To understand what an LED is, you first need to understand its generally accepted designation, represented in English as LED. Translated, this literally means "emitting small LEDs". From a technical point of view, they are semiconductor devices that convert electric current into visible light. This simplest product in its appearance and design differs markedly from typical lighting devices: incandescent lamps and the like.

History of origin

The device and the principle of operation of LED emitters is easier to understand if you familiarize yourself with the background of their occurrence. For the first time this emitting product was born in 1962 in the form of a monochrome red diode. Despite a number of shortcomings, its manufacturing technology was recognized as promising. A decade after showing the red sample, green and yellow LEDs were introduced to the general public. Due to their low recoil, these products were mainly used within the home as indicators on the front panels of household electronic appliances.

Over time, the intensity of the glow was increased several times, and in the 90s of the last century it was possible to make a sample with a luminous flux equal to 1 lumen. In 1993, the Japanese engineer S. Nakamura created the first ever blue diode, characterized by an increased level of luminosity. From that moment on, their developers learned how to get any color in the visible spectrum, including white.

Thanks to the remarkable characteristics of LED products, over time they have become a serious competitor to the incandescent bulbs familiar to many.

Since 2005, the industry has mastered the production of white LEDs with a luminous flux of up to 100 lm and more. In addition, they learned how to make lighting elements with different shades of white ("warm", "cold" and other glow).

The device and principle of radiation formation

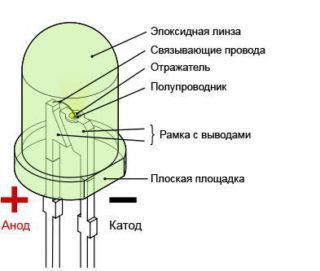

To understand how an LED works, first of all, you need to take into account a number of points regarding its design:

- the basis of the LED element is a semiconductor crystal that passes current only in one direction;

- the classic LED device assumes the presence of an insulating substrate;

- the glass body of the diode reliably protects the crystal from external influences and is at the same time a scattering element;

- there are two contacts on the back of the case, to which the LED is supplied with electrical power.

To increase the operating life of the emitting device, the space between the diffusing lens and the crystal itself is filled with a transparent silicone compound.

In the structure of some LEDs, a special aluminum substrate is provided, which is the base of the device and at the same time removes excess heat from it.

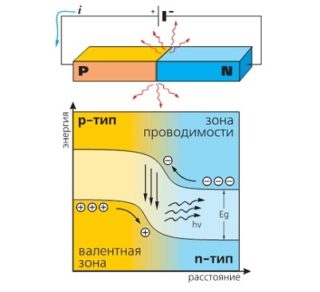

It is easier to understand how an LED works by examining a semiconductor junction, which professionals call an electron-hole junction. Its name is associated with the different nature of the main carriers in the boundary layer of the two structures. In one semiconductor, there is an excess of electrons at the contact boundary, and in the adjacent material there are excess holes.In the process of manufacturing a semiconductor junction, they penetrate into the adjacent layer, forming a potential barrier that prevents their reverse bias. The value of the forward voltage on the LED during its operation depends on the width of the junction.

When a potential of a given polarity and a value generated by a constant current source is applied to the diode, it is possible to displace the junction in the desired direction. This will lead to its opening and the appearance of a counter flow of oppositely charged particles. When they collide, quanta of light energy - photons - are emitted within the boundaries of the transition. Depending on the repetition rate of these pulses, the radiation acquires a certain color coloration.

What determines the color of the LED

In the manufacture of LEDs, various types of semiconductor materials are used, the choice of which determines the color shade they emit.

The ability to distinguish color is an innate property of the human eye, capable of capturing its gradations with great accuracy. It is inextricably linked to the wavelength of quantum radiation that electromagnetic waves of a certain frequency carry with them. In this case, light pulses are formed at the semiconductor junction border of the LED.

When studying the properties of various semiconductors at an early stage of their study, scientists have identified materials such as gallium phosphide, as well as ternary compounds AlGaAs and GaAsP. When using them, it was possible to obtain red and yellow-green radiation. Today, in order to obtain various color combinations, more complex combinations of aluminum with indium and gallium (AllnGaP) or indium-gallium nitride (InGaN) are used. These semiconductors are capable of withstanding significant currents, which makes it possible to obtain high luminous efficacy from them.

Color mixing technique

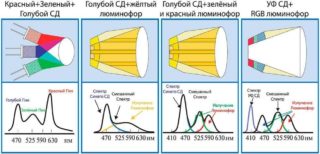

Modern diode strips and LED modular clusters are capable of producing various shades of the light range. Given that one transition generates monochrome radiation, a multi-chip device is required to create a multi-color glow. This complex product works like a computer monitor, on which it is possible to obtain almost any shade (for this, a special RGB module is used).

Taking advantage of this principle of shading formation, it was possible to obtain a white glow, which is widely used in LED floodlights, for example. To do this, all three original or base colors were mixed in equal proportions.

It can also be obtained by combining diode structures of ultraviolet or blue radiation with a yellow phosphor-type coating.

Features of LED manufacturing

To understand how LEDs are made, you need to familiarize yourself with the features of the structure in terms of the technologies used in the manufacture. Therefore, when considering the specifics of their production, first of all, the following points are taken into account:

- a specific method of forming the color of the radiation (matrix or phosphor);

- how many volts LEDs are designed for, and what current value they withstand;

- which technology allows you to get the best quality of the glow and is cheaper.

Manufacturing chips using a matrix scheme will cost the manufacturer more, which pays off with the high quality of radiation. The disadvantages of phosphors include low light output, as well as not entirely pure color of the radiation. In addition, they have a shorter working life and are more likely to fail.

In the manufacture of simple indicator diodes with a direct voltage of 2-4 Volts, their transition is calculated for small currents (up to 50 mA). To create full-fledged lighting devices and LED bridge circuits, devices with high current rates (up to 1 Ampere) will be required. If in one module diodes are connected in a serial chain, the total voltage at their junctions reaches 12 or even 24 volts.During the manufacture of products, the plus for each LED is marked in a special way (a small protrusion is made on the corresponding leg).

Applications and glow control

Due to the variety of modifications, LED products are widely used in various fields:

- in the manufacture of energy-saving lamps installed in a typical chandelier, for example, or in an ordinary wall sconce;

- for use as illuminators in widespread miniature lanterns, as well as in larger structures such as "camping camping lamps";

- if necessary, decorative illumination of premises in the form of long ribbons with different colors.

Their use is due to the degree of resistance of the device to climatic factors, assessed by the protection class of the product. Depending on the design, they are used only indoors or they can work in open spaces (as a decoration for billboards or LED rain, in particular).

You can control the level of luminosity in an ordinary lamp or chandelier in various ways. For this, special electronic circuits are most often used, which allow modulating the amplitude and other parameters of light pulses. For the convenience of working with household equipment, such a module is manufactured in the form of a standard control panel.