Soldering wires is a mandatory set of measures, the task of which is to install electrical wiring in the room. High-quality connection of cores by soldering, connection of wires in the switchboard, correct twisting are factors on which the durability and performance of electrical wiring depends.

Advantages and Disadvantages of Soldering Electrical Wiring

To properly solder the wires, you need to familiarize yourself with the advantages and disadvantages of the method. Despite the existing analogues, this method is considered the most widespread and demanded, especially in electronics.

Advantages:

- Reliability. An important parameter is the presence and magnitude of the transient resistance. The lower it is, the better. For soldering, this parameter is extremely small. In terms of reliability, soldering is inferior to welding only in one case - if the work had to be performed under extreme conditions, for example, in an environment with extremely high or low temperatures, exposure to aggressive media. If we are talking about apartment wiring or a country house, such factors are excluded.

- The connection is maintenance-free.

- Versatility of use. With the help of soldering, it is possible to connect single-core and stranded wires with different cross-sectional areas, in any combination. This versatility allows you to solve many non-standard and difficult tasks. In addition, the use of fluxes provides a reliable connection between copper and aluminum conductors.

- Low connection cost. To carry out the work, you will need a soldering iron, solder and flux. The cost is low and the consumption is economical.

Disadvantages:

- Low manufacturability. To carry out the work, many preparatory measures are required, hence the high labor intensity.

- The need for the qualifications of the performer.

When soldering, changes in matter occur at the molecular level, so the pre-soldered parts are thoroughly prepared.

What you need to solder electrical wiring

Before soldering the wire, prepare a working tool and consumables. To complete the work, you will need the following list of tools:

- An ordinary household soldering iron, the power of which ranges from 40-100 watts. As an analogue, a welding machine is used, on which it is possible to control the temperature of the tip, which simplifies the soldering process.

- Small file for cleaning the soldering iron tip.

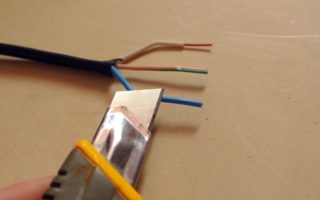

- Knife for removing the insulating layer.

- Twisting pliers.

- Rosin intended for surface tinning.

- Solder for soldering different materials, acid-free fluxes are used as an analogue.

Soldering of aluminum and copper wires differs somewhat in the types of solders used.

| Copper | Aluminum |

Tin and lead compounds are used. The marking is as follows:

|

|

How to properly solder the wires

The soldering process may vary slightly depending on the materials used. Different methods involve the use of different solder compositions and fluxes.Most often, the soldering of wires is carried out when connecting copper wires with a cross-sectional area of up to 6 mm sq.

When performing work, the following algorithm is observed:

- An insulating layer with an approximate length of 5-6 cm is removed from the wires.

- The working tool is heated and the surface is covered with a layer of rosin or flux. The first does not work well on oxidized surfaces; with deep penetration into the twist, it is important to carefully pre-process the materials.

- When heating the wire with a heated tool with solder on the tip, it is important to achieve an even distribution of the solder over the entire surface to be treated.

- When soldering strands, specialists must fill in all irregularities with solder.

- At the end of the work, all twists are carefully insulated using special nozzles, electrical tape and heat shrink tubing.

When working with aluminum, it is important to take into account its high oxidation rate when in contact with oxygen. The resulting film does not allow creating a reliable adhesion of the metal to the solder.

The oxide is removed mechanically, then the surface is serviced. The algorithm for connecting aluminum conductors depends on the type of flux used and the cross-sectional area. For heating, as a rule, a gas burner is used.

The procedure for soldering lived with an area of 4-10 mm.kv:

- An insulating layer is removed at the ends of the cores 5-6 cm long.

- To obtain a metallic sheen, the veins are cleaned with a file, emery paper or a knife.

- The conductors are overlapped with each other using the double twisting method; a groove is made at the point of contact in the middle.

- The junction is heated to a temperature that is close to the melting point of the adhesion.

- Each side of the twist is processed in a similar way, all cavities are filled with tin.

- At the end of the work, the junction is cleaned with gasoline.

- The cleaned surface is covered with asphalt varnish and carefully insulated.

The work is not fast, but the high quality and durability of the connections is worth the time and effort.

How to solder copper and aluminum wires

The copper wire is carefully stripped, then immersed in rosin. The specialist melts a few drops of solder and for tinning the wire is immersed in the molten mass. The procedure is performed with gentle and even movements.

The solder should cover the surface of the wire as little as possible. The excess is removed with a hot soldering iron. During the course of work, the red tint of the copper wire should change to silver.

If work is to be done with stranded soldering irons, each wire must be untwisted and only then tinned. Then everything returns to its original position.

Before soldering electrical wires, the aluminum wire must be stripped, after which the previously prepared flux must be evenly distributed over its surface. Next, the aluminum wire is carefully rubbed with a small piece of oil and grease and heated by the flame of a gas burner. Such manipulations will effectively get rid of the oxide film.

To increase the quality indicator of the connection of single-wire wires, twisting from tinned wires of small sizes is used. All formed cavities are filled with tinol.

The next step is to connect copper and aluminum wires. For this, the insulating layer is restored. For dry rooms, use only cotton tape.

Recommendations, precautions

You should familiarize yourself with the recommendations that will allow you to perform the assigned tasks with high quality:

- When choosing a soldering iron, you need to pay attention to models that are additionally equipped with cones, needles and a set of replaceable tips.

- Before proceeding with soldering, you need to pay special attention to stripping the tip.If the tip is too dirty, remove all the dirt with a soldering iron. You can use pieces of wood or cardboard as an aid.

- Changing the length of the soldering iron also changes the heating temperature of the tool.

- It is not recommended to leave the soldering iron "dry" during the heating of the working element. It is necessary to regularly dip the sting in rosin.

It is important to take precautions. You need to work in personal protective equipment: special clothing (overalls), glasses and gloves. Do not leave open areas of the body, otherwise severe burns may occur.