In the houses of the old construction, aluminum wiring was installed. It has many disadvantages compared to copper and requires replacement. But the tenants of the apartments do not always carry out major repairs and completely change the electrical wiring. It can be partially replaced. Creating a reliable contact requires compliance with certain nuances and conditions, which should be familiarized with before repair work.

- Why it is impossible to connect copper and aluminum in electrical wiring

- Basic connection methods

- Twisting

- Soldering

- Crimping

- Threaded fixation

- Application of rivets

- Contact with two steel strips

- Terminal blocks, terminal blocks

- Spring-loaded and self-clamping terminal blocks

- Pads type "Nut"

- Features of the connection on the street

- Specialist recommendations

Why it is impossible to connect copper and aluminum in electrical wiring

Aluminum electrical wiring performed all its functions in old houses. Previously, electronic devices did not require much power. But with the development of technology, the load on wires and sockets began to increase, which made it necessary to look for new materials that could work under high voltage. This leads to the fact that it may be necessary to extend the aluminum cable with copper.

It is not possible to connect aluminum and copper wires directly. First of all, the incompatibility is associated with the properties of aluminum. It oxidizes and breaks down faster. When combined with copper, the destruction process is faster. Heating occurs due to the fact that the resistivity of aluminum is higher than that of copper. Also, aluminum is softer and has less electrical conductivity.

Copper and aluminum are galvanically incompatible. When touched, a chemical electrolysis reaction occurs, which impairs contact. The connection point is oxidized or heated, the insulation layer is destroyed, which increases the risk of a short circuit or fire. The process is accelerated in high humidity conditions.

Basic connection methods

To make the correct reliable contact between two different materials, special devices are used. They can be divided into two categories by the presence of contact between stranded wires:

- There is direct contact. Achieved by such methods as twisting, crimping, soldering.

- There is no direct contact. It is carried out using terminal blocks and threaded fixation.

To connect an aluminum wire to a copper one, it is better to use the second option. The first method can only be implemented if the copper conductors are pre-processed.

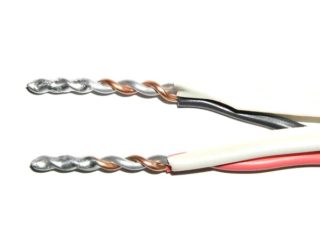

Twisting

This method is used in a domestic environment for a short time. Twisting the cables is unreliable, heats up quickly and breaks down. According to the requirements of the PUE, it is prohibited to use twisting in electrical wiring, especially when connecting two different materials.

Soldering

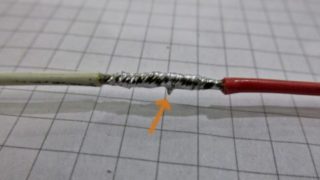

Two wires of different materials can be soldered together. But the wires need to be soldered only if the technological features of each material are observed. Copper and aluminum must be prepared for soldering. Difficulties can arise with aluminum conductors. A thin oxide film forms on its surface, due to which the solder does not stick to the wires. It can be neutralized with a special device.

The end of the wire is stripped and processed with copper sulfate in the form of a solution. Next, you need a battery. A conductor is attached to the minus.The copper is set to positive, the other end of the copper to the solution. After a while, a plaque will appear on the aluminum cable, which will allow the solder to fix on the electrical wire. After that, you can start to solder.

Crimping

When crimping wires, a sleeve or a tip made of plastic or metal is put on the connection point. The sleeve and tip allow you to fix and strengthen the contact between the cores. Externally, the sleeve is an insulated tube. The ferrule is usually made in the form of a plastic cap, into which the wires to be connected are passed. After threading the cables, the nozzle or sleeve must be squeezed with press pliers.

Clamping ring or cone spring attachments are available. They are put on twisted wires and crimped with pliers. With the help of such crimping, you can twist at home. The metal ring inside securely fixes the contact between the conductors.

Threaded fixation

The contact created by means of a threaded connection is reliable and stable. The cores are clamped together with a threaded nut. A washer is installed between the ends to prevent direct contact between copper and aluminum.

The main advantage of this method is its simplicity and versatility. The downside is the bulkiness and inconvenience of isolation. Thanks to the threaded connection, wires with different cross-sectional areas can be connected.

Algorithm for creating a contact:

- Strip the wires from the insulating layer by 1-1.5 cm.

- Create a ring of bare cores with a diameter larger than the bolt.

- Put the rings on the bolt.

- Place a spring washer between the wires.

- The connection must be secured by tightening the nut or using a rivet.

This wiring method is great for extending a wire of sufficient length.

Application of rivets

A rivet is a device that consists of a tube and a core. Fixed with a rivet. To create a contact, the cores, as in the case of a threaded connection, are stripped and laid out in the form of a ring. These rings must be put on a tube with a steel gasket - a washer. Then you need to squeeze the rivet, the core will squeeze the metal together and fix the cables to each other.

