When arranging underground power supply lines, implying difficult operating conditions, armored cables of the AVBbShv type are traditionally used in electrical engineering. Their distinctive feature is the presence of a protective shell consisting of lead, which is called armor. A prerequisite for their safe operation is the grounding of the armored cable, organized according to standard rules. For these purposes, both station and repeated grounding devices (ZU) are used, which are equipped on the consumer's side.

What needs to be grounded

When wiring armored cable lines, the following parts of structures and braiding elements are subject to mandatory grounding:

- armor and shield of power and control cables;

- special couplings;

- elements of metal products used for laying: trays, boxes and similar structures;

- metal pipes used for the same purpose;

- special suspension cables for aerial laying of power lines.

According to the requirements of the PUE, each of the ends of the cable line, separated by significant distances, is relied on to ground. The regulations specifically state that sections of electrical lines longer than 200 meters are subject to re-grounding.

Basic grounding rules

The PUE pays special attention to the grounding of the cable armor on both sides, since only in this case it is possible to be sure of its absolute reliability. When organizing such work, the following details are taken into account:

- for grounding the armor of cable products, flexible copper-based conductors, devoid of insulation, are used;

- no breaks in the continuous coating are allowed throughout the gasket, it must be solid;

- when restoring a damaged line, the sheaths of individual sections and the coupling must be connected with flexible conductors.

But first, these parts should be carefully prepared for installation work.

Grounding instructions

When grounding an armored cable, PUE is recommended to act in compliance with the following rules:

- The grounding conductor is soldered to the cable armor.

- First, this place is carefully tinned, after which a grounding conductor is soldered to it with the help of a wire bandage, with the obligatory use of soldering grease.

- To connect a copper tap without soldering, special clamps are used.

For these purposes, it is also allowed to use spring-loaded connectors that guarantee reliable contact with the protective layer.

In the case of tape armor, the ground wire is attached directly to its taps, and in the case of wire braiding, in a circle to all its veins. When connecting cable lengths of standard length, sealed couplings of a special design are used. The set of connectors includes:

- local elements of waterproofing;

- tips with special bolts;

- a ground wire fixed to the armor of the sections to be connected;

- clamps for fastening a wire with armor made of wire or steel strips.

When cutting the cable, before arranging the contact, the upper insulating layer is removed to a length slightly larger than the braid located under it.In certain types of couplings, the manufacturer provides a special template that guarantees high-quality cutting of the entire product.

Grounding inside a private house

According to the PUE, when grounding the cable armor in a domestic environment, the following rules must be observed:

- armored cable 0.4 kV is allowed to be laid in metal structures, reliably grounded and available for repair and maintenance;

- laying on concrete floors and wooden flooring is made with a gap of at least 5 cm; for this, metal boxes and special supports are used;

- it is allowed to enter the house both through the floors and through a specially designated area of the wall.

In order to prevent damage at the entrance to the structure at the points of wiring through walls or foundation foundations, the cable is laid in a metal or plastic pipe.

The diameter of the pipe segment is chosen 2 times larger than the cross-section of the cable product itself.

When the line is introduced into the house, the armor is grounded in the switchboard, as well as from the side of the branch support. According to the PUE, no other connections on this section of the route are allowed. At the input, the cable is cut into several cores that are connected to the switching devices; at the same time, his armor is necessarily connected to the grounded point of the shield body - directly to the ground.

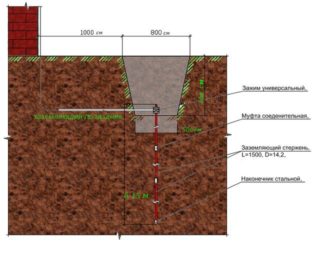

Grounding an underground cable

To obtain high-quality grounding of the cable screen, PUE recommend adhering to the following rules:

- The cable armor and protective structures (structures) used for their laying should be connected to elements of grounding electrodes of any type.

- The connection is formed due to reliable contact with the bare parts of metal pipes, reinforcing rods and other elements of natural grounding conductors.

- When organizing a power supply network in a private house, the armor of the introduced underground cable VbBShv is connected to the re-grounding device.

When wiring control and optical cables, grounding of at least one of their ends is considered mandatory.

For signal communication lines, grounding is done in order to reduce the effect of electromagnetic fields on the transmitted data streams or to completely eliminate it. For especially important areas of information exchange, a two-way ground fault is arranged. The screen of such cables is connected to the GZSh of the junction boxes by means of copper conductors with a cross section of at least 4 sq. millimeters.

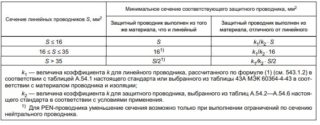

Requirements for conductors

When installing grounding, as well as protective grounding, steel sheaths of cables of any class or armor is connected to the charger by means of copper conductors of a standardized cross-section. This requirement also applies to couplings or end couplings. On lines designed for the transmission of high-voltage power supply (6 kV and above) and having an aluminum sheath, the coupling grounding is performed by separate conductors.

It is prohibited to use copper conductors with a conductivity greater than the corresponding indicator for cable sheaths for this.

The general requirements of the current standards provide for the use of bare copper conductors with a cross section of at least 6 mm square. The same parameters for control cables are specially specified in the PUE (see p. 1.7.76-1.7.78).

If end couplings are provided on the support of the air supply to the electrical installation, containing arresters in their set, their cases are connected directly to the memory of the protective devices. The use of cable sheaths alone in this capacity is not allowed in this situation. Special overpasses and galleries used for placing cables in an explosive design must be equipped with protection against lightning discharges and lightning.

When moving from the underground laying line to the section of its overhead wiring and if the reinforced concrete support does not have its own memory, the coupling is allowed to be grounded to the cable armor. This approach is permissible only if the repair or extension sleeve at its other end is connected to the station grounding loop, or if the resistance value of the sheath of the grounded cable is sufficiently small.

When laying underground utilities based on armored cable products, the efficiency of their operation largely depends on the quality of the protective sheath grounding. When carrying out electrical work of any level of complexity, increased attention is paid to this issue.