LED strip is a fairly common decorative element. This is due to the ease of installation, reasonable cost and excellent decorative properties. It is a flexible canvas no more than 5 meters long. One side is equipped with LEDs and the other with adhesive. Another advantage of such a tape is that it can be attached to any surface, built up and cut. The installation process is simplified by special profiles that easily give the tape the desired shape, and also make it possible to implement even the most daring design decisions.

What is a profile for LED strip

A profile for an LED strip is a versatile item that serves not only as a protective case, but also as a heat sink to prevent overheating of the LED strip. Profiles are divided into two types - equipped with a transparent diffuser and matte. The device is used for any type of lighting fixtures: for chandeliers or decorative spotlights.

Profiles are most often used to illuminate architectural structures, shop windows, counters, billboards, or to correctly highlight accents at home.

The main types of profiles for lighting

According to the material of manufacture, the profiles are divided into aluminum and plastic. The plastic boxes include polycarbonate. The advantage of this material is its elasticity, which makes it possible to make rounded frames. Other advantages of plastic profiles:

- low cost;

- ease of installation;

- elasticity;

- the ability to choose a transparent or plastic case;

- different texture (surface, color).

Compared to aluminum, plastic has the worst thermal conductivity and tape cooling.

Metal profiles are made from aluminum only. They come in different lengths - 1150, 2000, 2500 mm. The advantage of the material is the removal of heat from the lighting source, in this case, diodes.

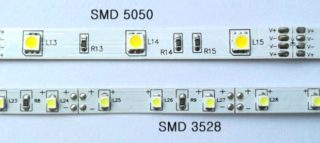

LEDs of the SMD 3528 type and their analogs do not need a heat sink. Samples SMD 5050 must be installed on surfaces with low thermal conductivity.

Aluminum boxes are most often used to decorate lighting in the kitchen, in public places and on steps. A special tape is used to seal the case if it is mounted outdoors or in rooms with high humidity levels.

Profiles are attached to surfaces using double-sided tape, self-tapping screws or glue. When using scotch tape, it is important to familiarize yourself with its operating temperature beforehand, as most products lose their adhesive power when heated.

Products are divided into several types and by the method of installation.

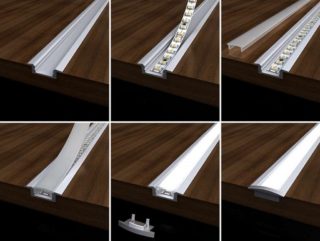

Corner

This type is used to install LED strips in the corners of building structures, cabinets or, for example, commercial equipment. With their help, it is possible to effectively hide all the unevenness of the joints.

This option is preferable if you want to provide lighting at an angle.By themselves, diode light sources emit light irritating to the eye, so it is imperative to additionally install a diffuser (almost always included in the kit).

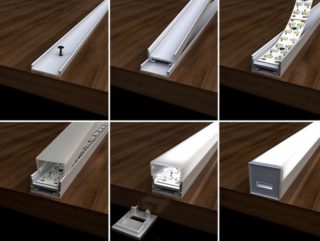

Built-in or mortise

The main difference between the built-in type is the presence of special protrusions that hide the uneven edges of the material at the installation site. There are two ways to install:

- A groove is made in the material, and the profile itself is inserted into its cavity.

- They are mounted in places where the material changes. Example: a line connecting a board and drywall, plastic panels of different colors. The hidden structure is beyond the reach of the human eye; it sees only a light strip.

The second method is more common, since the modern design of premises involves the use of different materials and textures, which can be combined thanks to LED strips.

Overhead

These models are considered one of the most demanded and popular products. You can install them on any flat surface. Attached to it with high-quality double-sided tape, self-tapping screws and glue.

As a rule, the kit includes not only a profile, but also a special cover made of plastic. Matt or transparent polycarbonate serves as a diffuser. The type of cover will depend on the purpose of the lighting. Matte profiles are used for decorative purposes, and transparent ones for lighting. The end side is closed with a plug.

The bodies have different geometric shapes - circle, cone, square, rectangle.

You can make LED luminaires from overhead profiles yourself.

To illuminate the glass ends

In hardware stores, a wide range of profiles for illuminating glasses of 8 and 10 mm is presented, which are used for mounting tape and fixing glass. Recently, acrylight technique has been used more and more often in the design of apartments, houses and other premises. The bottom line is to apply a pattern to plexiglass or any glass surface using laser engraving. The image becomes visible only at the moment when the front side of the profile is illuminated with LEDs.

Suspended

Suspended profiles are similar in appearance and technical characteristics to overhead structures. The difference is that the outer side of the product is smooth. The ease of installation, processing and, if necessary, cutting allows you to make a large number of lamps of different lengths with your own hands.

Installation of the channel for the LED strip

To securely fasten profiles of different shapes, lengths and types, you need to follow a few simple rules.

The main task of the design is to remove heat so that spontaneous combustion of an electrical device does not occur.

A cover channel that is attached directly to the surface loses more than 1/3 of its cooling capacity due to adherence to the base. For correct installation, you need to use special factory clips, thanks to which a gap of 3 mm is formed.

It is recommended to use a mounting base for surface mounting. A profile is mounted on it. Alternatively, shims are made from any available material first.

If installation with air access to the base is not possible, it is required to give preference to profiles with high sides, their height ranges from 15-20 mm. It is also not recommended to install the profiles with the sides close to the surfaces. This applies to mortise and corner models.

If we are talking about an internal profile, it is better to give preference to structures with external wide projections, thanks to them excellent heat dissipation will be provided.

LED strips with a power higher than 9.6 watts / meter must not be installed in corner and cut-in profiles.

When purchasing diffusers, it is important to consider the light transmittance:

- matte - 60%;

- semi-matte - 70-75%;

- transparent - 90-95%.

Both sides of the profile must be closed with end caps, otherwise moisture, dust and dirt penetrate inside. It is possible to mount built-in structures into the floor only in those places where the sections of the electric cable are not subjected to heavy loads.

Installation of LED strips in profiles with diffusers is very popular. Without much effort, with a minimum amount of knowledge, experience and tools, you can independently make and install a lighting fixture. There is a wide range of LED strips and profiles in hardware stores.