The three-pole socket is used to expand the possibilities of connecting electrical appliances in residential premises. With the help of a branching device, it is possible to increase the number of simultaneously switched on loads up to 3. Self-installation is possible only after familiarization with the design and the existing classification of products of this class.

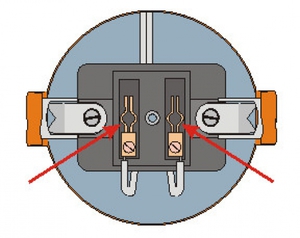

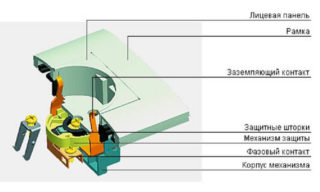

Three-pole plug device

Industrial products with three plugs are in demand and in great demand among the population. The main structural elements are:

- Traditionally made of durable and resistant plastic materials.

- The back cover is made of the same plastic, which provides reliable protection of internal spaces from accidental contacts, as well as from dust, dirt and moisture.

- Three sets of linear copper busbars used as connecting and distributing conductors (phase, zero and ground).

The socket cover is secured to the case with several pairs of reliable screw fasteners, suitable for a Phillips screwdriver. After removing it, access to all internal components of the product is opened, allowing it to be directly connected to the current power supply. The most important thing is to deal with the working buses to which the phase and neutral wires are connected, as well as the terminals for connecting the protective grounding conductor.

Features and classification of one- and two-pole products

Before understanding the features of installing a three-pole outlet, it is proposed to familiarize yourself with the classification of simpler analogs that have only one or two plug sockets.

Known samples of single and double-pole sockets differ in the following characteristic features:

- The electrical circuit used for bus wiring.

- Design features of execution.

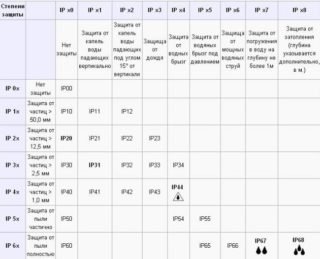

- Degree of protection against moisture and dust (IP).

In accordance with the first feature, they are divided into two-pole sockets with a grounding contact (having an additional bus in their composition) and 2-terminal samples. The former are installed in circuits with a 3-core wiring of the network cable, and the latter are installed only in two-wire lines, in which the presence of a third core is not provided for by the features of the cable entry. This type of wiring is most often found in apartment buildings of old buildings, where the lead-in cable has only two cores (phase and zero).

According to their design features, all products of this class are divided into sockets openly mounted on the walls of an apartment and into socket modules installed in special niches. They are suitable for the corresponding type of electrical cable routing (outdoor and concealed). According to the degree of protection, all these products are divided into several groups, each of which corresponds to a certain level of enclosure tightness.

When choosing this indicator, you should decide on where in the apartment or private house it is supposed to use the purchased model. If it is intended for installation in rooms with a high level of humidity (in bathrooms, showers or in the kitchen), it is necessary to select a socket with a high level of protection, at least IP55.A similar approach to choosing a product will be required when installing it in rooms with a high level of dustiness (in the attic or in the basement of a private house).

A modern two-pole socket in the external version can be equipped with a special protective cover and LED lighting. In the cases of more expensive and "advanced" models, a shutdown timer is sometimes built in. With hidden wiring, recessed type products are installed. They are housed in a plastic junction box, and the lead wires are tightly walled up in the walls.

Self-assembly

Before self-installing sockets of any type, you will need to familiarize yourself with the basic methods of their installation, corresponding to the two options for laying the lead wires.

Outdoor way

A three-pole plug socket, intended for outdoor installation, is mounted directly on the wall of the room or on a special socket, fixed to the wall surface. The connecting wires are led to it along the same plane and are placed in a plastic cable channel, from which the protective cover is previously removed. After laying a bundle of conductors into it, the latter are fed to the socket housing and connected to the corresponding contacts.

To connect the wires to the terminals (connectors), the socket cover must be removed from the housing. Upon completion of the installation operations, the product is completely assembled, the covers of the cable ducts are returned to their place.

Recessed option

When a recessed socket is installed, a niche in the wall is prepared for it, in shape corresponding to the contours of the installation box. To cut wall material, you will need a special tool called a wall chaser. If there is no such device in the household, it is allowed to use an ordinary grinder to cut grooves.

Several grooves are cut in the wall in the installation area along the longitudinal axis, which are aligned with a chisel in the form of a rectangle of the desired size. Subsequent operations:

- The installation box is walled up into the finished longitudinal niche.

- The lead wires laid in the grooves are connected to the outlet with the back cover removed.

- At the final stage of work, the cover is returned to its place, fixed in the installation box by means of spacer screws.

Next, it remains to brick up the sections of the walls with the supply wires and close the outlet from the outside with a decorative panel.

Choosing the right product

When choosing a suitable sample, you will need to carefully read the technical characteristics of the outlets offered in the store. In this case, it is necessary to proceed from the following indicators:

- main dimensions: length, width and depth;

- number of poles: one, two or three;

- mounting method: open or recessed options;

- the presence of a grounding contact and additional accessories: LED indicator of the mains power supply, for example;

- method of fixing the lead wires: by soldering or by a fastening screw.

The model is selected taking into account the technical parameters that fully meet the user's needs.