Electrical work related to cables is accompanied by the need for repair, installation, maintenance. All of these processes use a variety of special devices, including clamps. They allow you to build up a wire if there are not enough meters or if you need to change a failed section. They are also used for temporary connection to testers, oscilloscopes and other instruments. There are a large number of types of clamps, each of which has its own characteristics, advantages and connection method.

- The most common types of electrical clamps

- Simple screw terminals

- Self-tightening and lever-operated clamping structures

- Connecting insulating clamps

- Piercing clamping mechanism

- Piercing mechanisms for self-supporting insulated wire

- Clamp between nut and bolt

- Clamps for other purposes

- Anchor type clamps for fastening

- Clips for test tasks

- Correct cable connection

The most common types of electrical clamps

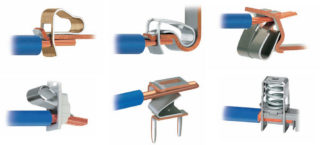

You can find a wide range of different clamps in electrical stores. They differ in material (metal, plastic, plastic), purpose, method of fixation, place of installation (street, room). It is impossible to describe all types, but there are a number of models that are used most often. The use of a particular type of clamping mechanism depends on the characteristics of the electrical network, connection parameters, operating conditions and other important criteria.

Simple screw terminals

The screw terminals for the wires allow the connection to be made without breaking the cable structure. The terminal reliably holds wires even from different alloys such as copper and aluminum.

The design of the device is a channel made of metal (bronze, brass) of small length with a small diameter. The channel has two threaded holes for fixing screws. Usually in everyday life, one-way screws are used on a polyethylene base or made of plastic. The connection of the two segments is made by installing the end parts into the channel from both sides, after which they are fixed with screws.

Various clamp configurations can be found depending on the installation parameters. These include:

- wire diameter;

- insulation class;

- number of contact points;

- current characteristics.

Screw terminals are suitable for all technical conditions common in the domestic sector.

Self-tightening and lever-operated clamping structures

Such mechanisms are characterized by increased ease of use. To work with self-tightening disposable clamps, it is enough to insert the stripped end of the wire into the hole until it stops.

Lamellar clamps for connecting a conductor have a spring inside that prevents the conductor from escaping. When laying inside the cable, the plate is pressed by the core and blocks the wire. To pull out the wire, if necessary, you will need to squeeze the plate through the hole in the second row using a screwdriver. This type of clamping device is capable of withstanding 3-4 re-connections.

A more convenient configuration is considered to be where levers are used instead of screws. The wire is lifted with a plate that is secured by a lever. To operate such a device, it is enough to raise the lever, insert the cable into the channel and lower the mechanism until it clicks. To pull out the wire, follow the reverse procedure.

Connecting insulating clamps

Spiral wire clamps are used to connect small-diameter conductors. Several wires are stripped, formed into a group and covered with an insulating mechanism until they stop. To securely fix the cap, turn it several times. Several strands are pulled together by a conical spiral. When the cap is screwed on, the group of cables is tightened into a single knot.

Plastic cap connectors for low power wiring are used. Also, such clamps are used when installing electrical networks inside the house.

Types of caps:

- without thrust protrusions;

- with persistent protrusions.

The second type is used for wires with a large diameter.

Piercing clamping mechanism

Power lines up to 1 kW use piercing clamps. They allow you to connect sections with a cross section of 1.5-10 sq. Mm on branch lines and with an area of 16-95 sq. Mm. on trunk lines.

Structurally, they represent a metal girth, which is covered with insulation. It is compressed with a stop bolt. Metal teeth are applied on the wrap-around plate, which pierce the insulation and dig into the conductor itself, fixing it securely.

The advantages of electric cable puncture include the possibility of refusing to remove the insulating layer. Also, when working with a clamp, a power outage on the line is not required. A high level of sealing is created in relation to atmospheric influences, such as ultraviolet radiation, moisture.

Piercing mechanisms for self-supporting insulated wire

With the help of such mechanisms, it is possible to connect the self-supporting insulated wire to a bare wire without wasting time stripping the insulation. Made of fiberglass and polymer reinforced.

There are two types of clamps for self-supporting insulated wire:

- with one bolt;

- with two bolts.

The first method is also called bare SIP. Suitable for connecting bare wires to self-supporting insulated wires.

The second two-bolt method is used in connection on main lines. The body is made of glass-reinforced polymer.

Clamp between nut and bolt

A simple and reliable fixing method using bolt clamping devices is actively used in power networks.

The connection will require the following parts:

- bolt of the appropriate diameter;

- nut;

- washers;

- lock-nut.

This method can even connect conductors of different materials.

Clamps for other purposes

In addition to the mechanisms that are used to connect electrical conductors, there are models for other tasks. These include clamps for fastening suspensions, for test tasks, such as "crocodile" and others.

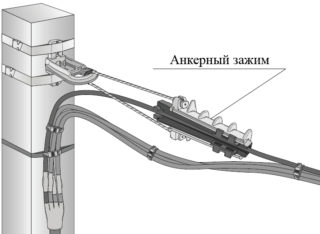

Anchor type clamps for fastening

This device is not used to connect wires. It is designed specifically for mounting - hanging fasteners. There are different configurations of anchoring clamps for vulture wires. These include:

- models for self-supporting systems;

- insulated neutral models.

The mechanisms themselves are easy to use. For fastening, there is an opening arc, on which brackets, hooks and other devices can be installed, which will then be attached to the body of the electric wire clamp.

Clips for test tasks

There are many applications in electronics and electrical engineering that require clamps for test use. This can be to test the functionality of the device with a tester, measure the current or voltage level, or temporarily connect to a power source.For such work, sliding or push structures with spikes, which are called "crocodiles", are suitable. They are made of metal and covered with PVC insulator. The toothed part must be open.

Test clamps can be divided into two large groups - for high voltage and low voltage electronics. Their difference lies in different boundary conditions for current and voltage. When working, it is important not to mix up the types of test clamping mechanisms, so as not to damage the device.

Correct cable connection

The correct procedure for connecting cables using clamping mechanisms guarantees high-quality, safe and stable contact. To correctly connect the two cores, you need to follow the given algorithm.

Step by step instructions for connecting cables:

- Removing working conductors to the point of contact.

- Disconnecting the network, pulling the device out of the socket, if a wire is being built up on household appliances.

- Stripping of insulation at the point of entry into the terminal. You can clean the ends with a knife or using a special tool. The latter option is preferable, as professional equipment will not damage thin conductors. Stripping is carried out until the characteristic shine of the wire appears.

- Installing bare cable parts inside the clamp sleeve.

- Fastening in an appropriate way. These can be electric punctures, contraction, squeezing and other types of fixation.

If necessary, you can additionally insulate the contact point.

Usually, the work of connecting wires using different devices is carried out in junction boxes, so safety precautions must be observed.