A relay is a device designed to control high power signals with low power signals. Its main task is to separate and protect the low voltage circuit with an electromagnetic coil from the high voltage circuit. There are several ways to make sure that the relay is working, the most convenient, fast and reliable is to use a multimeter.

- Design and principle of operation of the switching device

- Principle of operation

- Types and characteristics

- Malfunction symptoms

- Reasons for the failure of the relay regulator

- Preparing to test the relay for operability

- Diagnostics of the winding and contact groups

- Abnormal voltage readings on the multimeter

Design and principle of operation of the switching device

An electrical relay is a part that is used as a switch due to the control signals that come to it through an electrical circuit. The line connected to the device is called controlled; the line through which the command is already coming to him is the control one.

It is used in domestic conditions and in all industries in order to automate various operations. If a household or electrical appliance is out of order, it is required first of all to check the functionality of the switching element. But first, it is recommended that you familiarize yourself with the types and principle of operation of the relay.

Principle of operation

The armature is located on top of the core of the magnetic system; in the initial position, it is held by a spring, which has the shape of an L-shaped movable plate.

The lower part of the base is equipped with a contact group, opposite the same number of contact bases. The contacts are plastic, since they need to be brought out outside the protective case to form a device terminal.

The principle of operation of the relay is based on its ability to influence conductive objects with its own electromagnetic field. As soon as voltage is applied to the winding terminals, current begins to flow through the relay. When its value reaches the previously programmed value, two forces are generated in the winding, which press the armature against the surface of the coil.

Taking into account the design features, the initial position can be not only closed, but also open. In the second case, when voltage is applied, the line will open. The contacts of the device will return to their original state as soon as the signal of the required value is removed from the relay outputs.

Types and characteristics

Depending on the used element base, relay-regulators are divided into the following types:

- Microcontroller or microprocessor based. Their peculiarity lies in the fact that a working algorithm is embedded in the built-in microcircuit. They are used in expensive cars such as BMW or Audi.

- Relay based on switching relay contacts to cut off and stabilize the indicators of the electrical network.

- Integral relays are widely used in the automotive industry. The principle of operation is based on solid state switching parts or integral semiconductor parts.

- Hybrid transistor-relay devices and simply transistor ones are based on semiconductor elements. They were actively used in industry until the early 90s.

By design, they are divided into the following types:

- External relays are separate devices that are installed on body structures.

- Built-in switching parts are an integral part of the generators.

- Combined or hybrid. Their peculiarity lies in being combined with the brush assembly of an electric generator.

The electrical relay can be two-, three- and multi-level, divided by "+" and "-".

Malfunction symptoms

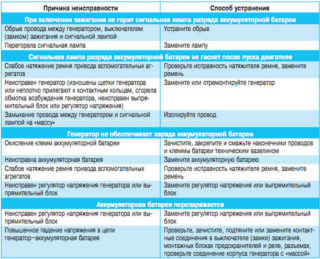

Before you check the relay with a multimeter, you should familiarize yourself with the main signs that the part is out of order.

- There are cases when, as a result of the failure of the voltage regulator, the battery boils.

- On the dashboard, when the ignition is turned on, the control lamp does not light up (however, this can be a symptom of other types of malfunctions, for example, a contact has disappeared or burned out).

- The dynamic characteristics of a household appliance or car are reduced, especially when the engine revs up.

- After starting, the battery indicator does not go out on the dashboard, which indicates a battery malfunction.

- The indicators on the dashboard simply turn off if the engine speed during operation exceeds 2000 rpm.

- The brightness of the headlights depends on the engine speed. It is quite simple to make sure of this - you need to stand against the wall in the dark and turn on the headlights. The brightness of the glow will change depending on how hard you press on the gas.

- The battery is discharged regularly.

These signs may indicate other malfunctions, but first of all, it is recommended to check the relay-regulator.

Reasons for the failure of the relay regulator

- Short circuit on any part of the electrical circuit, including the interturn short circuit of the field winding.

- The regulator can also fail in case of diode breakdown or breakdown of the rectifier bridge.

- Incorrect connection or reverse polarity to the battery terminals.

- Penetration of moisture or a large amount of dust into the generator and / or the regulator itself (such cases are common during heavy rainfall or car wash).

- Mechanical damage to the working unit.

- Natural wear and tear, end of service life.

- Initially questionable quality of the purchased product.

There are several simple ways to ring the built-in and plug-in relays.

Preparing to test the relay for operability

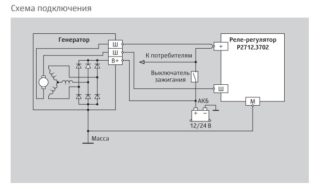

Before proceeding with the diagnostics of the device, it is necessary to determine the purpose of the pins of the checked part. To do this, use the attached documentation to the device, it contains all the diagrams and features of operation, the characteristics of the device.

Cases are common when the operation diagram is depicted on the relay body itself. The dots represent the contacts, they are connected by an inductance coil, the switching elements are straight lines with a dotted line. The power supply pins are schematically shown as a rectangle.

If the relay is built into the circuit, on the board itself, it is required to visually inspect the condition of the bus and the power track. To test the relay with a tester, you can use both digital and analog devices. No preliminary preparation and setup of testers is required.

In addition to the tester, it is necessary to prepare an adjustable power supply. For the results to be reliable, the relay must be removed from the circuit.

The operability check is carried out in several stages:

- winding;

- normally closed position;

- normally open state.

Then you can proceed directly to the relay diagnostics.

Diagnostics of the winding and contact groups

Diagnostics of the winding allows you to find out if its integrity is violated. The performance check is carried out in several stages:

- The multimeter is switched on in resistance dialing mode. On the instrument panel, this mode is indicated by the symbol - Ω, the range is set within 2 kOhm.

- One test lead is connected to the socket, and the second to the COM.

- The wire probes touch the relay terminals.

The resistance of the inductor can be recognized by the deflection of the arrow.

Contact groups are verified in two stages. First, the resistance is necessarily measured offline, and then when voltage is applied to the coil. When checking, you will need a power source, you need to take care of this in advance.

Abnormal voltage readings on the multimeter

If the multimeter shows a low voltage in the battery, the battery will simply stop taking charge. As a result, the car may not start, the indicators on the dashboard may stop working, and troubles may arise while driving.

If the voltage is increased, it is likely that the electrolyte level in the battery bank has decreased, or it has simply boiled away. Also, a characteristic feature may be the formation of white plaque on the walls of the body. When recharging, the battery may behave unpredictably.