A set of three outlets in one housing allows you to connect a large number of devices to a single power source. The three-module device also reduces the number of wires used. The triple outlet is in demand in the kitchen, bedroom or study.

- The need to install triple sockets

- Varieties of products

- Features of a socket with a switch

- Triple socket design

- Electrical connection

- Components for assembly

- Installing the socket

- Wall surface marking

- Drilling holes in the wall

- Fixing the socket in a concrete wall

- Connecting triple sockets

- Features of connection with and without grounding

- Safety instructions

The need to install triple sockets

The use of a three-module socket allows you to use household appliances and electrical appliances with comfort. The joint mechanism has a number of advantages:

- low cost in comparison with single-module products;

- durable and safe fasteners;

- no costs for organizing additional wiring;

- efficiency of repair in case of breakdowns;

- quick and easy installation.

When installing triple devices, you will need to drill a socket for three modules. This technique will significantly save space in the apartment and increase the functionality of the wiring.

Varieties of products

In terms of shape, size and installation method, there are the following sockets with three sockets:

- internal - suitable if the apartment has a hidden type of wiring;

- external - a built-in cover prevents dust from entering the holes, the case has increased protection;

- built-in and overhead - recessed into the wall surface.

Modern manufacturers produce models with grounding, without it, as well as with a fuse that provides shutdown at the moment of a short circuit.

Triple sockets have two types of contacts:

- petal during operation lose their properties of rigidity and elasticity, they can spark;

- spring ones are characterized by increased wear resistance.

The optimum contact material is brass.

Features of a socket with a switch

Devices for three consumers with a shutdown button are convenient in that the switch de-energizes part of the electrical circuit. This eliminates short circuits or build-up of static electricity. The peculiarity of the device is a one-piece case with three slots and an off key.

The combined designs are different:

- versatility - they are installed on concrete, stone, wood and plasterboard type of walls;

- cost-effectiveness - a minimum of installation trenches and holes will be required;

- ease of connection - a common wire is pulled, and not a separate cable for each point;

- the speed of marking the surface due to the same dimensions of the products;

- the ability to simultaneously control light sources and turn on electrical appliances.

If one element fails, the entire unit must be replaced.

Triple socket design

Products are made on the basis of a body and a working part - terminals with springs for plugs and contacts, a grounding device. Modern euro sockets withstand amperage up to 16 A, standard - up to 6 A. Sockets in one case are distinguished by large diameter round holes for plug rods. The cover of the devices is made of heat-resistant plastic, the core is made of ceramics. A special horizontal and vertical panel is used for installation.

The modules are located on a common frame or on 3 independent ones connected by a common panel. To date, two modifications of the triple block of outlets are used:

- C5. Non-earthed design in square housing. Placed under old Soviet devices, connected to a 220 V network.

- C6. Euro socket, withstand voltage 230-380 V. Compatible with appliances with Euro plugs and plugs.

The blocks are suitable for arranging two types of wiring. Internal for hidden mains is mounted using a cylindrical socket into the walls. The external one is suitable for open power lines, it is installed on a plate socket on the surface.

Depending on the manufacturer, the triple module has a width of 212 to 220 mm and a height of 72 to 80 mm. The size of the device, including the cover frame, is 160 mm high.

Electrical connection

The structure should be connected taking into account the wire cross-section. For outdoor installation, the ability of the wiring to withstand 3 consumers is checked. The presence of separate socket boxes provides for additional cable laying vertically or horizontally. After these works:

- Separate socket outlets are connected to the cable clamps and clamped using the terminals.

- The ends of the conductors are twisted inside the device.

- The central part is installed and the cover plate is fixed.

When installing a socket to an existing group, the machine is replaced.

Components for assembly

The socket, suitable for three sockets, does not always meet the needs of the buyer or is expensive. The way out of the situation will be the self-assembly of the unit from single-module products.

A three-module can be made from the inner parts of standard sockets with a rated current of 16 A. The overhead frames are removed, the rest of the elements are put into a special overlay with three niches. It turns out a solid block.

Installing the socket

Installation of the block begins after choosing the location of the structure:

- in the kitchen, for a one-time connection of equipment, it is better to place the device above the countertop;

- in the bedroom, a three-module product can be installed behind the TV - the wires behind the screen will be invisible;

- when installing in a bathroom, a sealed moisture-resistant block is required, located 60 cm from the water.

After choosing the installation area, you will need to prepare tools - a level, a tape measure, a marker or pencil, a perforator with a crown nozzle and a nozzle for making strobes.

Perform installation work before finishing the room.

Wall surface marking

The geometry of the structure and the convenience of organizing the wiring depend on the correct marking. To outline the mounting points, start from the number of outlets in the unit. When working, use a level - it will ensure the evenness of the device.

