The stretch ceiling is aesthetically pleasing. In addition, it is quite functional in terms of lighting arrangement. Users should figure out how to install spotlights in a stretch ceiling so that the PVC film is not damaged by sharp objects and heating by light beams. In fact, there is nothing complicated in this process.

- How to choose lamps

- Popular installation schemes

- Ceiling markings

- Distance between spotlights

- Calculation of the number of light sources

- Materials and fixtures

- Manufacturing of a fixture for a luminaire

- Cable connection

- Terminal blocks and piercing clamps

- Thermal ring installation

- Installation of the luminaire in the ceiling

- Connecting luminaires with a driver

- How to add fixtures to an installed stretch ceiling

How to choose lamps

The canvas of the stretch ceiling can turn yellow under the influence of high temperatures (from +45 degrees) and lose its elasticity. To avoid such a result, it is necessary to correctly select and install the lamps.

For stretch ceilings, as a rule, they choose lamps with LED or halogen-type lighting sources, very rarely - with fluorescent-type sources.

A suspended ceiling limits the power performance of light sources by its properties. The power of halogen lamps should not exceed 40 W, and fluorescent lamps - 50 W. Also, when choosing lighting devices, you need to pay attention to their design features.

Spotlights are the best option for installation in stretch ceilings. They are small in size, designed for one low power lamp or for several integrated LEDs. The LED lighting fixture does not need lamp replacement.

Spot-type luminaire bodies can be completely built into the ceiling sheet or protrude slightly beyond its plane, which contributes to better heat dissipation. The latter are preferable for installation in rooms with low ceilings. They minimize the distance between the base and the ceiling fabric.

Popular installation schemes

The main advantage of using spot-type luminaires is their ability to make lighting even, very soft and diffused. They are also extremely economical to operate. Such lighting devices can be controlled by means of switches, which makes it possible to regulate the consumption of electrical energy. Combined with multi-level ceiling structures, spotlights give the interior a unique architectural design.

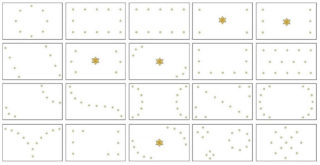

Installation of luminaires on a stretch ceiling is possible according to the following schemes:

- Parallel placement in 2 or more rows is ideal for long and narrow rooms.

- Rectangular placement - visually expands the room space, goes well with the central chandelier.

- Staggered arrangement - well suited for rooms with an "island" where it is necessary to illuminate the corners of the room and its center, for example, the kitchen.

- Arched placement - allows you to accentuate a specific part of the room, for example, a work area or a transition in multi-level ceilings.

- Chaotic arrangement of light sources in the style of "Starry Sky" - well suited for rooms without symmetry, where furniture is arranged in a non-geometric order, for example, a living room.

- The cruciform arrangement is an excellent variation for small interiors where it is impossible to install massive chandeliers and pendant lamps.

- Square schemes without central lighting are a practical and optimal option for hallways and bathrooms.

These are just the basic layouts of the light points. The options available are not limited by anything, except for the designer's imagination.

Ceiling markings

Before installing the luminaires in the ceiling, it is necessary to mark their mounting places even before stretching the ceiling sheet.

Two methods can be used:

- using a pencil and tape measure;

- by means of a laser level.

If a level is used, the initial markings can be created on the floor, and then transferred to the ceiling using a laser.

It is not very convenient to work with a tape measure on the floor, so you can make a template for placing lighting fixtures in advance. For example, use a piece of skirting board or cable of a specific length, which corresponds to the distance between the fixtures.

After the ceiling sheet is stretched, it will be easy to transfer the markings on the floor to the finished ceiling.

Distance between spotlights

You need to decide where the spotlights will be installed before fixing the canvas to the ceiling. This is especially important for multi-level ceilings, where each of the tiers is distinguished by a separate lighting contour.

Places of lighting fixtures are distributed in such a way that they do not fall on the baguettes. The minimum distance between the baguette and the luminaire hole is 25-30 mm.

The recommended distance between lighting fixtures is 30 cm.

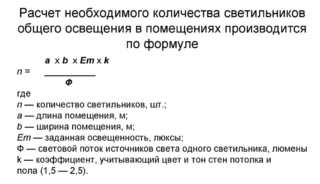

Calculation of the number of light sources

Materials and fixtures

To install and connect spotlights, you will need the following materials and tools:

- long nose pliers;

- construction tape;

- stationery knife;

- standard screwdriver with indicator;

- wire stripper;

- wire VVgng 3x1.5 mm2;

- perforated mounting tape;

- electrical clamps;

- puncher;

- thermal rings;

- dowels.

You need few tools, most of them are available for every owner of the house. Some materials have to be purchased, but these costs are low.

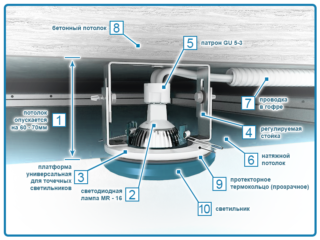

Manufacturing of a fixture for a luminaire

At the very beginning of the installation of the luminaires, a mortgage is made. For such purposes, there are already finished products:

- universal;

- for a specific diameter.

