To ensure uninterrupted power supply, it is important to take care of the reliable connection of the wires with sleeves. Twisted joints in electrical wiring are common. At both ends, the twist points oxidize after a while and heat up strongly under heavy loads, which is fraught with short circuit and spontaneous combustion. It is also important to consider that due to the electrochemical properties of aluminum and copper, they cannot be connected directly. Special crimping sleeves for connecting wires are able to provide the most reliable crimping.

What is crimping of wires with sleeves

Crimping is a common procedure in the electrician, its peculiarity lies in the connection of electrical wiring with special sleeves. A connecting tube made of metal is used as a connecting mechanism. To crimp the wires, their cores are wound with a sleeve. By crimping the tube with the wires inside, it is possible to achieve a reliable connection. At home, crimping is done with pliers, but it is preferable to use a special tool - press tongs.

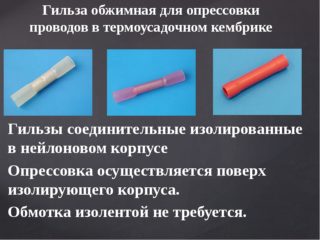

In two or three places, the sleeve is squeezed, and the crimped place is insulated using PVC insulating tape or heat shrink tubing. Sometimes insulated connecting sleeves are used to connect the elements, in this case there is no need to re-process the wiring section.

The connection of wires with sleeves must be carried out in the following cases:

- You need to connect wires with a large cross-sectional area.

- There is no possibility of using alternative methods of connecting the wire. For example, conducting wiring inside a junction box where visibility is poor at high altitudes or the terminal block cannot be placed.

- It is necessary to connect wires in lines with high load.

The crimp sleeve for wires has its own advantages and disadvantages. The former prevail:

- The crimping tool is equipped with a comfortable working area. This principle of operation allows you to perform the assigned tasks in a confined space, for example, in junction boxes or a socket box. Inside the socket, crimping the wiring contacts allows you to shorten the wires to an absolute minimum.

- Pressing tongs are used to compress the tube used. Unlike analogs, this tool does not require an electrical connection to work, it belongs to the group of manual tools. If power is not yet connected, crimping is the only reliable way to connect wires.

- To carry out soldering or welding, you must have certain knowledge and skills. Anyone can cope with the crimping after the first trial. At the same time, it is important to have press pliers and consumables; in extreme cases, there must be pliers.

Crimping allows you to connect wires made of different materials, for example, aluminum and copper. Soldering and welding does not provide such opportunities.

- The need to constantly have in stock and regularly replenish stocks of liners of various sizes.

- The connection is characterized by considerable dimensions, which sometimes complicates the implementation of some tasks.

Also worth mentioning is the tangible cost of consumables.

The principle of operation of the wire crimper

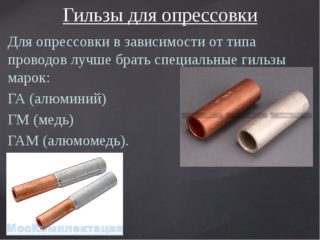

For crimping, an aluminum or copper wire is used. Based on this, a sleeve made of aluminum or copper should be used. There is also a copper-aluminum or connecting tube for strands of different materials.

Over time, the aluminum cable forms an oxidizing film, for this reason, the sleeve must be carefully cleaned and treated with a special compound. To protect the material from oxidation, quartz-vaseline paste is most often used. Copper wire also needs to be treated with special compounds. Thanks to them, the likelihood of damage to the wire core during crimping is reduced, and the friction force is also reduced.

Stranded conductors are aligned and folded so that they fit easily into the sleeve. The cable is inserted into the cartridge until it stops. You need to connect the elements not at the junction, but with a small plant.

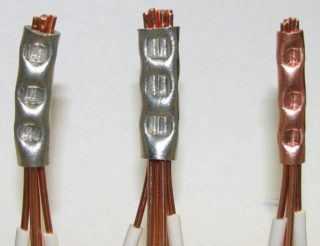

Sleeves must be used that are designed and calculated for the total cross-section of the cores to be crimped. If a press with local (point) indentation is used, 2-3 veins are made evenly along the entire length, this is necessary for reliable and high-quality electrical contact, as well as ensuring mechanical strength at the junction. When using square or hexagonal matrices, the same rules should be followed.

It is important to ensure that the sleeve does not crack during crimping, and also make sure that there are no squeezed cavities. After crimping, the junction is isolated with elbow cloth or electrical tape. The final step is to carefully fold the cable into the junction box.

The difference between crimping tubes for wires by material

Copper sleeves

The abbreviation GM indicates that the sleeve is made of high quality copper. Used exclusively for connecting copper wiring. The surface of the GM is not covered with a protective shell, therefore it can be operated only in non-aggressive environmental conditions.

Tinned sleeves

With the help of tinned sleeves, copper wires are connected, intended for operation in an aggressive environment. These are the same sleeves made of copper, only their surface is covered with a special compound that forms a white protective shell. The abbreviation is GML.

The advantage of tinning is to protect the material from electrochemical corrosion, however, it is prohibited to use GML for aluminum wiring. This is due to the fact that during the compression process the protective layer is partially destroyed, which will result in direct contact between aluminum and copper.

Connecting tubes for cores made of different materials

This variety differs in shape. This can be explained by the fact that the aluminum part of the tube has a larger diameter due to the need for a larger conductor cross-section.

The GAM crimping algorithm is similar to the previous methods.

There is another type of sleeves designed for crimping wires.Its difference lies in covering the surface with insulation. Their operation does not require additional use of connecting heat-shrinkable tubes or PVC tape. The surface of the sleeves is coated with a material that has plastic characteristics. During crimping, the PVC layer is also compressed, but there will be no direct contact between the sleeve and the wire.

Crimping tools

In any hardware store in the electrical goods department, a large assortment of sleeves is presented. Also, to complete the task, a crimping device is purchased. The most budgetary and demanded:

- The double-jaw equipment has the appearance of pliers, but is additionally equipped with a double-jaw compression reinforcement. There are also different types of jaws for crimping, such as round tips or fork tips. The average cost on the Russian market is 800 - 1000 rubles.

- The analogue of the previous device is four-lip crimpers. They are intended exclusively for liners. The cost is several times higher and already starts from 2000 rubles.

- Wire stripping device. There are several types and modifications depending on the material from which the wiring is made.

A cutter can also come in handy for making precise cuts. The price is more than acceptable, about 150 rubles.

Press pliers

The most common crimping tool for sleeves is the press pliers, which are used even for domestic purposes, since they can be used to crimp various terminals and non-standard connectors.

There are several types of press tongs, depending on the purpose:

- for crimping sleeves;

- to remove the insulating layer from the core.

The crimp design is divided into several varieties, their main difference lies in the size and shape of the sockets. The socket can be trapezoidal or square in shape. Also, the nests are divided according to additional equipment or the absence of plastic flanges. With their help, a reliable crimping of a multicore cable is carried out.

To obtain a reliable connection, it is necessary that the size of the tool corresponds to the diameter.

Crimping pliers modifications:

- A tool designed for non-insulated parts. Equipped with one rod, which is located at the dividing joint during the crimping process. Crimping the pipe itself should be carried out in the very center.

- Equipment designed for insulated parts. Equipped with three oval die press shapes. Each of them is inherent in blue, red and yellow. Insulated tubes are painted in similar colors to make it easier to select the required press.

Crimping sleeves are a type of permanent connection. To avoid installation errors, you need to have a wiring diagram in front of your eyes.