An electrical outlet is an integral part of power supply networks in any premises. Points are installed in every building, apartment, summer house, street and other places. The modern market for electrical materials offers different options, sometimes fundamentally different models. Before buying, you need to familiarize yourself with the main types of devices, the advantages and disadvantages and how the socket is arranged.

- Electrical outlet device

- Contact materials

- Grounding contact

- Connecting wires

- Classification of electrical outlets

- Voltage and current

- By type of installation

- IP degree of protection

- Number of slots in one housing

- Power points with additional capabilities

- With power monitoring functions

- With increased ease of use

- Childproof

- Design features

- Types of electrical outlets in different countries

Electrical outlet device

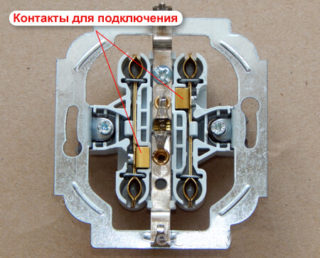

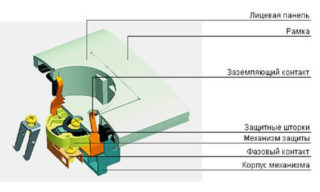

A classic electrical outlet is assembled from a plastic outer panel (the material may be different, the purpose is to cover the internal parts) and a non-conductive base with micro contacts and plugs. The latter are necessary to secure the plug of the devices.

The base is made of heat-resistant plastic or ceramics, the main thing is that the material does not conduct electricity and does not melt during short circuits, fires. Plastics are cheap and durable; ceramics cost much more and are significantly fragile. The number of contacts, the shape and size of the outlet depend on the type and purpose (for example, three-phase have six contacts, single-phase two), as well as the country of manufacture. During production, they are guided by the provisions of GOST or special specifications.

Contact materials

- bronze - suitable for all types of premises, different operating conditions;

- brass - used only at a normal level of humidity in the room, it is forbidden to install in saunas, bathrooms, on the street - they will quickly fail, a short circuit may occur, devices burn out;

- tinned brass (protected from corrosion) - perfectly tolerates high humidity, special processing will not allow moisture to affect the metal and destroy it.

Brass micro contacts are the most vulnerable. The metal is pale yellow, shiny. Under constant exposure to moisture, it oxidizes, rusts. The increased rigidity of the material does not allow the contacts to spring, which over time leads to a deterioration in the connection - under the pressure of the plugs, the plates diverge and cease to close the electrical circuit. Additionally, you have to install springy "petals" that bring the contacts together.

The processed - tinned - brass is very different from the original material. The color becomes white, matte. Thanks to the anti-corrosion coating, the contacts do not oxidize, they spring easily and retain their original bend. Therefore, the material is used in street sockets and installed in rooms with high humidity.

Bronze contacts are rare. You can find out a rosette with bronze elements at a price that is much higher than the classic models. The color is dark yellow, matte. The material is well resilient, keeps its original shape and provides a reliable connection for a long time.

Grounding contact

- high-power devices and equipment;

- devices "sensitive" to the quality of electricity (in particular, electronic);

- appliances that use water in their work (for example, washing machines and dishwashers).

In addition, grounding types of sockets are installed in rooms with high humidity and outdoors - a safety requirement when working with electrical devices and wiring. Working grounding in the outlet device will protect users and technicians.

Installing power points without grounding contacts is possible only in dry rooms and when connecting low-power devices: table lamps, charging, convectors, etc.

Prices for simple models are lower. The depth of planting into the wall is less, so a small hole must be drilled for them. However, such sockets are not suitable for powerful devices (including computers). The danger also lies in the accumulation of residual static electricity, which is detrimental to electronics.

Connecting wires

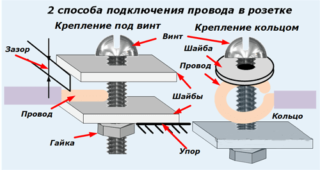

Screws are divided into two types:

- option with fixing the wire at the end in the form of a loop;

- method of direct fixing of the end of the cable.

The first method requires a long connection time: the screws are completely unscrewed, the wire is twisted in a loop (round-nose pliers can be used), then the loop is put on the bolt, the final look is formed, and fixed with a nut. The second - the connection is done quickly - the screw is loosened, the end of the cable is inserted into the resulting gap, tightened tightly.

During operation, contacts are constantly exposed to certain influences - heating, cooling, pressure. Over time, microcontacts weaken, may become unusable. Therefore, it is necessary every six months to check the condition of sockets of any kind and correct the connection: tighten the screws, tighten the plates.

Modern sockets are often installed in blocks - 3-4 pieces side by side and under one outer cover. Such a parallel connection provides for a wire connection of wires to each power point, the jumpers are carried out in separate connectors.

