When placing network lighting devices (lamps or LED strips), as a rule, there is no doubt about how to connect them to each other. If they are designed for a voltage of 220 volts, the traditionally used method of switching on is a parallel connection. Serial connection of bulbs is used only in rare cases, when garlands are made on their basis, for example. Another common reason for using this method is the desire to increase the life of lighting products by using them at partial operating power.

Serial connection

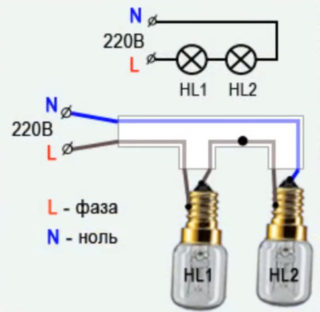

Atypical serial connection of bulbs to a 220 Volt network has the following characteristics:

- the same current flows through all the lighting elements included in the circuit;

- the distribution of voltage drops across them will be proportional to the internal resistances;

- accordingly, the power consumed by each illuminator is distributed.

When lamps are connected in series in a circuit with a common switch, illuminators designed for 220 Volts will not burn at full strength.

When two incandescent bulbs with different power P are installed in a chain, the one that has high resistance, that is, less energy-intensive, burns brighter. This is explained very simply: due to the higher internal resistance, the voltage across it will be more significant in magnitude. Since this parameter is included in the formula for P in the square P = U2 / R, then at a fixed resistance, more power is dissipated on it (it burns brighter).

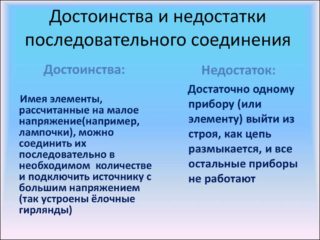

- if one lamp fails, the entire circuit is de-energized, so that the lighting line completely stops working;

- when installing bulbs of different power, they give a different glow;

- the inability to use a sequential circuit when connecting energy-saving lamps (they need a full voltage of 220 volts).

The sequential version is ideal for creating "soft light" in wall lamps or in the manufacture of garlands from low-voltage LED elements.

Parallel connection

The classic parallel connection of lamps differs from the serial method in that in this case full mains voltage is applied to all fixtures.

When the light bulbs are connected in parallel, "its own" current flows through each of the branches, depending on the resistance of this chain.

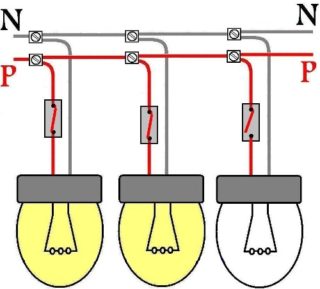

The conductors leading to the lamp bases and sockets are connected to one wire in a parallel assembly. The indisputable advantages of this method include the following features:

- when one of the bulbs burns out, the rest continue to work;

- in each of the branches they burn at full power, since full voltage is applied to all at the same time;

- it is allowed to use energy-saving light bulbs;

- to connect to the network, it is enough to remove the required number of phase conductors from the room chandelier and arrange them in the form of a switched group.

There are practically no drawbacks to this method, with the exception of the high consumption of conductors with highly branched circuits. You can easily connect several bulbs to one wire using the wiring principle. A typical scheme for parallel connection of light bulbs with a switch is no different from a conventional switch. In this case, a key switch is additionally introduced into it.

Mixed compound laws

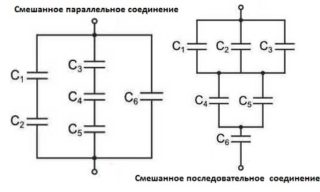

Mixed switching on of fixtures is described as follows:

- It is based on the parallel connection of several electrical branches.

- In some of the branches, the loads are switched on in series in the form of a series of lamps located one after the other.

It is allowed to connect various types of consumers to separate parallel branches, including incandescent lamps, as well as halogen or LED sources.

When considering the features of a mixed compound, the following laws must be taken into account:

- The same current flows through each of the series-connected sections of the circuit.

- When passing through a link with parallel connected consumers, it branches, and at the output it again becomes single-line.

- With an increase in the number of elements in the working circuit, the absolute value of the current in it decreases.

- The voltage on one link is equal to the product of the current component and the total resistance of the branch (Ohm's law).

- With an increase in the number of elements in the circuit, the voltage on each of them decreases accordingly.

The mixed connection method has a number of advantages, determined by the merits of each of the two basic connection schemes. From the serial one he "inherited" its efficiency, and from the parallel one - the ability to work even if an element fails in one of the combined chains.

It is recommended, when using a mixed circuit, to group lamps of the same power in series circuits, and to put illuminators with different power consumption in parallel branches.

Types of lamps and wiring diagrams

Before installing various types of lighting devices, it is advisable to familiarize yourself with the principle of operation and their internal structure, as well as with the features of the circuit for connecting to the supply network. It is also important to know that each of the varieties can work for a long time only with strict observance of the operating rules.

Fluorescent lamps

In addition to traditional incandescent lamps, their fluorescent tubular counterparts are often used to illuminate office and partly domestic spaces. They are most often installed at the following sites:

- in workshops and on conveyor lines of industrial production;

- in office buildings and in various boxes;

- in garages, sales areas and similar public places.

Much less often they are used at home - sometimes they are placed in the kitchen to organize the illumination of the working area.

A feature of fluorescent illuminators is the impossibility of direct connection to a 220 Volt network, since a high voltage is required for the breakdown of the gas column. To turn them on, a special electronic circuit is used, which includes such starting elements as a choke, a starter and a high-voltage capacitor (in some cases it is not required).

In recent years, choke converters that are uneconomical and humming during operation have been replaced by so-called "electronic ballast". The order of its connection is usually indicated in the form of a diagram shown on the body of the device.

When using an electronic adapter, one gas-discharge lamp is connected, or two pieces are installed at once, connected in series.

Halogen sources and LED lamps

Luminaires of the first type are traditionally installed when installing suspended and stretch ceilings.They are also ideal for lighting areas with high humidity, as they are available in several versions. One of them is designed to work from 12 volts. To obtain them, a converter is installed in the area of \ u200b \ u200bthe ceiling slabs, designed for the corresponding output voltage.

LED lamps are characterized by the presence of a built-in driver, which allows obtaining the required supply voltage (12 or 24 Volts). Samples of LED illuminators, designed to operate from 220 volts, turn on like incandescent lamps. But unlike conventional fixtures, it is not recommended to daisy chain them.

It is important to select the correct type of lamps to determine the correct order of their connection. It is not allowed to connect energy-saving illuminators in a serial chain; when installing fluorescent and halogen lamps, they are guided by their switching-on schemes. When the mains voltage is low, energy-saving lamps quickly fail, and fluorescent illuminators may not catch fire at all.

Consistently connected 60-watt and 100-watt bulbs, in the corridor, they have been shining for more than 30 years.

It all depends on the room that needs to be lit. Somewhere it is possible to connect lamps in series, somewhere in parallel. But this applies only to incandescent lamps. Serial connection can also be used for LDS lamps. But this option is rare.