Many owners of houses and apartments during construction and major repairs have to connect the chandelier to a two-button switch. A simple solution is to invite a specialist. But, for each service you have to pay and wait for the master to find the time for this. In addition, the hired worker may not be a professional and damage not only the device, but also burn all the wiring. By following simple rules, you can quickly and easily connect a multi-track luminaire via a multi-key switch.

Primary requirements

The main requirement when working with electrical devices is compliance with safety measures.

- The tool must have good insulation on the handles. The recommended level of protection is 1000 V.

- Before installation, the room must be de-energized. To do this, you need to turn off the packet switch in the general panel. The key breaks the circuit on one wire only.

- The connection of the switch must be carried out through a phase gap.

Before installation, you must first find the wire through which the current is supplied. If you insert a breaker into the break in the neutral conductor, this will lead to a polarity reversal. As a result, the lamps will be under constant voltage, regardless of the position of the keys, which is fraught with electric shock when replacing them. Another side effect is that LED and fluorescent lights glow and flicker when the switch is off.

To connect the chandelier, you must have the following tools and materials:

- screwdrivers (straight and cross);

- nippers;

- pliers;

- sharp knife;

- indicator (tester);

- insulating tape;

- marker.

It is advisable to purchase mounting goggles to protect the eyes from damaging short circuit factors.

Wire marking

To prevent installation errors and speed up work, manufacturers use generally accepted wire marking methods.

In modern cables, the following methods of coloring the insulation are used:

- grounding - yellow-green;

- zero is brown;

- phase - blue.

Older houses used aluminum wiring with white insulation. The cable can be two-wire or three-wire. It should be borne in mind that grounding is not provided in such gaskets. Depending on the number of cores, they always have 1 zero and 1-2 phases. Determination of the wire belonging is carried out by taking measurements directly on the connected line.

There is no such need for new buildings. They contain multicore cables with standard markings. In this case, the grounding may not be connected. Such an engineering decision is made with a future perspective, if the board of the house during its operation will ground the power supply system.

Phase detection on the ceiling

If in a new type of cable the search for a grounding conductor does not cause any difficulties, then with old wires the situation is different. If this line was originally installed, in most cases the property owners did not use it. At that time, there were no grounded chandeliers. An insulated conductor bent to the side is a sign of the presence of a grounding contact. In some cases, the owners simply cut it off to avoid future confusion.

After determining the ground, you need to find the phase.This is done using a screwdriver indicator or tester. When in contact with a phase, the indicator will light up, and the measuring device will show the voltage level in the network.

At the end of the measurements, you need to mark the conductors in any convenient way, and bend the ground wire (if it is not planned to use it) to the side and insulate. So it will not interfere with work and will not provoke a short circuit.

Continuity wiring

Dialing a line is carried out for several purposes. First of all, this is necessary to determine its integrity, the absence of breaks and bad contacts. If defects are found, the wiring must be changed. Secondly, the continuity test allows you to determine the correct connection of the wires in the switch block. In the open state, there must be a phase on one of the terminals of the device. If not, the installation was not carried out correctly. One should not exclude the version of making an error when switching the junction box.

When making a dialing by the indicator, extreme care must be taken so as not to connect the adjacent contacts with a probe. If there are errors in the assembly, it will lead to a short circuit. Measurements are taken alternately on each core. If they are connected correctly, there will be 1 zero, and the rest will be phases. The presence of voltage will be indicated by the activation of the spotlight inside the device.

More accurate readings that exclude stray voltage are given by the tester. Before testing, the device must be switched to voltage measurement mode. After that, you need to find the channel through which the current is supplied. This will be indicated by the readings on the display. Then you need to find a neutral wire. Holding the probe on it, one should alternately, switching the keys, determine the characteristics of the cores.

Chandelier connection wires

There are such options for switching wires:

- Twisting. Pliers are used to achieve a tight fit. Then the metal is wrapped with insulating tape.

- Soldering. It is the most reliable and durable way. Its downside is that it is extremely difficult and dangerous to carry out such work at a height.

- Terminal block. The product provides a strong and corrosion-resistant connection of several lines on a common iron base, where the contacts are fixed with bolts. The device is indispensable when connecting a 6-light chandelier to a double switch. In such cases, twisting and soldering are almost impossible tasks.

In the process of switching, it is advisable to use a strong wire. It plays the role of a suspension on which the chandelier is suspended from the hook for the period of connecting the wires. Such a solution will allow you to do the work yourself, without involving an assistant, who also needs a support.

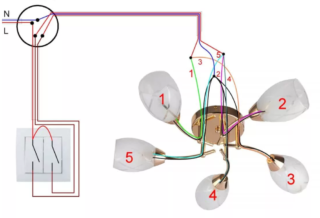

Connecting wires in a chandelier

When devices that have more horns than the number of active wires are connected to the network, the bulbs are grouped into groups. How many of them there will be in each is determined by practical and design necessity.There are many options, the most interesting is the scheme for connecting a two-button switch to the chandelier 1 + X, where 1 is the night or evening lighting on duty, and X are the rest of the lamps that create the main background. However, each property owner chooses the combination himself. The creation of groups is carried out by twisting channels with isolation of the same color.

The options for activating a 3-light chandelier on a double switch can be 1, 2 and 3 activated by the consumer. 2 and 1 active wires from the device to phases, and 3 neutral wires to zero.

When installing a product with 4 shades, combinations can be 1 + 3 or 2 + 2. Here the algorithm is the same as with 3 shades: 2 cores per phase, 4 passive to zero.

Connecting a 5-light chandelier to a double switch can be done in combinations:

- 1 + 4;

- 2 + 3;

- 5.

The difference with the previous options lies in the composition of the groups. First, the zeros are connected with a five-arm device, then the twists are fixed at the phases in one of the selected ways. If it is necessary to use all 5 lampshades, the active wires are connected to the right or left button.

A six-arm lamp can work according to the following scheme:

- 1 + 5;

- 2 + 4;

- 3 + 3;

- 6.

Installation is carried out in the same way as all the previously described processes.

If it is necessary to make night lighting, a single plafond is equipped with a low-power lamp up to 10 W.

Frequent connection errors

When carrying out electrical work, novice craftsmen make the following mistakes:

- ignoring the insulation of the grounding line;

- twisting copper and aluminum conductors directly;

- the use of cables with insufficient or excessively high power;

- output to the zero phase switch;

- insufficiently strong production of twists;

- mounting on an unstable and uncomfortable base.

The key to success lies in compliance with safety measures and thoughtful preparation for work.