In universal products, a hole is cut out in accordance with the diameter of the lantern. After that, even at the bottom, the body is tried on to it in order to avoid sudden problems when stretching the ceiling sheet.

The largest distance between the bottom edge of the profile and the base ceiling is measured. This is necessary in order to cut the perforated tape to the required length.

Next, you need to bend the cut off punched tape, giving it a U-shape. The dimensions directly depend on the diameter of the lamps used. Then the tape is attached to the mortgage by means of small self-tapping screws ("bugs").

Instead of a mounting tape, special adjustable-type stands can be used. They are stiffer, but less versatile.

After assembly, the entire structure is attached to the main ceiling. Holes are drilled with a perforator, according to the previously made markings, and the mortgage platform is screwed in by means of dowels.

Cable connection

The supply cable for VVGng marking is laid before stretching the canvas in accordance with the route of the placement of the light points. The minimum cable cross-section is 1.5 mm2. Less can not be used even with light loads.

At the location of the lighting device, it is necessary to leave a supply of cable in the form of a small loop (it is further cut). This loop should drop to a level of at least 10 cm from the finished ceiling.

Terminal blocks and piercing clamps

The loop from the cable is cut in half, the protective insulation is removed from the wires by 10 mm and they are connected back through the terminal block. The free remaining terminal will serve to connect the power cable from the light point itself. This type of connection is called parallel.

If you use piercing clamps instead of terminal blocks, you do not need to cut the loop from the cable. When using them, only the upper protective sheath is removed from the cable, the inner cores remain intact. They must be inserted into the piercing clip, into its upper part, and the device must be snapped into place. The integrated blades automatically pierce the insulation layer to form a secure contact. The wires for the light point are connected to the bottom of the clamp in the same way.

After mounting the terminal blocks, the entire group of spotlights is connected to the power cable. After that, the presence of voltage at the end contacts is checked using a screwdriver with an indicator.

Thermal ring installation

After connecting the cables, it is necessary to put a thermal ring of the required diameter on the canvas, using special glue for this. These rings are made of heat-resistant plastic. It is able to withstand temperatures up to +90 degrees for a short time.

The thermal ring has two main functions:

- protection of the canvas from the temperature effects of lighting devices;

- mechanical protection - before making a hole in the stretch ceiling for a spotlight, it is imperative to glue the thermal ring, it will not allow the canvas to disperse at the cut points.

The glue is applied evenly around the entire perimeter of the ring. There should be no non-glued areas. You do not need to run your finger along the ring when it is pressed against the ceiling, because of the glue it can slide to the side. Enough simple pressing.

Then, carefully using a clerical knife, the canvas is pierced and a hole is cut inside the ring.

Installation of the luminaire in the ceiling

Before installing the light fixtures in a regular place, you need to trim the mortgages. They should come close to the canvas, without pressing on it.

It is necessary to lower the cable outside and, using the terminal blocks, connect the phase with zero to the wiring of the light point. If the supply cable is three-core, the third core is connected to the luminaire as a ground. If the body of the device is plastic, it is simply not used.

After connecting the wiring, the luminaires are inserted into their regular places and secured by means of spring "legs".

Connecting luminaires with a driver

Almost all modern spotlights are equipped with their own power sources - drivers. In this case, the voltage is supplied through them, and not directly to the LEDs. Drivers are built into the case and external, connected to it via a connector.

To connect the drivers, voltage must be applied to the supply wires marked "N" and "L" - zero and phase, respectively. The output voltage indicator from them is already reduced. Output wiring is identified by the “+” and “-“ symbols.

After completing the connection, the driver with the wires is hidden behind the thermal ring, after which the luminaire can be installed in its regular place.

How to add fixtures to an installed stretch ceiling

To add light points to an already installed ceiling, you will have to dismantle the canvas. It can be removed partially or entirely, depending on the location and the number of added fixtures.

Not every canvas involves re-assembly after removal. It all depends on the method of its initial attachment. The easiest way is to re-put the canvas, which is fixed by the harpoon method. It will be a little more difficult if the mount is of the clip type. It is literally impossible if the type of fastening is glazing.

If we consider the harpoon type of fastener, the algorithm for adding light points is as follows:

- The old canvas is dismantled.

- Additional markings are made on the main ceiling.

- Additional embedded platforms are installed on new tags.

- Additional cables are laid for new light points.

- The canvas is mounted in place.

- In the right places, new thermal rings are glued, in which holes are cut.

- Additional luminaires are installed in their regular places.

The process is very time consuming and entails considerable financial costs. It is better to entrust its implementation to specialists, and not do everything yourself. This can damage the canvas, after which you will have to order the installation of a new one.

With an even base, the stretch ceilings into which the lamps are being installed always give a sag of 3-3.5 cm.It turns out that if the embedded platforms are placed slightly above the ceiling profiles, the lighting device will be pressed into the canvas. Therefore, they need to be lowered close to the ceiling, but only after stretching it. Embeddments should not touch the canvas, you should step back from it by 1-2 mm.