Classification of electrical outlets

The electrical outlet has a simple structure, but in recent years the number of models and classes of such devices has grown significantly. It is enough to get acquainted with the main types of the mechanism in order to choose the most suitable option.

Voltage and current

Technical characteristics are the most important indicators that should be considered when choosing. The required voltage and current are calculated. By the first value, sockets are distinguished:

- single-phase for 220-240 V - the standard version on the territory of the Russian Federation and some former Soviet republics;

- single-phase 100-127 V - USA, Japan;

- three-phase 380 V - more often installed in production.

In addition to the voltage, the nominal throughput is taken into account - the current strength that the device can pass for a long time. Standard sockets are designed for 10-16 A. For devices with increased power (household heaters, electric stoves, etc.), a value of 32 A and higher is required. Such power points are called power points: they differ in size, more heat-resistant materials, contact density, and price.

By type of installation

Electrical outlets can be installed in two different ways - inside the wall (other surface) and outside. The internal socket requires a special hole in the surface: the socket is channeled, cut out in the panels.After installation, such a device turns out to be almost invisible - as much as possible flush with the surface.

Surface mounted rosette suitable for surface mounting. Fastened directly to the wall on rails, no socket required. They are often used outdoors. The external power point is suitable for garages, technical premises, change houses - places where the aesthetic component of the interior is not the main thing.

Retractable sockets (usually quadruple) are a novelty in the market of electrical materials. They are convenient to use in the kitchen. It can be mounted in a worktop, to the bottom of a wall cabinet, to the side of furniture and can be opened as needed.

IP degree of protection

The latest models of single and multi-socket outlets have an additional option - IP protection. The technical characteristics indicate that the device is protected from moisture, dust, debris. It is necessary to pay attention to the indicator if the power point needs to be installed in a room with "extreme" conditions or on the street. The following meanings are often found:

- 20 - normal conditions of use, heating in winter;

- 21, 22 - tolerate low temperatures well (no additional heating is required);

- 43, 44 - rooms with high humidity, places near water;

- 54, 55 - the most protected, installation on the street is permissible.

These options meet the usual requirements for the construction of a house, summer residence. Finding devices with higher values is difficult and rarely necessary.

Number of slots in one housing

For convenience, several power points are built into one case. If two or more sockets are installed, the design is called a socket block. In addition, additional connection points are installed - the Internet, USB, television, and others. Standard options for sockets in blocks:

- single;

- double;

- triple.

In new buildings, blocks are made up of single food points, covered by a common panel. Socket boxes are made separately for each or one common.

Power points with additional capabilities

Sockets are installed everywhere - in separate toilets on the street, garages, factories, offices and residential premises. Therefore, manufacturers are constantly trying to improve devices, make design changes and add interesting details.

With power monitoring functions

When repairing a capital level or laying new electrical wiring, they are guided by modern safety requirements - connecting circuit breakers, fixing RCDs in appropriate areas, stabilizers and transformers.

But in most rooms, wiring was installed more than 30-40 years ago. Therefore, there is no protection against voltage surges, energy surges - there are only Soviet-style plugs. However, for devices with electronic filling, connecting to the network through such power points is fraught with quick breakdown - any failure will cause burnout of the board and electrical elements. Electricians recommend installing modern outlets with built-in voltage control or RCDs.

With increased ease of use

Some models are equipped with additional features that can solve a number of problems. Timer - allows you to set the time for disconnecting the device from the network, just set the required time on the outlet. There are mechanical and electronic options.

An extension cord is an ordinary socket with a wire that is hidden in the wall. The socket box needs to be cut to a larger size, but such an extension cord will not be lost and will not take up space during storage.

Childproof

Such protection is installed in two versions - plastic shutters of the sliding and rotary types. The first opens with simultaneous pressure with the plug of the device. In the second variant, it is necessary to pry off the upper protective frame and turn it, after which the inlets appear.

Design features

The models of recent years have special design elements that greatly differ from the original mechanisms. The principle of operation - connection to the electrical network - remains the same. Additional points - the “smart home” system, control from the phone (for example, turning on and off the fireplace) - are familiar to few. For standard rooms, these features are not important, but if you plan to install the latest systems, other sockets will not work.

Types of electrical outlets in different countries

In some countries, the plugs have three plugs, and the cross section may differ. For example, in Switzerland, three round triangular plugs are used. In England, USA, Canada and other pins are rectangular (English), located in different places.

To select the optimal outlet, you need to know the total voltage of the network, the level of current conductivity, the expected features ("smart home", outlet block, other functions). If in doubt when choosing and buying, you can consult the seller or the master.