Previously, overhead transmission lines used exclusively unprotected conductors without an insulating layer. They were less reliable, had a short service life and could lead to a short circuit in the event of a line breakdown, but in general they coped with their work. Now there is a transition to more reliable insulated conductors. Such products include a self-supporting insulated wire cable. It is presented in various forms, each of which has its own characteristics, advantages and disadvantages. It can be used both outdoors and inside houses to create electrical wiring.

Varieties of self-supporting insulated wire

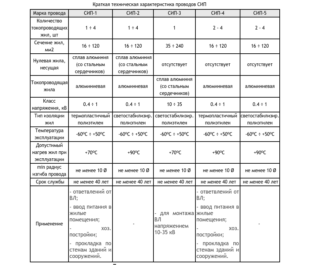

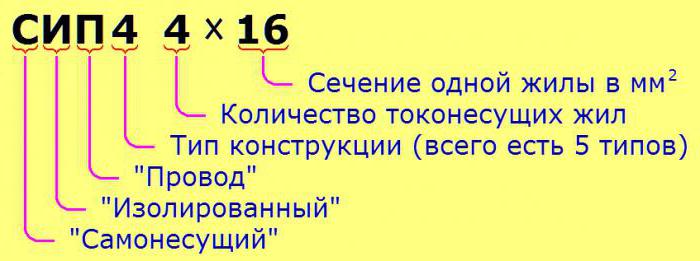

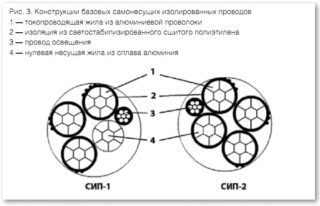

SIP wire can be divided into several different categories depending on the material from which it is made and the design. Differences include conductor diameter, number of cores, insulation material. All types of SIP cables must have an insulating layer. Explanation of the name: C - self-supporting, I - insulated, P - wire.

SIP-1

SIP-2

They are also divided into SIP-2 and SIP-2A. Able to withstand temperatures up to 90 ° C. The minimum bend radius is 10 diameters.

SIP-3

This modification has significant differences from the previous two types. It consists of a steel core with a braid of aluminum, silicon and magnesium. PET is used as insulation material. Single-core. Suitable for conditions up to 20 kV. Suitable for work in any climate except arctic and continental. Operating temperature range from -20 ° С to + 90 ° С.

SIP-4

The conductor is created from several pairs of cores without a neutral wire. The label has the letter H, indicating that an alloy is used as the material for the conductors. In the absence of a sign, it can be judged that the conductors are made of pure aluminum. Insulation - thermoplastic PVC, which protects the wire from ultraviolet rays.

SIP-5

It is similar in design to SIP-4, but PET is used as the insulation material. Thanks to this, it is possible to increase the maximum permissible temperature by 30%, which expands the climatic zone of application. It is used in power lines with voltages up to 2.5 kilovolts and connections to various buildings, street lighting, branches to cottages. Recommended for use in regions of cold and temperate climatic zones.

Conductor marking

SIP cables can be designated with a classic alphanumeric code and color of the insulating layer. An example of decoding will be considered based on SIP-1 - 3x50 + 1x70 - 0.6 / TU 16-705.500 - 2007

The first letters show that the SIP-1 modification without an insulated zero core is used. There are 3 phase conductors with a cross section of 50 sq. Mm. and one zero conductor with a cross section of 70 sq. mm.Further, the operating voltage is indicated, which is 0.6-1 kV. Then the number of technical conditions, in accordance with which it is executed, and the year of issue (2007) are written. There should also be a manufacturer's label with the name of the plant.

Labeling rules:

- Phase veins are marked with numbers, stripes by inscription or embossing.

- Zero is not indicated.

- Color coding in the form of a strip with a width of 1 mm or more can be used instead of an alphanumeric code or at the ends of the wire.

- For lighting, auxiliary conductors are used, which are marked as B1, B2, B3.

- According to the requirements of GOST, all designations must be applied along the entire length at a distance of 50 cm from each other.

- Standard sizes of signs are more than 2 mm wide, 5 mm high.

- Auxiliary conductors may not have a designation.

- The quality of the marking must be of a high level, it must not be erased, it must not react to ultraviolet rays and change during the entire period of operation.

By marking it is possible to understand which conductor is used, what properties and operating conditions it has. Such information is also duplicated in the conductor's passport.

Cable properties

SIP cable is also suitable for creating street lighting. The best option is a product with cores of 25 sq. Mm.

The main parameters of the conductor according to the GOST standard:

- Maximum permissible load. Directly depends on the cross-sectional area. Defined in kW.

- Operating temperature limits.

- Humidity, water and UV resistance.

- Temperature limit at critical mode.

- Bend radius.

- Warranty (usually 3 years).

- Lifetime. If the requirements are met, it is 40 years or more.

There may be differences depending on the cable manufacturer. But they must be within the limits established by GOST.

By the name SIP is a wire, but by its characteristics it is a cable.

SIP cable fittings

Wire installation requires the purchase of additional accessories. They allow you to fix the product on the surface, lengthen it as needed. All parts must be selected specifically for the selected cable in order to do their job efficiently.

For a self-supporting insulated wire wire, the following equipment is needed:

- Piercing clamps. They allow you to make the connection of conductors in such a way that it is not required to remove the insulation from the cable.

- Branching parts.

- Anchor fasteners. Helps to secure the clamps.

A bandage tape is also used. All necessary components must be resistant to rust formation, ultraviolet radiation and temperature fluctuations.

Installation features

The self-supporting insulated wire is a reason that is used mainly for conducting electrical lines in the open air. The connection is carried out on a centralized line.

For self-connecting and conducting the cable, you need to obtain permission from the relevant organizations that are engaged in power supply. Without fail, a project plan is developed indicating the conductors used. You will need professional equipment to work.

Wire insertion is carried out using piercing clamps. After that, you need to connect the tips. Suspension is carried out using ropes that are pulled between the posts (for lengths over 25 meters). Holders are made to install the cable on the poles.

If you need to stretch the cable along the facade of the building, use anchors. Their number should correspond to the number of lead wires. The cable can be inserted into the house no more than 1 meter, after which it is wired inside the building.With non-combustible material at home, the cable on the wall is laid in an open way. This can be done in a corrugated pipe or plastic box.

For air laying, the SIP brand is used 2x16, 4x16. The first is also used for branching lines in the room and connecting to machines and meters.

Advantages and disadvantages

The positive aspects include:

- No need to install powerful insulators.

- Good current characteristics.

- Safety for the service technician.

- Small line track width.

- High ultimate power.

- Long service life.

- Efficiency in all weather conditions.

- Resistant to corrosion.

- The absence of harmful components in the composition, which guarantees environmental safety for humans and animals.

- Overlapping the cables does not affect performance.

- Easy to stack, easy to connect.

Cons of the electric cable:

- Large weight of 1 meter. Frequent installation of supports is required.

- Improved insulation required for industrial use.

Despite its shortcomings, the cable is actively used for laying power lines. The calculation of the required length and cross-section depends on the connected load.