Dismantling of the socket is carried out in case of wear, breakdown, obsolescence and in the process of overhaul. In theory, this event should be carried out by specialists with education, experience and admission to hazardous work. But if you follow simple instructions and follow safety measures, you can do this procedure yourself, saving money and gaining much-needed skills in everyday life.

The principle of replacing sockets

Regardless of the type and location, the device of all outlets is approximately the same.

Overhead products consist of a decorative cover and a terminal block, in which the terminals and contacts are located. Mounting to the wall is done through the holes in the block. Outdoor structures are used when laying an electric line under drywall or in wooden buildings where the wires are laid in an open way. Removing an overhead outlet is not particularly difficult. It is enough to remove the cover, loosen the contacts and pull the wire out of them. After that, you can remove the shoe and install a new device.

With internal sockets, the situation is somewhat more complicated. Their pads are fixed in special sleeves, which are embedded in pre-prepared holes. The main difficulty lies in the correct replacement of the socket boxes and fixing new products in them.

- pliers;

- Screwdriver Set;

- a hammer;

- chisel;

- indicator;

- Head Torch;

- stationery knife;

- insulating tape;

- dielectric mat;

- protective glasses.

The main condition for work is safety. Before starting dismantling, you need to de-energize the room where the work is being done. If this possibility is not technically provided, you need to turn off the general packet switch or unscrew the plugs. In order to avoid emergency situations, hang a sign "Do not turn on, people are working!" On the dashboard. If the flap door does not close, for the period of work, one of the neighbors or relatives must always be near it.

After de-energizing the room, you need to make sure once again that no voltage is applied to the terminals. For this, an indicator or any serviceable household appliance is used - a table lamp, a razor, a fan.

Step-by-step instructions for dismantling

After checking the absence of voltage in the network, you can proceed to dismantling.

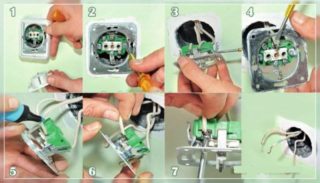

To disassemble the outlet, proceed in the following sequence:

- Remove the cover of the old socket. To do this, unscrew the bolt or screw located in the middle. If the cover is stuck to the wall, gently pry it off with a flat screwdriver.

- Once again we check the absence of voltage on the line. We put a dielectric rug under our feet, arm ourselves with goggles and a headlamp.

- We unscrew the bolts regulating the position of the legs. If they have become attached to the block, you need to slightly press on them with a screwdriver, after cutting the wallpaper.

- We take out the block from the glass, unscrew the wires from the contacts. If the threads on the bolts are corroded and won't give way, a little machine oil should be dripped onto the threads. If this does not help, the wire must be cut if there is sufficient supply for this.

- Disconnect the ground wire. If it goes to another device, you cannot cut it, as this will negatively affect the grounding parameters.

- We remove the old socket. The iron sleeve can be crushed with pliers, and the plastic one can be pulled out by the edges with pliers. In order not to pull out a piece of plaster, you need to make a groove around the sleeve with a knife or drill several holes.

- We clean the hole from crumbs and debris. We check the compliance of the new glass with the existing hole. If it is small, expand it with a hammer and chisel. You can use a diamond bit. The diameter and depth of the recess should be 4-8 mm larger than the glass. Again we clean the hole from debris and dust. It is advisable to close the bottom with felt to avoid the penetration of noise, bedbugs, fleas and cockroaches from neighboring apartments.

- We knead the starting putty, coat the socket with it, thread the wires through the hole and insert it into the niche. The product must be aligned so that its edges are in the same plane with the wall.

Before continuing to work, you need to wait 2 hours for the solution to set. After the putty has completely hardened, it is necessary to grout and polish the wall. Then you need to treat it with a deep penetration primer to strengthen the surface.

If you plan to replace the wiring, you should firmly fasten the old and new cable and pull the new wiring through the channels, using the old line as a pull rope.

Setting up a new connection point

After installing a new glass, you need to clean the ends of the wires from debris and dirt, check the integrity of the insulation. If there is damage, it is repaired with shims, electrical tape or heat shrink tubing. The veins must be cleaned of oxidation. It is advisable to solder copper wires, since over time they oxidize, the contact becomes worse and the socket begins to heat up, which is fraught with fire and fire.

Installation is carried out in the following sequence.

- We check the new product for integrity and completeness.

- We look at how tight the plug fits into the terminals. We make adjustments if necessary.

- We loosen the spreading legs, fix it with a clerical elastic band so that during the installation process they do not cling to the walls of the sleeve.

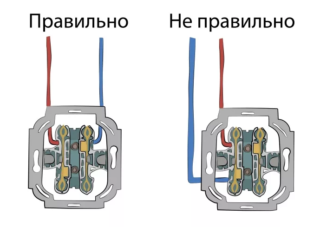

- We insert the wires into the contacts so that they protrude from the other end by 2-3 mm. You need to insert it on the left side of the bolt so that when it rotates, the wire does not push out of the socket.

- Tighten the bolt tight. It is desirable that it flatten a little when twisted. The quality of the tightening is checked by hand by tightening the core by hand.

- We fold the cable slack with an accordion, recessed the socket into the hole, controlling its correct horizontal position.

- When the bracket rested against the edges of the glass, we begin to twist the bolts of the legs. This must be done in turn, several turns, so that the product does not warp.

- Installing the cover. Some models have bolts, some are held by latches.

- We check the performance of the outlet using an indicator or any electrical device. The fastening strength is tested by inserting and removing the plug.

After that, you can turn on the packet switches or screw in the plugs.