In the process of organizing the electric line, modern and outdated cable connection methods are used. Twisting wires is the simplest way of fixing, but it is prohibited by the PUE. However, if you have knowledge of the correctness of the work, you can safely make a branch or additional fasteners. Such a connection will not lead to a short circuit in the future.

- Danger of twisting

- Pros and cons

- Varieties of twists

- Twisting of wires according to PUE

- The process of preparing the veins for twisting

- Twisting options for stranded wires

- Parallel connection

- Consistent seam type

- Bandage twist

- Features of twisting solid wires

- Wire twisting tools

- Operating procedure

- Connection isolation means

- Insulating tape

- Heat shrink tubing

- Construction insulating clamp

- Professional recommendations

- PUE allows

- Connecting conductors made of different materials

- The appearance of an oxide film

Danger of twisting

In clause 21 of chap. 2.1. PUE twisting is not prescribed among the methods of connecting wires. The rules allow the use of welding, soldering, clamps. The danger of twisting electrical wires lies in the following points:

- an increase in the contact resistance of the contacts with a weak tightening of the veins;

- weakening of the twisted section, leading to heating;

- an increase in current with weak contact;

- reflow of the insulation protection of the conductor;

- risks of short circuits, fire, human shock.

Despite the regulatory prohibition, most craftsmen resort to the twisting technique. This option is suitable for testing the operation of the line, performing a short-term network, for the period of repair.

Use special terminal blocks to twist the wires.

Pros and cons

The plexus of conductors is not designed to connect powerful devices - kettles, washing machines, heaters, refrigerators, computers. Despite this, twisting has several advantages:

- fast organization process;

- if done correctly - durability;

- no need for special tools;

- creation of signal contacts;

- additional reinforcement when using soldering technology;

- minimum costs for consumables;

- possibility of repeated execution.

Among the disadvantages are:

- mandatory insulation of the twisted section;

- normal operation of the line only when connecting low-power consumers;

- inconvenience of execution;

- risks of fire in the wiring if the algorithm is violated;

- constant voltage drops and overload of the twisted section.

Plexus is advisable when operating equipment with a weak power - lamps, power adapters.

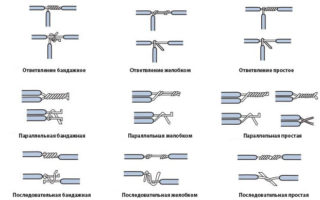

Varieties of twists

By correctly twisting the wires, you can get a reliable and dense section. Craftsmen use different types of connections - safe and durable:

- Bandage - an additional one is applied to two segments and braids around them. This creates additional reinforcement of the site.

- Groove - with the parallel technique, one core remains motionless, and the second is twisted around it. This type implies making 3-4 turns with one cable around the second. Then the first one is laid tightly parallel to the second and 3-4 turns are made again;

- parallel connection. Two conductors with insulation stripped at the same level are laid side by side. The tips cross tightly and curl in either direction.

All types of twists can be used as temporary fasteners.

Twisting of wires according to PUE

The rules for the installation of electrical installations say that for twisting, you can use a segment of 3-6 cm. The standards allow the connection of stranded and single-core cables with stripping of the ends by 4-8 cm. A stranded conductor must be laid on a single-core one and wound by 4 cm.

PUE establish the type of wire for a home line. The aluminum cable should be with a cross section of 2.5-4 mm2, copper - 1.5-2 mm2. The VVG and PV power cord is used only with a PVC sheath. ShVL and ShTB type wire with a cross section of 0.5-0.75 mm2 - with rubber or PVC insulation.

