Installing socket outlets before placing outlet devices on them is a mandatory procedure, ignoring which is contrary to the norms of SNiP and can lead to electric shock to residents. If you intend to carry out this procedure in your house or apartment, you should study how to install a socket in the wall and how the course of work differs in buildings made of different materials - brick, wood and made of concrete blocks.

- Requirements for socket boxes

- Sizes of socket boxes

- Installation in concrete

- During drilling, the drill bit or bit hit the reinforcement

- Embedding a socket

- Installation in drywall

- Installation in tiles or false wall panels

- Tools and consumables

- Installation rules for the socket

- Markup

- Holes

- Installation of boxes

- Preparation of mortar and installation in a niche

- Before or after plastering

- Frequent mistakes

Requirements for socket boxes

A separate set of regulations for the installation of a socket box has not yet been developed. PUE prescribe to observe the general rules of electrical safety. Before carrying out work, the products should be checked for compliance with the following criteria:

- The receptacle must be made of durable material that can withstand the force with which the plug is removed. However, it should not be pulled out at the same time as the outlet itself. Designed for use in plaster or alabaster walls, the products are equipped with numerous protuberances and hooks to ensure stability of the fastening. For this purpose, the holes where the wires are wound also work.

- On the inside, ribs must be well formed, where the sockets are attached.

- The plastic used must not be flammable. For walls (except wood), this requirement does not matter, but its observance is necessary to prevent the ignition of nearby wallpaper or furniture.

It will also not be superfluous that a group of outlets can be combined using clips.

Sizes of socket boxes

The overwhelming majority of products of this type have a diameter of 7 cm. The sockets themselves are usually designed for this indicator. Depth is a variable parameter, and you need to pay attention to it when choosing the option that best suits your goals. If you plan to switch several wires in the cup holder (for example, the use of this product to replace the junction box), you will need to install a version with a greater depth. In general, the installation of outlets in deep sockets is easier.

Installation in concrete

Before you fix the socket in the wall, you need to hollow out a hole under it. An electric drill with a diamond crown is best suited for this, but due to the high cost of such a tool, perforating machines with a nozzle adapted for slitting concrete are more often used.

When preparing the recesses for installing the socket outlets in a concrete wall, it must be remembered that when performing these works in the room, a large amount of small dust particles are formed. It is required to prepare in advance protective respirators, ear and eye protection devices, as well as a vacuum cleaner, which will be used for cleaning at the end of the work.

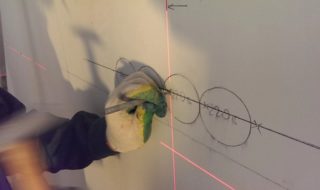

Before drilling, it is necessary to mark the grooves. The standard distance between the centers of the wells is 7.1 mm. Then you need to take a drill and make holes at the points indicating the centers. Then the maximum number of grooves must be drilled along the diameter of the circle. You can use a crown.

During drilling, the drill bit or bit hit the reinforcement

There are several methods to remove interfering reinforcement from reinforced concrete walls. The quickest way to do this is by drilling out the metal parts with a chisel for a hammer drill. It is allowed to use a spare crown. It can deteriorate in the process, so you should not use the same operation for this operation that is used for routine drilling.

Embedding a socket

The best way to install the socket outlets into the recesses is to smear the products with a mixture of rotband and alabaster. Before that, you need to clean the grooves with a vacuum cleaner and slightly moisten the walls with a damp cloth. The prepared solution is applied with a small spatula so as to provide the largest possible contact area with the product. The excess composition is then removed. The mixture is also applied to the socket itself and then inserted into place.

The installation of the cable can be carried out simultaneously with the installation, or first put in the socket and then lay the cable. Channels must be prepared in advance, where the wire is pulled between several devices. The wiring must not interfere with the socket enclosure, especially where the spacers are located.

