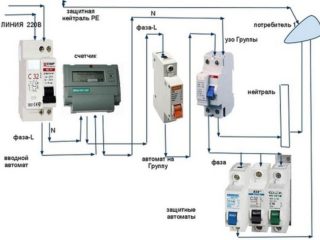

The electrical panel contains switching components and automatic devices, as well as equipment for connecting and distributing consumers over the network. For optimal performance of your duties, you need to choose the right installation wires and lay them correctly. The selection of the correct conductors and the correct connection will increase the safety of the wiring and ensure its long-term operation.

The composition of the electrical panel and its device

The electrical panel is a metal box containing various switching and protection devices. They are connected using special wires.

The lead-in cable is led into the electrical panel through a special hole. After that, the electrical equipment is connected and the wires are laid inside the shield. You need to connect the conductors according to the developed scheme.

The structure of a modern home switchboard includes the following switching and protective devices, as well as other types of products:

- Electricity meter.

- Automatic machines. They are installed at the entrance and on separate groups of energy consumers. Usually, a circuit breaker is chosen for the entrance, for the lighting group and for powerful electrical equipment in the apartment.

- RCD.

- Difautomats.

- Timer.

- Voltage and phase control relays.

- Other automation for control and monitoring.

The housing must be grounded, as well as metal doors and live parts. Otherwise, in the event of a current leakage, the shield will pose a potential danger to human life and health. The guard should be locked with a key to prevent access by unauthorized persons and to prevent electric shock.

Wire selection

All conductors can be divided into flexibility classes. This indicator depends on the construction of the cores. The higher the class, the more flexible the conductor. Monolithic conductors are difficult to bend and can break during operation, but they are easy to connect to the terminals. Multi-wire products bend better, are easier to work with, but the difficulty lies in the impossibility of connecting to terminals and screw terminals. To do this, you have to either tin the ends, or crimp them with special tips. Otherwise, the contact will be unreliable and will not last long. The choice of stranded or solid wire also depends on the flexibility class of the product.

For all the above characteristics, you can select a number of wires that are suitable for switching on. These include:

- PV-1. This is a product with a single-wire copper conductor, which has a single layer of PVC insulation. Flexibility class 1.

- PV-3. Stranded conductor with copper conductors, PVC insulation with 2 class of flexibility (for a cross-section from 0.5 sq. Mm. To 1.5 sq. Mm.), 4 class with a cross-section from 2.5 to 4 sq. Mm. and 3 class of flexibility for cross-sections over 4 sq. mm.

- PV-4. PVC insulated stranded copper cable. It is a more flexible analogue of previous products. Flexibility class 4 and 5.

You can pick up foreign analogs of wires. These include H05VJ, H07VK, designed for voltage 0.5 and 0.75 kV, respectively.

When choosing, you need to decide what section of the wire to make the wiring in the shield. It directly depends on the load in the room. It is recommended to take a wire for connection with the same cross-section as the supply cable. To connect an electric meter, cable products with a cross section of 25 sq. Mm are used. But you need to take into account another indicator - the maximum current strength for which the electric meter is designed. Depending on the brand, this is 50-60 Amperes, which corresponds to 10-12 kW. According to these criteria, a copper conductor with a cross section of 10-16 sq.mm is suitable. or aluminum wire, in which the cross-section will have to be increased to 16-25 sq. mm.

It is important to calculate in advance the cross-section of the wire for installation in electrical panels for connecting the machines and the length. The calculations should be based on the introductory machine.

Required tools

To securely make a connection in the shield, you need to purchase special tools in advance. They must be professional and have insulated handles. Mandatory tools include:

- Perforator.

- Bulgarian.

- Screwdrivers, including an indicator for checking the absence of voltage on the wires.

- Knife.

- Insulation stripper.

- Pliers.

- Nippers.

- Portable lamp.

After preparing the tool, you can proceed with installation.

Installation and connection

Before starting work, be sure to de-energize the room. With the help of a tester, it is checked whether the voltage remains on the conductors. Use the screwdriver probes to touch each core in turn. If the light does not light up, you can start working. It is forbidden to work when the electricity is on. It is also important to prepare the tools in advance and provide the master with an autonomous light source.

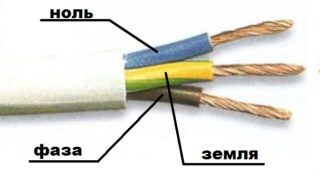

When connecting wires in a panel, it is important to remember that the colors of the cores indicate their purpose. The core can be completely colored in one color or another or have a color mark at the entrance to the device, that is, at the ends of the conductor. The following gamut is used:

- Phase - gray, black.

- Zero is blue.

- Grounding is yellow-green.

The wire for the installation of the electrical panel must be laid in such a way that there are no sagging and unnecessary bends. To do this, the length of each segment is determined in advance with a small allowance of 2-3 cm.

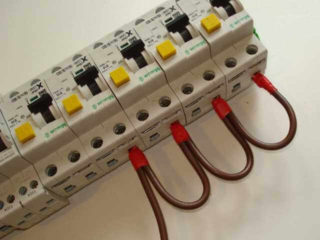

All connections to the machine are made using jumpers. A single-wire rigid wire can be used for this purpose. If possible, it is better not to use jumpers, but to do everything through the connecting core. Thanks to her, the contact will be reliable, and the appearance is aesthetic.

It is not recommended to connect more than two wires in one block. If this cannot be avoided, the cables must have the same cross-section.

Jumper preparation and wiring diagram

The conductors must be prepared for connection in the shield. To do this, you need to strip the ends of the insulation with a knife or a special tool. The cores should be inserted into contact and tightened well with a screwdriver.

During work, you need to watch out for the following:

- The insulation must not get caught in the clamp.

- The exposed part of the wire should not protrude from the contact over a large area. Such a requirement is made by network organizations that are engaged in sealing meters. This prevents illegal connections from outside.

- Tighten the top screw first, then the bottom screw.

The last step is to check if the fixation is reliable. The veins must be gently touched and spread apart. The handler must not sway or wobble.

Next, you need to connect the neutral wire. It is connected with a jumper from the lower right contact of the automatic double-pole switch to the third contact of the electricity meter. The ends also need to be stripped of insulation, connected and tightened with screws. The wires must not touch each other.Be sure to make a gap between them.

Now you need to connect the outgoing wires from the meter. First, a phase is connected through a jumper to the upper contact of the machine. The ends are stripped and attached. The phase also needs to be distributed among the other sources along the directions of the machines.

There should be one contact from the electric meter in the apartment. This is the outgoing zero contact, which should be connected to the zero bus. It usually comes with a plastic box. Length, dimensions and configuration vary by manufacturer.

Basic rules for wiring

All of the above actions must be performed in accordance with the rules adopted by the PUE. Failure to comply may result in negative consequences, including electric shock and possible short circuits.

Primary requirements:

- The terminal box, junction boxes, the meter should be mounted in easily accessible places.

- The wires must not cross, there must be a distance between them.

- The cross-section of the wire in the shield for connecting machines, RCDs and other products is selected depending on their current load.

- A plan for the location of the conductors should be created.

- The wires should not touch metal parts and building structures.

- All connections in the junction box must be securely insulated.

- Protective and neutral wires are attached to the devices using a bolted connection.

During work, it is imperative to follow safety precautions. The foreman must wear protective dielectric gloves and goggles.

A rasoska (special jumpers) is placed between the machines and sold in stores.

Where did you read that the cross-section of the wire in the shield for connecting machines, RCDs and other products is selected depending on their current load? Have you tried to read the PUE (TKP)? etc.