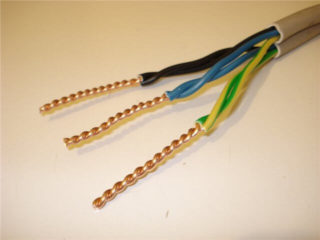

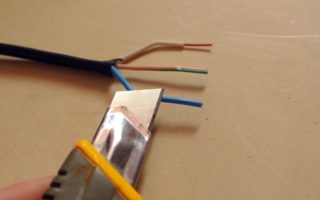

The process of preparing the veins for twisting

To twist the electrical wires, you will need to de-energize the network by turning off the introductory machine. Next you will need:

- choose a tool with insulated handles and gloves made of dielectric material;

- remove the insulating covering from the cores so that the metal part remains intact;

- wet a napkin in any degreaser (white spirit, acetone, nail polish remover) and wipe off exposed parts;

- sand the section of the core so that it acquires a characteristic metallic luster.

Twisting can only be started after preparation.

Twisting options for stranded wires

Stranded is a wire with a metal central part in the form of thin conductors. The elements are intertwined with each other, forming a lay with external insulation. Manufacturers can cover the wires with polyurethane, add nylon threads to improve strength. The protection makes it difficult to remove the insulating layer.

The twisting of insulated stranded wires is performed in several ways.

Parallel connection

The simplest option is when two stripped veins are laid cross-over, one by one. Only a section without insulation is allowed to twist. Parallel twisting provides reliable contacts, but is not force-proof.

The technology is suitable for copper conductors - one solid and one stranded. Aluminum conductors with different cross-sections are also allowed to be connected in parallel. In the case of a solid wire, you will need to remove more insulation than from a stranded one.

After twisting, a segment should remain, from which an additional bend is created in the direction of fixation. This technique increases the strength of the connection.

More than 2 wires can be fixed in parallel.

Consistent seam type

You need to fasten the wires together so that each of them overlaps the other:

- the conductors are stripped of the insulating coating;

- the cleaned elements are stacked on top of each other;

- twisting starts from the center so that one wire wraps around the second;

- the second contact is twisted in the same way.

Due to the minimum reliability, the connection is suitable for two cables.

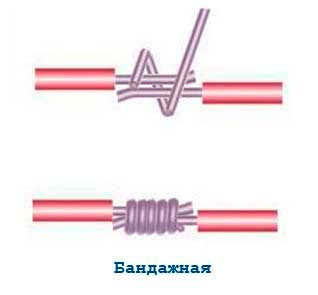

Bandage twist

The best way to fix a stranded wire is:

- two types of wire are selected - hard for fixing and soft for winding;

- insulation is removed from the cores so that the length of the bare sections is the same;

- conductors are laid in parallel;

- to fix the cores together, a third stripped wire is used.

Choose more than 2 rigid cables as twisted products. The winding is organized using a flexible soft wire.

Features of twisting solid wires

To twist solid wires tightly and correctly, a parallel connection will do. When performing work, it is necessary:

- remove insulation at an angle of less than 90 degrees;

- proceed with caution if the cable material is aluminum;

- strip the insulation for the connection to a segment equal to 3-4 cm;

- lay two cables on top of each other 1.5-2 cm above the bare spot at an angle of 45 degrees;

- holding the area above the cut with your left hand, start twisting the veins;

- work so that first there is a twist with insulation, and then a bare section;

- finish the twisting process with pliers for extra density.

The finished twist does not need to be covered with insulation immediately. The line should run for 2-3 hours. After that, you need to turn off the machine at the input and check the node temperature. Heating indicates the unreliability of the fastening - it will need to be redone. In the absence of heating, the conductors can be insulated.

Wire twisting tools

To properly twist the wires together, you will need:

- office or kitchen knife;

- nippers or side cutters;

- stripper;

- hydraulic or manual crimper;

- soldering iron - for stripping insulation;

- heat shrink tube;

- construction hair dryer;

- screwdriver.

An electric burner can be used instead of a soldering iron.

Operating procedure

The step-by-step twisting algorithm can be considered using the example of the interlacing of a stranded and mono-stranded cord. In this case, it is better to work in the branching technique:

- Stripping the area from the end of the conductors - 3-4 cm long with a stripper or a clerical knife.

