When replacing a switch or installing a new one, you should figure out how to connect the light switch to the light bulb. The circuit for connecting the switch to the light bulb has different versions, from which you can choose the most convenient. Proper preparation for installation work is also important.

- Measures to ensure electrical safety

- Tool for work

- Recommended cables and wires

- Junction box application

- Removing insulation from wiring

- The nuances of twisting formation

- Switch installation

- Varieties of household switches

- Types of lamps for home use

- Ways to power a light bulb through a switch

- Simplest luminaire connection

- Lamp one, two switches

- Errors and malfunctions

Measures to ensure electrical safety

Before you start connecting the devices to each other and to the electrical network of the apartment, you need to take care of preventing traumatic situations and damage to the wiring.

Step by step sequence:

- De-energize the branch of the network where the work will be carried out. This can be done by turning off the switch of the required group or the main one in the input panel.

- Prepare a stable table on which manipulations will be carried out at high heights. Due to the lower risk of injury, it is more suitable for this than a stirrup ladder.

- For the duration of the work, a warning sign "Do not turn on" should be placed near the dashboard. This is especially important in cases where the location of the shield has a high probability of intrusion by outsiders.

- Check the absence of voltage at the bare contacts of the wiring and devices. This can be easily done with a screwdriver with an indicator. Before de-energizing, check its operability from the switched on network. You can use a multimeter.

You can also check the absence of tension with the outer side of the hand - the skin must be absolutely dry, free from wounds and other integrity violations. This place is distinguished by its high resistance to electric current compared to other parts of the hand.

Tool for work

You will need to prepare the toolkit:

- pliers,

- well sharpened knife,

- thin and regular slotted screwdrivers,

- nippers.

It is good if you can find a tool with special slots to remove the insulating material from the wires. It is also worth having on hand a drawn light bulb connection diagram and think over the sequence of work.

Recommended cables and wires

Intending to lay the lighting network and then connect the light bulb from scratch, it is better to choose VVGng cable elements with single copper conductors of 1.5 mm2, covered with a flame-resistant insulating material. It is best to comply with the accepted correspondence of cable colors to their functional purpose - this will make it easier to maintain the network in the future. The wire intended for grounding must have a yellow-green color, the working zero must be blue, and the phase cable must be any other than these two.

If the house has old aluminum wiring and a fragment of the lighting line needs to be replaced, the cable cores must also be made of this metal - when they come into contact with copper inside the junction box at the point of twisting, both wires will oxidize. The APPV 1.5 option is suitable. But if it is possible to make a configuration with clamps instead of twisting, it is permissible to use a copper cable.In this case, it is definitely not worth using products with multi-wire veins.

Junction box application

No wires run from the panel directly to the electrical appliance or from the switch to the lamp. Outgoing lines and lines directed to the device are switched in special junction boxes. Inside such a structure, there is usually a free space where it is supposed to form and place a structure from cables belonging to several lines and connected to each other by twisting. For a more reliable grip, it is advisable to scald the tail sections. Copper wires are allowed only to be soldered.

Before laying bare contacts inside the junction box, cover them with insulating tape to prevent metal parts from touching.

Instead of flying, you can use special clamps for insulation. If the box has screw-type terminals, they are also used in the contacts. Traditional clamps can be used if the box space is large enough to accommodate the combined cable terminations.

Removing insulation from wiring

The outer layer of insulating material on the cable ends is removed with the sharpest possible knife. First you need to make a longitudinal incision 3 cm in length. Then they take a bunch of loose ends of the wires in their hand, and with the other they sip a cut shirt, which will crack spontaneously in the process. The length of removal should be as long as the socket holder, junction box or luminaire housing can accommodate. Some stock is not a problem - it can be useful in the future if the contacts burn. The shirt is carefully turned inside out and carefully trimmed in a circle.

It is best to strip the veins with a special stripping device. If not, a sharp knife or biting pliers will do. The procedure should be performed as carefully as possible, shallowly plunging the working surface of the tool into the insulating material. It is necessary to ensure that it does not touch the conductive metal: in this case, the wire will break. This can happen both before the start of installation work, and after.

The length to which the wires are stripped depends on the connection method. Minimum for screw terminals: often 7-10 mm is sufficient in this case. Twisting with the lighting device wires requires a length of 20-30 mm. When placing twists in a junction box (especially if they are not planned to be soldered or welded), a large length is needed - 30-50 mm.

The nuances of twisting formation

Making a configuration of a pair of wires, their bare ends are laid crosswise. The intersection point should be located near the point where the insulation begins. After that, the ends are squeezed with your fingers and twisted. At the end, squeeze with pliers.

If the number of wires to be connected is more than two, they work with them according to the same principle. If the configuration is long, it can be folded in half and tightened with the tool, so that less adhesive tape was used for processing. They begin to lay the latter from the lower edge of the insulation and go down. Having reached the ends of the bare tails, they make 2 additional turns "in reserve", bend it into a twist to protect it and wind the second row from the bottom up. Several turns must necessarily cover the factory insulation.

