High-quality uniform lighting can be created using different light sources. Energy-saving fluorescent lamps are being actively installed in homes, offices, and factories. Their installation and circuit are more complicated than those of incandescent bulbs. For correct installation, the master must know how the device functions, what types there are and what circuit to use for connection.

- Lamp device

- Principle of operation

- Connection methods

- Electromagnetic ballast circuit (EMPRA)

- Two chokes and two tubes

- Connecting two lamps from one choke

- Electronic ballast circuit

- Voltage multiplier circuit

- Connection without starter

- Diagram with a series connection of two lamps

- Replacing fluorescent lamps

- Functional check

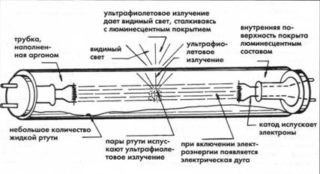

Lamp device

A luminescent counting source is a lighting fixture in which ultraviolet radiation is converted into visible light of a specific spectrum. The glow is achieved due to the electrical discharge that appears when electricity is supplied in a gaseous environment. Ultraviolet light is formed, which affects the phosphor. As a result, the bulb lights up and starts to shine.

Most fluorescent lamps are manufactured in the form of cylindrical tubes. More complex bulb geometries may be encountered. Tungsten electrodes are located along the edges of the tube, which are soldered to the outer pins. It is to them that voltage is applied.

The flask is filled with a mixture of inert gases with negative resistance and mercury vapor.

The standard light bulb circuit consists of a starter and a choke. Additionally, various control mechanisms can be used. The main task of the choke is to generate a pulse of the required magnitude, which can turn on the lamp. The starter is a glow discharge in which the electrodes are in an inert atmosphere of gases. A prerequisite is that one electrode must be a bimetallic plate. If the lamp is off, the electrodes are open. When voltage is applied, they are closed.

The classification is carried out according to different criteria. The main one is light. It can be daylight or white with different color temperatures. The division is also made across the width of the tube. The larger it is, the higher the lamp power and the area of the illuminated area. Fluorescent lamps are divided according to the number of contacts, operating voltage, presence of a starter, shape.

Principle of operation

The supply voltage is applied. At the initial moment, no electric current flows, since the medium has a high resistance. The current moves in spirals, heats them up and is fed to the starter. A glow discharge appears. After the contacts are heated, the bimetallic plates are closed. The temperature on the bimetallic part drops and the contact in the network opens. This leads to the fact that the choke creates the necessary impulse as a result of self-induction, and the lamp begins to shine. The arc discharge is maintained by thermionic emission occurring at the cathode surface. The electrons are heated by the current, the magnitude of which is limited by the ballast.

The light appears due to the fact that a special substance is applied to the lamp - a phosphor. It absorbs ultraviolet radiation and produces a specific gamut of light. The color can be changed by applying phosphors of different composition to the flask. They can be from calcium halophosphate, calcium-zinc orthophosphate.

The main advantages of the lamp are energy saving, long service life, bright glow.Among the shortcomings, one can single out the impossibility of direct connection to the network and the presence of mercury inside the flask. Lamps are more expensive than incandescent bulbs, but cheaper than LED light sources.

Connection methods

There are various options for connecting a fluorescent lamp to the network. The most popular fluorescent luminaire circuit is the connection using an electromagnetic ballast.

Electromagnetic ballast circuit (EMPRA)

The principle of operation of this circuit is based on the fact that when voltage is applied in the starter, a discharge occurs, leading to the closure of the bimetallic electrodes. The electric current in the circuit is limited by the internal inductance. This leads to the fact that the operating current increases almost 3 times, the electrodes heat up sharply, and after a decrease in temperature, self-induction occurs, leading to the ignition of the starter fluorescent lamp.

Cons of a fluorescent lamp circuit with EMPRA:

- High energy costs compared to other methods.

- Long startup time - approx. 1-3 seconds. The higher the wear on the light bulb, the longer it will take to light.

- Doesn't work at low temperatures. This leads to the inability to use in a basement or garage that is not heated.

- Stroboscopic effect. Flickering negatively affects human vision and psyche, therefore, such lighting is not recommended for use in production.

- Humming when working.

The circuit provides one choke for two bulbs. Its inductance is sufficient for both light sources. The starter voltage is 127 V; for a luminaire with one lamp, a voltage of 220 V is required.

There is a circuit of a 220 V fluorescent lamp with a throttleless connection. It lacks a starter. Such a starterless connection is used when the filament near the light bulb burns out. The design also includes a transformer and a capacitor for current limiting. For lamps with a burned-out filament, there are circuit alterations without a transformer. This makes construction easier.

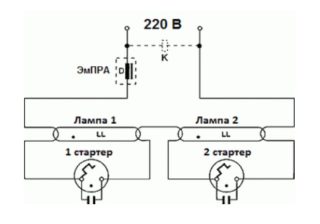

Two chokes and two tubes

This method is used for two lamps. You need to connect the elements in series:

- Phase - to the choke input.

- From the throttle output, connect one contact to the first lamp, the second to the first starter.

- From the first starter, the wires go to the second pair of contacts of the first lamp, the free wire must be connected to zero.

The second lamp is connected in the same way.

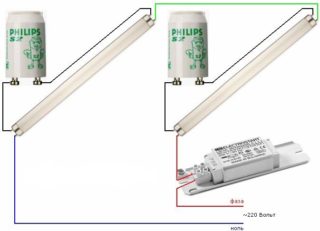

Connecting two lamps from one choke

This option is used infrequently, but it is not difficult to implement it. The two-lamp series connection is distinguished by its economy. The implementation will require an induction choke and a pair of starters.

Connection diagram for fluorescent lamps from one choke:

- A starter is connected to the pin output of the lamps in parallel.