Installation in drywall

In this case, the wire is laid in advance. Where the device to be mounted will be placed, a certain amount of wire is left. When buying the products themselves, you need to choose such that their ears, when opened, do not crawl out of the circle. The marking of holes, as in the case of a socket for wooden walls, is done in the same way as for concrete. The holes are drilled with a drill with a crown designed for working with wood. When installing plastic products in drywall, the wires are inserted into the socket before it is installed.

If the product is not well fixed, the easiest way to fix this is by installing a self-tapping nail into the base. Another option is to use a glue gun, having previously cleaned the recess from dust particles. If the gypsum base crumbles, it is primed and then the necessary places are covered with plaster mortar.

Installation in tiles or false wall panels

To insert the socket into an already lying tile, you need to use a special ceramic crown. In this case, it is better to gouge concrete with a diamond device to prevent damage to the tile. However, it is better to avoid such a situation and lay tiles only in a room where all the necessary sockets are already installed.

Tools and consumables

To carry out the work, you will need to purchase a building level for socket outlets, a mixture for nests, glue, a power cable, and protective equipment against construction dust worn on the face. You can mark the location of the nests with a simple pencil. You also need to stock up on all the required nozzles for the tool, which will be used to create holes. It will be useful to use a vacuum cleaner.

Installation rules for the socket

The product should be located flush with the finished surface, without protruding or sinking into the wall, hold well in the nesting recess. It must be installed strictly according to the level, even if it is only one.

The instructions for placing under-rosette products in the wall can be divided into three stages: marking the holes, shaping and mounting the parts themselves.

Markup

The installation holes for the sockets through which the operation of large household appliances (refrigerator, washing machine) will be carried out must be high enough - at the level of 1 m from the floor. For other nests, a height of 0.3 m is sufficient. At least 0.1 m must be retreated from the pedestals and countertops. You cannot put the outlet closer than half a meter from the elements of the heating system, as well as above the kitchen stove.

Holes

There are two options for arranging the holes. In the first case, the master works with a crown nozzle to a depth of 0.1 m more than that of the socket, and the core is removed with a chisel. In the second, the maximum number of holes is drilled along the contour of the hole using a conventional drill. For a brick wall, a tool with a drill from Pobedit is suitable.

Installation of boxes

The shrinkage is carried out in pre-coated niches, while the cables are left with a reserve of 0.1-0.15 m. The excess gaps are covered with a building compound.

Preparation of mortar and installation in a niche

From mixtures, you can use gypsum and alabaster. Gypsum hardens in 3-5 minutes, and if this is not a problem for the product to be installed, then the prepared solution will not work after this time. To increase the hardening time by 10-15 minutes, it is recommended to add plaster to the mixture in a ratio of 3: 2. It is permissible to use the putty as an independent base, but it does not hold the installed products as tightly as gypsum or mixtures with it. Before you smear the niche with the composition, it is sprayed with water from a spray bottle. At the socket, the plug for the cable is cut off, the box is inserted into the niche, the position is leveled and the excess solution is removed.

Before or after plastering

Technically, there are no big differences between these cases - the main thing is that the product does not stick out a millimeter from the wall. When plastering a wall with built-in protruding socket outlets, it will be difficult to apply an even layer along the entire length. You can first prepare the niches, then apply plaster (the holes will remain, their insides will need to be cleaned up) and then install the boxes.

Frequent mistakes

It often happens that during installation, the cable is interrupted with a spacer. This is very dangerous - there is a risk of a short circuit or an electrical potential on the socket housing. Other errors include:

- attempts to fasten products with polyurethane foam - it does not hold them well enough, besides, many samples do not meet fire safety standards;

- ignoring the use of the building level;

- work with a diamond core bit at the maximum possible depth with an inserted drill;

- installation of a single product in a place where there are many fittings.

Before mounting boxes for sockets, you need to correctly select their location and purchase the necessary tool. The installation procedure itself is quite simple and even an inexperienced master can do it.

It is NOT POSSIBLE to cut out the reinforcement !!!!! You can’t even bare !!! Especially in load-bearing walls and membranes.