LED strip is convenient for creating any kind of lighting and the embodiment of design ideas. It is a flexible printed circuit board with LEDs and resistors attached to it. You can install the LED strip yourself.

Basics of mounting LED strips

When starting to install duralight, you need to remember the basic rules and features of its fastening:

- There is an adhesive layer on the reverse side, but you can only glue the duralight once. The surface must be dry, level and solvent-free for the tape to hold firmly.

- The board does not tolerate bends well. The maximum bending radius is up to 5 cm.

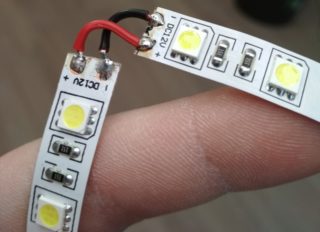

- You can cut the board only along the marks - usually every 3 diodes.

- Duralight is connected by soldering or using connectors. Soldering time - 1 sec. The soldering iron is heated to a temperature of no more than 260 degrees.

LED lighting is mounted in the kitchen, in niches, combined with a stretch ceiling or plasterboard structures.

Advantages and disadvantages of LED lighting

- Low power consumption when compared to other light sources.

- Long service life: if you follow the rules of operation, the duralight will last much longer than other lighting fixtures.

- Easy and simple installation: thanks to the self-adhesive layer, the fastening of the tape is quick and quite reliable. It can be cut, connected with a soldering iron.

- Safety. Unlike many lighting fixtures, LEDs do not get very hot, and thanks to their installation in a profile, they can be combined with materials that are susceptible to high temperatures, for example, PVC canvas, from which stretch ceiling structures are made.

- The ability to change the color of the backlight. The shade of the glow is changed using the controller.

The main advantage of the tape is its versatility. It can be connected not only to a 220 V network, but also to a car battery.

An important disadvantage of duralight lies in the weak intensity of the light flux. Therefore, the backlight is used as decorative and additional lighting.

Recommendations for installation and use

The success of installing an LED strip during do-it-yourself installation depends on compliance with the rules for storage and connection. Here are some tips:

- It is forbidden to exert excessive pressure on the board and bend it too much, as this will damage the conductive tracks.

- For connection, you must use connectors and connectors that correspond to the marking.

- Make connections carefully to avoid damage.

- To ensure proper ventilation of the diodes, the tape must be fixed to the aluminum profile.

- The level of moisture protection is taken into account. It is designated by the letters IP.

- Duralight and components require periodic maintenance, so they must be freely accessible.

Professionals do not recommend making LED backlighting when installing glossy stretch ceilings, because LEDs are reflected in the canvas, like in a mirror, which makes them too noticeable.

What you need to install

No complicated tools or fixtures are required for installation. A soldering iron is used to connect the tape, but it is also optional. Components required for the installation of a low-voltage LED strip: controller, power supply, connectors.

Controller

This device is designed to adjust the glow mode of the diodes and change the color of the backlight. By connecting the controller, using the remote control, you can make the LEDs flash or sparkle in different colors. For a single-color duralight, a controller is not needed. Before buying, you need to clarify how many soldering contacts the tape has in order to purchase a suitable device.

Power Supply

For the correct and long-term operation of the duralight, a power supply is required. It lowers the mains voltage. The power of the unit is selected in accordance with the LED strip - a stock is needed. Connect in front of the controller.

If the tape is 220 V, instead of the power supply, you will need a rectifier - a diode bridge.

Connectors

The connectors allow you to connect separate parts of the tape without using a soldering iron. But first you need to choose a suitable connector: flat or round.

If desired, a dimmer is also used to adjust the level of light intensity, but it does not need to be used.

LED Strip Installation Guide

The basic rule of installation is that the segment should not be more than 5 meters long. It is necessary to connect each such segment in a parallel way. With sequential installation, the luminescence power will decrease.

You should not be afraid of electric shock when using a tape connected through a power supply. However, you need to remember about fire safety. Even low-voltage tape heats up to about 70 degrees. If you stick it directly to the wallpaper, the material may burst. A special aluminum or plastic profile will dissipate heat and protect the board and LEDs from mechanical damage.

- First, you need to separate a segment of the required length according to a special marking or, conversely, connect several segments using a soldering iron / connectors. It is more convenient to perform this operation on the floor, carefully controlling the quality of the joints.

- The finished tape, if it is colored, is connected to the controller. The controller has connectors that correspond to different colors. They are marked with letters: R-red, B-blue, G-green. RGB pins are negative. There is also contact - a common plus.

- The controller is connected to the power supply. In this case, the polarity is strictly observed.

- Check the functionality of the electrical circuit by plugging the system into a power outlet. If everything works, you can proceed to the installation in place.

- Installation is carried out according to the previously made markings. The power supply is placed in a niche or on a cabinet, providing ventilation, since it heats up during operation. If the tape is fixed to the adhesive layer, you do not need to completely remove the protective strip immediately. The strip is removed gradually as it adheres to the substrate. During installation in the profile, the tape is fixed with glue, and then a diffusing plinth is inserted into the profile, which will soften the light.

After installation, you need to check again if the backlight is working, since something could be damaged in the process.

Installation options

Install LED backlighting in a variety of places:

- ceiling;

- work surface in the kitchen;

- shelves in the bathroom;

- veranda;

- garage;

- bath;

- trunk and car interior.

The main rule is to connect through a power supply, which plays the role of a step-down transformer.

How to rotate an LED strip 90 degrees

Bending the tape with a radius of more than 5 cm should be avoided, so it cannot be simply folded if it needs to be fixed at a 90 degree angle. The board should be cut along the cutting line into two pieces, glue them together, and then restore the electrical contact.

One of the most convenient ways to connect when turning is the angle connector. It is made in the form of a corner element with latches at the ends or in the form of a connector with latches connected by wires. They can be 2, 4 and 5-pin. The former are used for single color strips, the latter for RGB, and the third for RGBW LED strips.

Before connecting the two segments, you should clean the contact pads along the edges with a knife, and then install them in the adapter. Such a system is easy to assemble and disassemble, even if it is in a hard-to-reach place. There is a drawback - the high cost of the connectors.

The second installation option will avoid costs. You will need wires according to the number of contacts and a soldering iron. The wires should be copper stranded with a cross section of 0.75-1 mm2. Installation instructions:

- The wires and contact pads are cleaned, tinned and connected with a soldering iron in accordance with the polarity.

- The flux is removed with a toothbrush moistened with alcohol.

- To prevent the connection from being exposed to moisture, protect it with hot glue or heat shrink tubing.

To use the heat shrink tubing, it must be slipped onto the tape before soldering.

This method of connection is cheap and reliable, but it will not work quickly to disassemble it.

To install the LED strip yourself, just follow the detailed instructions. LED lighting is versatile. The tape is often used to organize the lighting of a plasterboard or stretch ceiling, but this is not limited to its scope.