- Free contacts are connected to the electrical network through a choke.

- Capacitors are connected in parallel to the light sources.

Budget switches can periodically stick due to increased starting currents. In this case, it is recommended to use high quality switching devices. This will ensure long and stable operation of the fluorescent lamp.

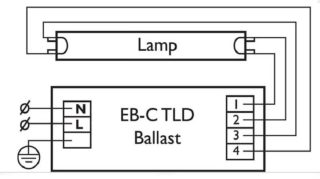

Electronic ballast circuit

All the disadvantages of EMPRA led to the fact that I had to look for another way to connect. As a result, the electromagnetic ballast was replaced by an electronic one, operating not at a mains frequency of 59 Hz, but at a high frequency of 20-60 kHz. Thanks to this solution, blinking of light is excluded. Such schemes are used in manufacturing.

Visually, the ballast is a block with terminals. Inside there is a printed circuit board on which the electronic circuit is assembled. An important advantage of electronic ballast is its miniature size. You can even place the block in a small light source. Also, the startup time is shorter, and the device works silently.The electronic ballast method is also called starless.

It is not difficult to assemble a diagram of such a device. It is usually located on the back of the instrument. The diagram indicates the number of lamps for connection, all explanatory inscriptions, information on technical characteristics.

How to connect a fluorescent lamp:

- Pins 1 and 2 - to a pair of contacts from the lamp.

- Pins 3 and 4 are for the remaining pair.

The input must be supplied with a supply voltage.

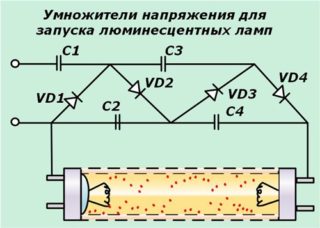

Voltage multiplier circuit

This circuit allows you to straighten the voltage and double it. The lamp lights up immediately. To implement the circuit, you need to choose the right capacitors. 1 and 2 are selected for 600 V, 3 and 4 - for 1000 V. The disadvantage is the large size of the capacitors.

Connection without starter

The starter causes additional heat to the fluorescent lamp. It also often fails, which is why this part has to be replaced. There are schemes in which a fluorescent light source works without a starter. The electrodes are heated to the desired level using transformer windings that act as ballast.

When buying a light bulb, you need to pay attention to the RS inscription - quick start. It is these products that work without a starter.

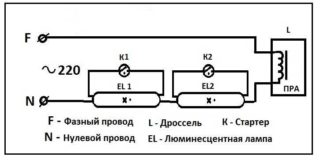

Diagram with a series connection of two lamps

There are two lamps that need to be connected in series with one ballast. To carry out such work, the following components are required:

- Induction choke.

- Two starters.

- Two fluorescent lamps.

The connection diagram for the fluorescent lamp is as follows:

- A starter is connected to each lamp in parallel to the pin input at the end of the bulb.

- The remaining contacts should be connected to the electrical network through a choke.

- Capacitors are connected to the contacts of the lamps. They are necessary in order to reduce the intensity of interference and reactive power.

Capacitors are selected based on the load.

Replacing fluorescent lamps

The fluorescent light source differs from the classic halogen lamps and filament products with a long service life. But even such reliable light bulbs can fail, which is why they have to be replaced.

The replacement can be done as follows:

- Disassemble the lamp. It is important to carefully remove all parts to prevent damage to the instrument. The fluorescent tubes must be rotated around the axis in the marked direction. It is indicated by arrows on the holder.

- After turning 90 degrees, the tube should be lowered. Then the contacts will easily come out of the corresponding hole.

- Visually inspect the integrity of the light bulb, filaments. If there are no visual problems, the failure could be caused by internal components.

- A new light source should be taken. Its contacts must be upright and fit into the hole. After installing the light bulb, it must be scrolled in the opposite position.

Remove the device carefully so as not to break the glass flask. Inside there is mercury, which is hazardous to health.

After the system is assembled, you can apply the supply voltage, turn on and start testing. The final step is to install the protective cover on the luminaire.

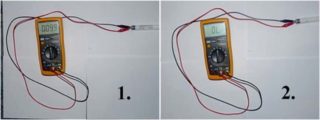

Functional check

You can check the assembled system using a tester that checks the filament. Its allowable resistance must be 10 ohms.

If the test device shows infinite resistance, the bulb is only suitable for use in cold start mode. Also, infinity can be displayed in case of a malfunction of the light source.The normal resistance that the tester should show reaches several hundred ohms. This is due to the fact that in the normal state, the starter contacts are open. In this case, the capacitor does not pass direct current.

If you touch the throttle leads with the multimeter probes, the resistance will gradually drop to a constant value of several tens of ohms.

The exact value cannot be determined using a conventional tester. But some instruments have a function to measure inductance. Then the values can be checked according to the EMPRA. If they do not match, you can judge about problems with the device.

Lamps with a filament resistance of more than 5 ohms do not always light up or may be unstable.

In the voltage multiplication circuit, they forgot to include a balanced resistor of about 200 Ohm and a power of about 10 watts. Without it, the diodes will heat up and fail immediately.

Turn on the choke, instead of the capacitor c1 and it will be better to ignite

"The electromagnetic ballast was replaced with an electronic one that does not operate at a mains frequency of 59 Hz ...". The network frequency according to GOST is (50 ± 02) Hz. “After turning 90 degrees, the tube should be lowered. Then the contacts will easily come out of the corresponding hole. " Isn't it easier in a "new" lamp on its caps to draw two lines with a marker opposite its pins? Backfill question: why in a fluorescent lamp with an electromagnetic ballast, a "spiral" connected to a phase conductor wears out faster? There was even a recommendation - to periodically change the connection of the spirals.