Property owners often struggle to decide which wiring is better - copper or aluminum. This question arises before private developers and owners of city apartments in which major repairs are planned. Not only the operational characteristics of the housing, but also the safety of the owners' residence depend on the correctness of the decision taken. In order not to be mistaken in the choice of wiring, it is necessary to understand the pros and cons of each material, to find out the general points and fundamental differences.

What to look for when choosing wires

When choosing between copper or aluminum for wiring, it is necessary to start from several criteria on which the efficiency of the electrical system depends.

You need to pay attention to the following nuances:

- Locations of sockets, lighting devices, packet and key switches. Based on the diagram, you can calculate the required length of the cable.

- The total power of devices that will be simultaneously included in the network. The result is an indicator of the maximum current load of the wires.

- Outlet standard. They are adapted for connection of conductors with a diameter not exceeding 2.5 mm. The current load and electrical conductivity of metals are related.

- Material cost. This parameter should be the last one to focus on, since safety comes first.

Do not forget about such a criterion as durability. Replacing communications is too expensive and time-consuming to carry out every few years.

Aluminum properties

Aluminum belongs to the category of light, chemically and biologically inert metals with a specific gravity of 2700 kg / m³. The material is safe for humans and the environment.

Advantages of aluminum:

- Affordable cost. The price is determined by the lower melting point and lower production costs than other metals.

- Plastic. The wire bends well, keeping its shape. The conductors are given any configuration required for operation.

- Formation of a protective layer. After cleaning, the surface of the metal is covered with a thin layer, which prevents its oxidation throughout the entire volume.

However, aluminum has the following disadvantages:

- High resistance to electron flow. This causes the lines to heat up, which can ignite the finishing materials.

- High level of thermal expansion. This leads to a weakening of the contact connections. With frequent switching on and off of lines with high load, the circuit is disconnected.

- Oxidation on contact with air. The resulting film has poor conductivity, due to which the contacts overheat and melt the insulation, and the "ground" line simply ceases to fulfill its function.

- Short service life. He does not exceed 30 years with an average load.

Today, in accordance with the requirements of GOST, the use of aluminum is prohibited in the construction of residential buildings and engineering structures.

Copper properties

Copper is a heavy metal with a specific gravity of 8700 kg / m³. This indicator should be taken into account only when laying power lines with a limited margin of safety for the supports. In everyday life, they can be neglected. The material actively interacts with oxygen, forming an oxide - a patina that can be seen on statues, fences and souvenirs.

The advantages of copper are as follows:

- Durability. If the line does not run outdoors, it can last 30-50 years, depending on the humidity in the room.

- Strength. Copper is resistant to twisting and bending. A quality cable can be deformed up to 100 times without losing its performance.

- High conductivity. The metal allows electrons to pass well, without undergoing heating and thermal expansion.

- Flexibility. The harness easily takes the desired position, straightening after the termination of the load. It is convenient to work with cables during installation.

The material also has disadvantages:

- High price. This is explained by the difficulties of ore mining and the costs of its processing. It takes a lot of energy to melt the concentrate, plus transportation costs.

- Oxidation when interacting with water and air. The resulting film degrades the conductivity of the contacts and contributes to their heating.

Choosing between aluminum or copper wiring, it is advisable to dwell on the second option, since it has more advantages than disadvantages.

Which conducts the current better

The following operational characteristics of the laid line depend on the conductivity:

- losses due to heating from the flow of electrons;

- preservation of current parameters, which is important for sensitive devices;

- the degree of temperature rise of the cable during the operation of powerful consumers;

- presence or absence in the room of the smell from melting and burning wiring.

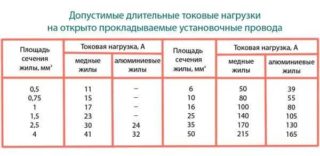

To understand which conducts current better - copper or aluminum, you can compare the degree of their resistance. The lower this indicator, the lower the likelihood of undesirable phenomena.

This indicator is:

- copper - 0.018 Ohm × mm² / m;

- aluminum - 0.028 Ohm × mm² / m.

Copper conducts current more than 1.5 times better. Resistance compensation is achieved by increasing the cross-section of the conductors in the cable.

Which wiring material is better

For all the advantages of aluminum, one should not forget about its disadvantages. The main one, apart from mechanical characteristics, is low conductivity. It is impossible to endlessly increase the diameter of the cable, since household appliances and channels laid in the walls are not designed for this. Do not forget about such a factor as the fragility of the metal. After several years of operation, it may burst when the socket or meter is replaced. It is undesirable to twist in a box, as it will not last long. Choosing aluminum will provide good savings in material procurement, but subsequent repair costs may negate these.

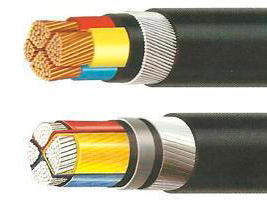

Copper also has its drawbacks, but they are offset by a large number of advantages. Even the process of pulling the cable through the channel is easier, since it bends well without any tendency to break or break. It is worth remembering about the low resistance. By installing a line with 2.5 mm² cores, you can use as powerful consumers in everyday life as the common house line allows.

Summing up, we can recommend the craftsmen to make their choice in favor of copper products. If the budget is limited, you can combine materials using modern switching facilities.

Helpful hints

The wiring diagram for the apartment consists of an upper and a lower level. To the bottom, there are sockets designed to power consumers, the power of which can reach 2 kW: washing machines, boilers, microwave ovens. In order not to expose the lines to the risk of overheating and burning, it is advisable here to run a copper cable with the maximum cross-section of conductors allowed for household outlets.

The upper level is used to power doorbells, ceiling and wall lamps. These products consume a minimum amount of electricity, especially if they are equipped with modern LED lamps.On top, you can run a thin and inexpensive aluminum cable, the power reserve of which will be enough with a large reserve. With such a solution, a separate question is a safe method of joining two incompatible metals with each other.

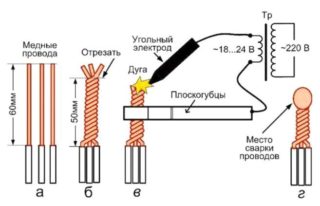

To avoid problems with contacts after installation, you can use one of the following devices:

- Clamp. The product consists of 3 steel plates. The cores are inserted between them, after which the plates are tightened with bolts.

- Bolt with 2 iron washers. The ends of the veins are twisted into rings and put on the axle, washers are installed between different materials. Tightening the nut ensures secure contact.

- Spring-loaded switch. Its terminals are treated with a special anti-corrosion grease. The cores are inserted into the grooves and secured with spring-loaded levers.

- Pads. They represent a steel bar with contacts, pressed into a plastic case. They are inserted into the ends of the cable into the holes where they are tightened with bolts. The products can be used to connect 2-10 wire pairs.

To avoid oxidation of wires, copper should be soldered, and aluminum should be covered with a special conductive paste.