The method of connecting cables of electrical wiring depends on the requirements of the operation, ensuring the safety of communications. The main methods are welding, mechanical stranding, installation of terminal blocks. Using terminal blocks is a simple and reliable way to connect any type of wire. Wire clips speed up installation, allow connection renewal. Their use ensures the reliability of wiring performed independently, without the involvement of an electrician.

- Basic requirements for terminal blocks for connecting wires

- Advantages and disadvantages of terminal switching

- How to choose the right terminals for wires

- Types of electrical connector blocks

- Spring loaded

- Screw

- Knife type

- Terminals on plastic blocks

- Terminals for connecting wires

- Clamps for branch type "nut"

- For junction boxes

- With fuse

- What terminals for switching wires is better to use

- Overview of manufacturers of wiring devices

- ABB

- WAGO

- Legrand

- Wire connection technology with terminals

Basic requirements for terminal blocks for connecting wires

Wiring accessories are manufactured according to special standards and norms. There are several requirements for terminal connectors:

- Resistant to high temperature and combustion. Materials used for the body are self-extinguishing in case of fire. Polyamide is recommended, used by WAGO and Legrand.

- Reliable and fast contact fixation. It is recommended to leave a sufficient length of the communication cable so that there is no tension.

- The properties of the clamps should not change during the period of operation.

- The size of the contact plates must prevent the contact of strands of different materials. To ensure low resistance, copper and brass parts are coated with a special paste.

- Information about the main characteristics of the device is applied to the body of the product.

One of the essential requirements is protection against accidental access.

Advantages and disadvantages of terminal switching

To connect the power cable outdoors or indoors, the simplest option is to use connection terminals for the occasion. The main advantages of the method:

- constructive variety of connectors;

- the possibility of dismantling and repairing;

- simplicity, speed and availability of installation;

- electrical safety, dielectric housing protects against electric shock;

- resistance to mechanical stress and vibration;

- the possibility of switching metal conductors of different cross-sections and materials.

Disadvantages:

- allocation of additional space in panels and junction boxes;

- high cost for large-scale works.

The electric clamps are durable and reliable; it is enough to have a screwdriver to install them.

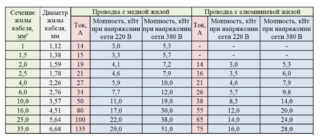

How to choose the right terminals for wires

Before purchasing connection terminals for wires, it is necessary to examine the power cable. You will need the following information:

- section;

- number of lived;

- conductor material.

An important criterion is the rated current. This characteristic is indicated by the manufacturer. If it is not enough, the connector will start to heat up and melt. The material of the case matters. For household appliances, sockets and switches, products made of polypropylene and polyamide are suitable. It is recommended to install ceramic devices in power busbars. The last criterion is the size of the terminal. It needs to be compact to fit in tight spaces.

Types of electrical connector blocks

Devices for wiring switching are selected depending on the purpose. The best option is selected among the many models. There are several ways to fix conductors in strips.

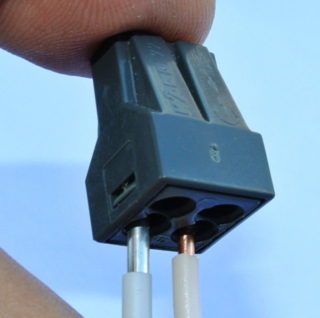

Spring loaded

A common version of spring-type products is self-clamping terminals. They are disposable and reusable. In the first case, after fastening, the wire cannot be pulled out without significant damage. On reusable models, it is released using a lever. Advantages of the method:

- no experience or tools are required for installation;

- the stripped end of the wire is fixed with a spring after insertion into the groove;

- the connection is reliable and durable.

Spring-loaded copper contact plates secure stranded wires without damage. The quality of the wiring connection does not depend on the professionalism of the master. Even a beginner can easily cope with the self-locking mechanism. The leader in the production of devices with automatic contact clamping is the German company WAGO. The downside is the high cost of products.

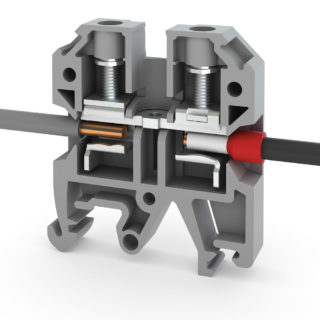

Screw

Screw-type connectors hold the wire to the bonding pad with the pressure of the screw. The metal clip is housed in a plastic case. Switch advantages:

- the ability to reuse;

- the block consists of many parts;

- installation is carried out with one screwdriver.

Disadvantages of screw shoes:

- vibration sensitivity;

- not recommended for aluminum cable;

- requires regular maintenance (tightening screws).

The screw type terminal blocks are not suitable for stranded wires. It is recommended for solid copper cable. When tightening the screws, a certain amount of effort is required, in order to make the connection correctly, experience is required. Well-known manufacturers of screw switches are Legrand and Wiedmuller.

Knife type

Knife switches are installed in the circuits of the neutralization system. They are recommended in areas where the wire is not cut for safety reasons. Their feature is that there is no need to remove the insulation from the contact. The wire is inserted into the terminal block, where a special knife cuts through the braid and securely fixes the core. This type of connector has its advantages:

- installation is accelerated;

- compact dimensions;

- no professional skills required for installation.