This contact is permanent. Its advantages are reliability, strength and durability. The difficulty of the work lies in finding a riveter; skills are also required to work with him. Used for electrical connection of conductors in hard-to-reach places.

Contact with two steel strips

Copper and aluminum can be connected by a simple method, which requires a preliminary tinning of the copper core. The wire is clamped by two steel strips with bolts at the edges. Advantages include the ability to connect multiple strands without increasing the bolt length. Bare parts are fixed between the planks. To use this method, you must take cables of the same diameter. The wires must be insulated.

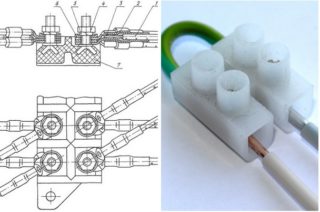

Terminal blocks, terminal blocks

A high-quality and reliable connection can be made using terminals and terminal blocks. They are a strip made of insulating material with connectors for installing wires. Clamping is carried out using bolts. There is no direct contact between the cores.

A terminal box is a system of several terminal blocks. They are combined into one structure and have several outputs.

Advantages:

- Ease of installation.

- High isolation reliability. There is no need to further isolate the system.

- 1-2 cm of cable is enough for secure fixation.

In the case of hidden wiring, it is required to install a junction box and an automatic machine at the input. There are also special flush-mounted terminal boxes on sale.

All wire ends must be securely fixed inside the terminal block.It is especially important to securely fasten aluminum conductors or when installing cables outdoors or in a room with high humidity and temperature.

Spring-loaded and self-clamping terminal blocks

On sale you can find disposable and reusable strips and terminal blocks. Spring devices securely fix the conductors with a spring, which, if necessary, can be loosened when installing or pulling out the wire. When the lever is lowered, the copper and aluminum will be securely fixed inside the terminal block. Disposable devices grip the cables when they are inserted into the socket; physical effort is required to pull them out. As a result, the spring mechanism can be damaged, and reuse becomes impossible.

The range of disposable and reusable terminal blocks is wide. They differ in the number of wiring branches to be connected, the cross-section of the wire to be installed. The use of terminal blocks is one of the most popular and convenient ways to create contact between wires.

The first self-clamping terminal blocks were manufactured by Wago. They create and sell connectors of the same name. You can find many analogues on the market, including those produced by unknown companies. Such devices can be unreliable, therefore it is recommended to buy all electrical appliances from specialized stores.

Wago self-clamping terminal block connection algorithm:

- Remove the insulating layer from the wires by about 0.5-1 cm.

- Install the stripped part of the conductor into the corresponding socket of the terminal block.

- Fix the wire with a spring clip or screw.

Additional insulation of the connection point is not required. The disadvantages of connecting with Wago pads is the high cost of products.

Pads type "Nut"

There is another type of terminal block used to contact two conductors. These are “Nut” terminal blocks, which are two copper plates enclosed in a plastic case. They are used for branching cables of large diameter, as well as for use in outdoor conditions.

The mechanism is simple. Veins are laid between the two plates. Then they need to be pulled together with bolts. For insulation, a protective plastic case is put on top, which consists of two halves that look like a nut. The halves are also fastened using standard screws.

Features of the connection on the street

All wires and cables laid outdoors are negatively affected by external factors. Snow, rain, high temperatures, direct sunlight may disrupt the connection. Therefore, the connector must be highly resistant to all negative factors and hermetically seal the contact point. In open areas, piercing clips are used to create contact.

Specialist recommendations

To safely connect copper and aluminum conductors, you should use the following rules:

- If the connection will be carried out by soldering or welding, the copper must first be tinned. For aluminum, special solder is required.

- It is not recommended to apply strong pressure to the contact points and to allow mechanical impact on them. This can lead to deformation and damage to the wires.

- The marking must be observed.

- Terminal blocks and other connectors are selected taking into account the operating conditions. For outdoor use, the device must have a high degree of protection against moisture, ultraviolet rays, and high temperatures. Also, the terminal block must be selected taking into account the cable cross-section.

Do not twist wires to electrical wiring. This is an unreliable method in which materials are heated, destroyed, which can lead to fire.

To improve the quality of contact, a special lubricant or paste can be used.Most often, quartz-vaseline paste or another agent that repels moisture is used. It improves the connection of the aluminum electric wire. It is used in all types of connections. It is especially recommended to use the paste outdoors. It additionally protects contact and limits negative environmental influences, which increases durability.

It is rather difficult to put insulation on the paste. The insulating tape will hardly stick and the heat shrink tubing may be damaged. Therefore, you need to think in advance how the contact of the two conductors will be protected.

in the article - According to the requirements of the PUE, it is forbidden to use twisting in electrical wiring, especially when connecting two different materials. “Especially when joining two different materials” - does this mean that twisting of the same materials is still possible?

Twisting the same materials is not only possible, but also required! Twisting of wires is done in special junction (junction) boxes. If the boxes are maintenance-free, that is, they are located behind a stretch ceiling or behind a plasterboard ceiling, then the twists are also soldered or boiled.