- Placement of heat shrinkage on one of the cables.

- Degreasing of non-insulated sections with a special agent.

- Bend the single strand end 180 degrees to further press the strand.

- Wrap a stranded cord over a single strand. It will take 5-6 turns clockwise.

- Gripping the bent single-strand tip with pliers and pressing it against the joint.

- Placement of heat shrinkage in place of twisting and fixing it with a construction hair dryer.

The heat shrink should fix the twist tightly.

Connection isolation means

The resulting node must be insulated with high quality. For this purpose, three technologies are used.

Insulating tape

The adhesive backed tape is made of polyester and epoxy film, glass cloth and mica, acetate material and paper. For insulation of a household power supply, a tape with a class P PVC film and a rubber adhesive side is suitable. The material has good adhesion, elasticity and density. Closing the twist with electrical tape is carried out step by step:

- Winding starts 2-3 cm above the bare area, over the wire insulation.

- The tape is wound at a slight angle towards the end of the strand.

- In place of the tip, the material is folded around it and wound in the opposite direction.

- After the place of winding, the tape is trimmed with a clerical knife or scissors.

A two-layer coating with insulating tape will provide reliability and maximum tightness of the contact connection.

Electrical tape is suitable for twisting electrical cords in dry rooms.

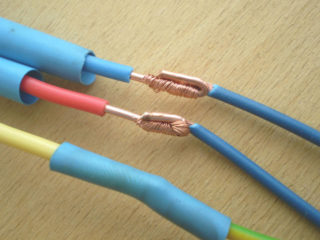

Heat shrink tubing

The thermotube is made from special polymers, which, when blown with hot air or from the action of warm water, shrink and expand. The heat-shrinkable material can be placed over objects with complex relief. When working with twisted conductors, the products provide high-quality insulation and protect against breaks.

The isolation process is carried out as follows:

- A piece is cut from the tube, 1 cm larger than the bare area.

- A piece is put on 1 wire before the start of the seam.

- The cable is being twisted.

- After twisting the cores, the thermotube is pulled over the twisting place.

- The tube is heated with a construction hairdryer or lighter at a distance of 1-2 cm. Under the heat stream, it will decrease and press firmly against the site.

Conductors insulated with a thermal tube, according to GOST, are allowed to be laid in a bathroom, immersed in soil or water.

Construction insulating clamp

When organizing home or apartment wiring, it is advisable to use special PPE caps. The products are put in place for insulation after twisting. The tip of the cap is cut off, and the PPE itself is forced onto the wire. Special springs on the surface will move apart and grip the connection tightly.For added strength, you can turn the cap clockwise.

When using PPE, the twisted section does not need to be soldered.

Professional recommendations

Experienced electricians give some advice on how to apply twist and consider all the risks of such a connection.

PUE allows

Standards cannot completely prohibit twisting. It can be used in combination with technologies:

- welding: twisted wires are additionally soldered to ensure the continuity of the contact;

- soldering: solders cannot provide mechanical strength to the joint. For this reason, the conductors are twisted, soldered, insulated and placed in a distribution box.

Use screw terminal blocks for extra density on the stranded cores.

Connecting conductors made of different materials

It is forbidden to combine copper and aluminum in one twist. A galvanic pair arises between them, which under the influence of moisture and chemical processes undergoes electrolysis. The resistance of broken contacts increases and then disappears. As a result, the seam heats up and burns.

The difference in the coefficients of thermal expansion of the material will lead to a weakening of the joint after cooling. Resistance starts to build up more intensely.

The appearance of an oxide film

Aluminum is a material on the surface of which an oxide film always appears. It increases the protection of the cable, but at the same time increases the contact resistance. To exclude it, the veins are covered with quartz-vasilin paste or special terminal blocks with this filler are purchased.

Twisting, as a type of connection of conductive conductors, is allowed to be used only as a temporary measure. In conditions of constant operation, the seam can lead to a fire in the wiring, fire hazardous situations.