Blade terminal blocks are not used for power circuits; they are most often used to connect audio equipment.

Terminals on plastic blocks

Pads are used to connect two wires. They are available with different conductor hole diameters. The devices allow you to connect cables with one or more conductors, conductors of various cross-sections. The construction of the pads excludes oxidation processes when switching wires made of copper and aluminum. Some models are filled with an anti-corrosion paste. A special notch in the plastic prevents pressure on the core when tightening the screw. The transparent body of the products makes it possible to assess the condition of the contacts.

Terminals for connecting wires

Common designs for wiring crimp terminals include:

- Ring - round-shaped clamps are characterized by the most reliable contact due to the large contact area. They are recommended for low current and power networks. The products are in the form of a metal ring and a shank. Terminals are made of copper or aluminum. The sizes of products are presented in the range of 3-27 mm.

- Pin - detachable parts, consisting of two parts - plug and socket. These are insulated devices, the color of which indicates the power of the terminal block. The connection parts are marked with the symbols "A" and "B".

- Fork - Fork-type terminals are designed for screw mounting. They are used in secondary and power circuits. The materials for the products are aluminum, brass and various copper alloys.The clamps are designed as a fork with two prongs, with or without insulation. Suitable for wires not exceeding 6 mm in diameter.

- Knife-type - a common option for stranded wires of small cross-section. Terminals are used for household appliances - irons, refrigerators. The design of the products is "dad and mom". The color of the insulation depends on the power, the maximum parameter is 5 kW.

The use of terminals is the simplest and most economical option for switching electrical wires.

Clamps for branch type "nut"

The clamp for branching the main branch without separation consists of a plastic body and metal plates with bolts. The dies have grooves for contacts. When choosing a model, the cross-section of the main wire and the branch is taken into account. This connector can be used to connect aluminum and copper wires. There is a brass dividing plate between the two dies.

For junction boxes

The wires of all connected devices are brought into the junction box. Terminal blocks for junction boxes are designed for branching electrical wiring. Their body is made of polycarbonate, and the contact pad is made of copper. The fixation is carried out by a spring mechanism.

With fuse

The devices have an additional element in the design - a fuse. The terminals are oversized. They are installed in AC and DC networks. Scope of application - switching electrical appliances without built-in fuses and installation in a panel on a DIN rail.

What terminals for switching wires is better to use

Simple rules will help you choose the right terminals for connecting the wire:

- Focus on the technical parameters of the terminal blocks. The main characteristics are the nominal current and the diameter of the conductor. Marking is applied to the body of the product.

- If it is necessary to connect conductors from different metals, choose a block with a special filler. The paste prevents oxidation processes when switching aluminum and copper.

- Choose products from a material suitable for the operating conditions.

When choosing connectors, the quality of materials and workmanship plays a role; it is better to give preference to well-known manufacturers. Low-grade wire terminal block from China may cause short circuit or fire.

Overview of manufacturers of wiring devices

Fire safety depends on the quality of the products that you have to use when installing the wiring. Products of unknown companies can be made from cheap substitutes for brass and high-quality plastic. Renowned electrical manufacturers offer reliable terminal connections.

ABB

The ABB group of companies is a leader in the production of high-end electrical equipment. Its range allows you to choose products for any type of work. The brand offers terminal blocks for wires of the main types of connection: spring, screw, plug-in, insulation cut-out systems, etc. Product advantages:

- great quality;

- variety of models;

- innovative developments;

- reliability.

Essailec test blocks and ADO System terminal blocks are unique products of the manufacturer.

WAGO

The products of the German company WAGO have gained popularity due to their reliability and ease of use. The most popular are spring self-clamping terminal blocks. With their help, soft stranded and single-core cables of various diameters are fixed without damage. Product advantages:

- vibration resistance;

- contact connection speed;

- constant pressure eliminates deformation of the core;

- access of measuring instruments during repair is possible.

The reliability of the design is provided by a steel spring and a polyamide casing. The company offers clamps for detachable and non-detachable communication.They are suitable for wires up to 4 sq. mm.

Legrand

The Legrand brand has earned respect and recognition in the electrical infrastructure market. The company offers terminal blocks with screw and spring terminals. Product advantages:

- resistance to wire pulling;

- mechanical strength;

- easy installation;

- variety of sizes.

The contact pads of the devices are made of nickel-plated brass for improved current conductivity.

Wire connection technology with terminals

The functioning of the electrical network and devices depends on the correct switching of wires. The nuances of the connection depend on the type of terminal blocks. When working with self-clamping WAGO 2273 series blocks, it is enough to strip the wire from insulation in a section of 10 mm. Work is carried out carefully so as not to damage the conductive core. The end of the contact is forcefully inserted into the terminal hole.

The 222 and 221 series universal connectors have levers to secure the conductor. They are preliminarily raised up. After inserting the stripped core, the part is lowered. The devices are reusable and can be easily disconnected. Compact terminal blocks for wire are used in junction boxes. They are placed at a distance from each other to reduce the likelihood of heating and shorting.

Blocks of the 224 series are used for the installation of lighting devices. The terminal blocks for connecting wires have special holes for solid and multi-core contacts.

WAGO 773 connectors are disposable. The tip is inserted into the hole without insulation and is fixed with an internal clip. If necessary, take it out, making a scrolling motion. Checking the reliability of fixing the wire in the connecting device is performed by light twitching.