The distance of the socket from the floor is 20-40 cm. Between the centers of the socket boxes - 72 mm. Otherwise, it will not be possible to accurately plant the decorative panel. The slitting is done strictly horizontally or vertically - it is better to draw the contour of the hole.

Drilling holes in the wall

You can make seats for the outlet by strobing with a perforator with different nozzles. A hammer, a chisel, and a few screwdrivers are used to refine the sections.

Drilling is carried out in stages:

- A drill or perforator with a nozzle makes a round hole. The crown should be completely immersed in the wall.

- The strobe is led strictly vertically or horizontally.

- The width and depth of the channels are made for the cable section or the size of the corrugated pipe.

- Remains of concrete are removed with a chisel.

- For gypsum boards or other soft materials, a special nozzle or a sharp construction knife is used.

- On the back of the socket case, three holes are made for wires.

- 2 holes are drilled between them for auxiliary wires.

The permissible cross-section of the cable for the socket is not less than 2.5 mm2.

Fixing the socket in a concrete wall

To make the triple socket fit snugly in the socket, white alabaster is used. Due to the quick setting of the material, the mixture is prepared in small portions. The density is controlled visually.

The landing niche for the socket is coated with a solution from the inside and its fastening is checked. The product will sit firmly on a dense mixture. If it fails, add more alabaster and reapply the composition. After installation, the solution should dry for 2-3 hours. The outer layer of the material is leveled with sandpaper.

Before planting the socket on the alabaster, check the horizontal and vertical position of the mounting screws.

Connecting triple sockets

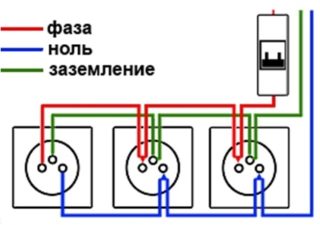

The triple built-in socket and the overhead device are connected according to the parallel principle:

- A diagram is drawn in which the zero, phase and grounding cables are marked in different colors.

- Phase and neutral are found with an indicator screwdriver.

- Turn off the power from the shield.

- Jumpers are made from one socket mechanism to another.

- The protection cable is thrown onto the grounding contacts (yellow-green).

- Zero (blue wire) and phase (red / brown wire) are connected to power contacts.

- The connections are secured with screws.

- The veins are twisted inside the box.

- Align the device by tapping on the body.

After tightening the fixing screws, decorative overlays are placed.

Features of connection with and without grounding

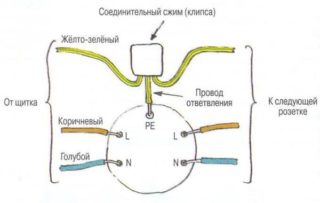

A triple outlet in one socket, if there is grounding, is connected as follows:

- De-energizing the room and checking the current flow with an indicator screwdriver.

- Dismantling the old socket. The central screw is unscrewed, the clamps are loosened, the product is carefully removed from the socket, the wires are disconnected or cut off.

- Debris will be removed from the niche.

- The upper insulation is removed from the cable with a layer of 20-40 mm from the end and stripped by 3-5 mm.

- The bare ends of the phases must be connected to the terminals and pressed with screws.

- The green-yellow cable is connected to earth ground and clamped with screws.

- The socket is put in place and fixed.

At the last stage, the housing cover is installed.

In old buildings, two-wire TN-C wiring with a phase and a neutral ground (PEN conductor) is laid. Connect sockets without grounding only after checking the voltage with a multimeter. Electric current is not supplied to the apartment at this moment. For installation, it is better to choose models equipped with a grounding mechanism. Complete safety will be ensured only by replacing the wiring.

Safety instructions

When deciding to connect a built-in module, be guided by the safety requirements:

- Turn off the electricity and break the circuit.

- Use devices, tools with rubber or plastic insulation on the handles.

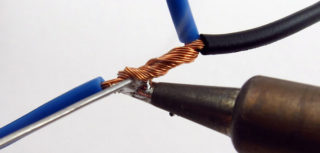

- Solder the wires together.

- Check the insulation of the cable, if necessary, place it in a plastic tube.

- Cut a long vein or twist it into a ring and hide it in the wall.

- Build up a short wire by hiding the pins.

- To prevent short circuits, check that the outlet and wire are correct for the power and current on the circuit.

- Install a triple module in a wooden house only in a metal socket.

- Position the module near the door so that the switch is closer to the opening than the socket.

Compliance with safety measures will help to perform the installation work in a quality manner.

The built-in socket strip is easy to use. If you have the skills and knowledge, the switching device can be connected independently. The main thing is to follow the sequence of work.