Most of modern technology is powered by the mains. Connections require wires that can get tangled with each other and get damaged. To prevent the cables from getting tangled, ties are used to fix them in one bundle. Before you buy clamps for wires with fasteners, you should understand their varieties.

Requirements for cable ties and their types

A number of requirements are imposed on cable ties that must be observed for high-quality and long-term performance:

- high strength of the clamp;

- long service life of the wire tie;

- fixation reliability;

- keeping the bundle of cables in a strapped state for a long time;

- fire resistance;

- resistance to external negative factors;

- wide range of operating temperatures.

In hardware stores, you can buy screeds of various shapes (strips, spiral), lengths and made from different materials. The width is usually a few mm. Also, products are classified according to the type of locking system.

Material classification

Depending on the material of manufacture, screeds are divided into the following categories:

- Plastic. They are made of two types - polyamide and polyethylene. They have a wide range of operating temperatures - from -40 ° to + 80 °. Plastic cable ties for securing wiring are inexpensive and easy to work with as they are soft and flexible. The disadvantages include the unreliability of the lock connection and the complexity of installation due to the plasticity of the material. For indoor use only, outdoor use is prohibited.

- Metallic. They are made of stainless steel, there are also models with an additional PVC coating. These are the most tear-resistant electrical wiring clamps. They can operate at temperatures from -80 ° to + 500 °. Non-flammable, can be used outdoors. The disadvantage is the high cost.

Plastic screeds with charcoal supplement can be used outdoors. The addition of carbon makes them more UV resistant.

Reusable classification

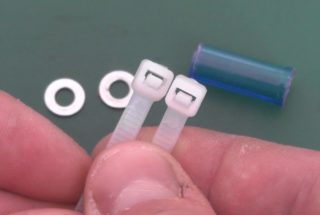

The most common on the market are disposable bandages with one-way travel and one-piece lock. But you can also purchase a versatile reusable product. Such cable clamps have two lugs, thanks to which the bands can be connected into a chain of the desired length. Such screeds have found their application not only in electrical work, but also in households. With their help, you can shorten the cables, fix the unnecessary part, and fasten them to the wall. Thanks to the fasteners, the workplace will always be neat, and the wires will not get in the way under your feet.

Reusable products include Velcro straps. They allow you to quickly and easily fix the wire and add new harnesses. Made of nylon or polyethylene. Usually, plastic objects are attached with such ties.

Electric ties are used not only for connecting cables into a bundle, but also for marking bundles or wires. For this, colored products are used. Also, a small area can be applied on the screeds, on which you can leave inscriptions about the purpose of the beam. The pad looks like a wrapper or checkbox.

Types of locks for screeds

In addition to the classification by material, screeds can be divided according to the type of locking system. Types of locks on sale:

- standard;

- with a metal tooth;

- ball;

- reinforced.

Each of the types has its own principle of action.

Standard lock

It is a strip made of plastic or metal. The strip has sawtooth projections on the inner side. There is a lock on one edge of the tie, which looks like a small box with a retainer installed in it. The locking mechanism also features sawtooth protrusions that prevent the clamp from opening.

The cable clamp must be wrapped around the cable group. The free end is held in the lock in a special slot. Next, the tie must be tightened. There is no reverse motion in bandages of this type.

Metal tooth lock

On the inside of the lock, a metal plate or tooth is mounted on a plastic band. Usually made of stainless steel. The tooth should be set at a 45 ° angle to the strip. Sharpening must also be applied. When pulling the cables, the strip can move freely in the lock; when you try to pull it back, the tooth will block it. Tightening should be done smoothly in order to more accurately and reliably pull the wires.

Ball lock

These types of locking mechanisms are used in metal bands. The lock is a metal case in the form of a cone, in which a metal ball is located. During tightening, the ball is pushed into the wide part, when trying to pull the strip back, the ball goes into a narrow area and blocks it.

Reinforced clamp lock

Such systems have sawtooth projections that are located on the outside of the nylon band. The lock has large teeth.

Reinforced clamps can be produced with single and double locks.

Wire bundling guidelines

For long-term operation, do not tighten the screeds too much. It can also damage the wires.

If you plan to add new and remove old wires, reusable cable ties should be preferred.

For the street, you need to select bandages that are resistant to ultraviolet radiation, moisture and other atmospheric precipitation.