any scheme. If the outlet is cracking and the noise is accompanied by arcing, you need to turn off the switchboard circuit breaker and find the cause of the malfunction.

Causes of sparks in the outlet

The purpose of the socket outlet is to connect the plug to the mains. During normal operation, current flows through the contacts with minimal heat generation. In some cases, a breakdown occurs when the plug is inserted into the outlet. The higher the power of the device being switched on, the more intense the sparking and crackling. The arc temperature is very high and the characteristic smell of molten plastic appears.

Sockets crack for several reasons:

- Exceeding the power for which the wiring product is designed.

- Long service life and natural wear of connectors.

- Loose contact clamps.

- The parts of the plug connection are manufactured according to different standards.

- The product is of poor quality with a short service life.

If, when turning on electrical appliances, the outlet short-circuits, temporarily use another power point. There are several factors that lead to breakage.

Overload

Wiring structures are designed for a certain rated current. The parameter is indicated by the manufacturer on the panel. Before the advent of powerful household appliances, it was enough to install a product with a current of 6-10 A, now the indicator is 16 A. For three-phase networks, the parameter is at least 32 A. Exceeding the rated current leads to heating of metal parts. The high power of the equipment increases the load on the wiring. For safety reasons, it is made from a cable with copper conductors.

The formula P = IxU will help to calculate the permissible power, where P is the power, I is the current, U is the voltage. For example: P = 10 × 220 = 2200 (W). The socket with a rated current of 10 A will withstand the connection of devices with a total power of up to 2.2 kW.

Overloading leads to burning of contacts. The remaining plaque reduces the conductivity and the resistance increases. Heat generation increases in proportion to these factors. The outlet can burn out, and with it the equipment.

Worn out connectors

The terminals have a high load. They are designed for a specific resource. After several years of operation, if the plug is inserted and pulled out frequently, the contact plates will unclench. They do not fit snugly around the pins. Intermittent contact causes crackling and sparks. The socket begins to warm up and hiss when the metal is covered with a layer of oxide. The process arises from moisture. Oxidized metal decreases spring properties. To extend the life of the device, it is worth turning off the devices with a special button, and not by pulling out the plug.

Loosening the screw terminals

If you hear a cracking sound in the socket, the screw connections may be loose. The situation arises from the heating and deformation of the metal.The process takes place in all wiring accessories, therefore, experts recommend carrying out preventive tightening of contacts once every 2 years. Aluminum wires are checked more frequently. When pulling up, it is important not to pinch the core, otherwise it will deform. One of the mistakes unskilled installers make is using a long screw. The fastener rests against the wall and does not allow the contact to be tightened properly.

During installation, it is advisable to wrap the wire in a loop around the screw. This method significantly increases the contact area. Modern devices are manufactured using screwless technology. Their installation is simplified and preventive maintenance is not required.

Inconsistency of the selected parts of the plug connector

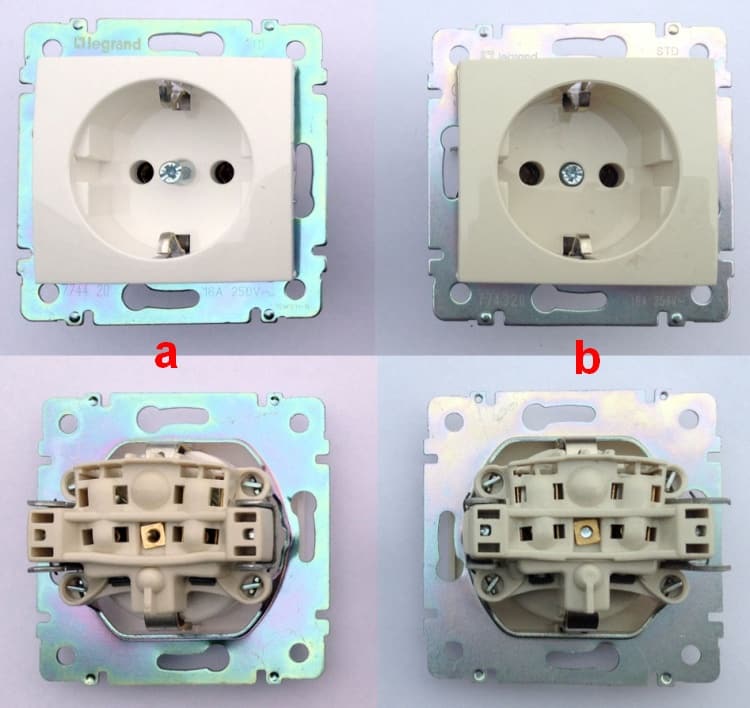

Plugs and sockets are manufactured in standard sizes. In Russia, two designs are used:

- European Type C or Europlug is a plug with two parallel round prongs. The distance between them is 19 mm, the diameter is 4 mm.

- Type F or Schuco - shockproof plug, grounding. It is widely used in Europe, popular in Russia and the CIS countries. The pins of the plug have a diameter of 4.8 mm.

The European plug is quite suitable for old sockets in size, and the F type is slightly larger than the design parameters. Plugging a large plug multiple times causes the contact plates to expand. When inserting the Euro plug, the crimp will be weak.

Also, from poor contact with plug C, the socket designed for type F plugs sparks. Connection is permissible for low-power devices, but with high power consumption, overheating occurs.

Poor device quality

Inexpensive wiring accessories quickly deteriorate. They use thin plates, unreliable fastening, contacts are loosely tightened. Chinese products are of low cost due to their poor quality. It does not correspond to the declared power, it loosens quickly during operation. Due to the high load, the sockets hiss and fail after a maximum of 2 years.

High-quality products of the budget segment - goods from Vico, Makel. European brands Legrand, ABB have inexpensive series.

How to fix a breakdown

If the sockets spark, you need to call an electrician or try to fix the damage yourself. First of all, turn off the power on the dashboard and warn the tenants of the apartment about the repair. To inspect the contact part, you will need to remove the front panel. Procedure:

- Check the condition of the wires, oxidation on copper must be cleaned with sandpaper.

- Tighten the screw clamps with a screwdriver, bend the contact plates.

- Inspect the wiring, if there are exposed areas, cover them with insulating tape.

- Fasten the structure with set screws located on the sides.

You can check the quality of the repaired structure by inserting a plug. Tight crimping of the pins indicates the elimination of basic problems. When the electricity supply resumes, the point is checked by turning on a medium power appliance such as an iron. If the result is satisfactory, it is recommended to periodically observe the condition of the plug connector.

If the contacts and plastic are blackened and charred, it is best to replace the outlet. In case of non-compliance with the standards, you will have to buy a modern wiring product of a suitable type. It will ensure the normal use of household appliance plugs.

It is impossible to increase the power of the outlet, therefore, to connect electric boilers and stoves, a structure with a rated current of at least 16 A is installed. If the power of one point is not enough, several should be installed. The socket strip is safer than a tee.

Consequences of sparking in the socket

in the outlet, sparks and melting of the structure can lead to a short circuit.In the most unfavorable combination of circumstances, it causes a fire. Bad contact will knock out the machine, melt the insulation of the electrical wiring. A voltage drop leads to damage to household appliances, laptops and computers. A faulty electrical installation is dangerous to human health.

In the manufacture of outlets, manufacturers lay a margin of safety. This applies to original products. Counterfeits or goods of unknown origin can break down in a short time. After the first sparks, crackles or hums are noticed, a good socket does not need to be replaced. You need to check its condition and troubleshoot.