Switch installation

Devices are of two types - intended for outdoor installation and for indoor. Models of the first type can be mounted on different types of surfaces without additional insulation devices. The latter require the installation of socket outlets in previously prepared rounded grooves.

It is considered correct to fit the switch when the light is turned on by pressing the upper area of the key, and turned off using the lower one. In this case, even a small resident will be able to quickly turn off the lamp with a downward movement of the hand.

On the switch from the junction box, there must be a wiring that serves as a phase. The main task of the device is to interrupt the phase circuit so that there is no voltage on the lighting device when it is off. If the switch device allows, inside it the phase cable is connected to the upper contacts, and the outgoing wires to the lower ones.

Varieties of household switches

Devices come with one and two buttons. The first works in binary "on-off" and is designed to control a single luminaire. The second allows you to control a pair of independent lighting circuits. There are switches that are sharpened for three circuits.

According to the internal structure, several varieties are distinguished:

- dimmers - perform the functions of switching on and off and control the degree of brightness of the lighting by means of a button or handle;

- devices with a pair or three keys and step regulation of lamp burning;

- pass-through devices with a single button that change the phase between two cables - when voltage is applied to one of them, it is cut off from the other;

- cross one-button, in which changing the position of the button allows you to connect the lines in a cross way instead of a straight line;

- sensory - not equipped with lever mechanisms, electricity is supplied and turned off when the body is touched with fingers.

There are devices with a sensor that react to a resident passing by.

Types of lamps for home use

Traditional are round incandescent bulbs with a tungsten spiral mounted inside. Halogen devices differ from them in that instead of creating a vacuum, the corresponding gas is pumped into the flask. This reduces the size of the lamp and extends its life. But it must be installed very carefully, in no case touching the glass with your hands.

Another category of lamps is energy saving. They are fluorescent and use grouped LEDs as lighting elements. The second type can be mounted in standard screw-on cartridges.

Ways to power a light bulb through a switch

There are several options for connecting a lamp with a switch: a traditional one-key, with two buttons, two switches, and others. The master needs to choose the most suitable one for the purposes of the tenant and the device of the home electrical network.

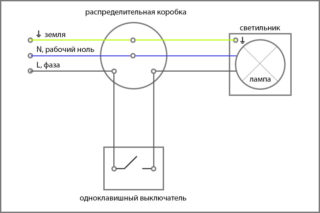

Simplest luminaire connection

The simplest wiring diagram is to connect the luminaire to a device with one button, which performs exclusively the operations of turning on and off the light. It will fit a single lamp fixture. This configuration requires a pair of wires. If the old wiring has only two power cables sticking out, and it is difficult to rebuild the home network, it is permissible to connect a device with several lamps. But then, when you turn on the light, all the bulbs will light up at once.

It is possible for such a structure to use a dimmer with control of the brightness of lighting, but it cannot be used in combination with a number of types of light bulbs (energy saving, daylight, LED devices). The switch must be suitable for use with the lighting fixture according to the power criterion.

It is permissible to install a sensor device with binary functioning, limited switching on and blocking of lighting. Such a switch is also powered via a pair of wires. You need to mount it in a socket box.

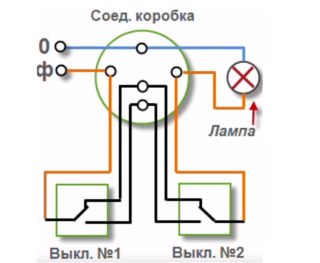

Lamp one, two switches

Owners of long corridors often need to connect two switches per light bulb in order to control the lighting fixture from both ends of the aisle. This configuration is also used when moving up a flight of stairs or in spacious rooms to control a lamp without getting out of bed. The disadvantage of this option is the ambiguity of the position of the on-off buttons.

If a third one-button switch is installed in the space between floors, independent lighting of the stairwells is realized. Then, by pressing the button, the previous device will be turned off, and the next one will turn on.

Errors and malfunctions

Sometimes, after the installation is completed, it is found that the lamp does not light up when the light is turned on. In this case, take a multimeter (or indicator screwdriver) and check whether the mains voltage is supplied to the switch by applying probes or sequentially touching the ends connected to the device with a screwdriver. If there is no power, the wiring in the junction box is incorrect. They are probably not twisted well enough. If a reaction occurs only on one of the contacts of the switch - the latter is faulty, a new one must be installed in its place.

If there is a suspicion of problems in the switch box, de-energize the line and re-twist the wiring connecting the phases of the switch and the main network, in compliance with safety requirements. At the end of the work, current is applied again and the function is checked.

Connecting a lamp to a switch is a simple procedure from the point of view of installation work, moreover, it has several configuration options. The user can choose the option that suits his needs.