Energy carriers help ensure the functions of all communication lines. In the temporary absence of the main highways, alternative sources of electricity can be used. They are not as popular as traditional ones, but they are more profitable in terms of operation and practically do not harm the environment.

- Where and in what form to get energy resources

- Renewable energy sources

- Using the energy of the sun

- Solar panels

- Solar collectors

- Self-made solar panels

- How a solar power system works

- Making a solar battery

- Solar panel installation rules

- Features of wind turbines

- Types of wind generators

- Wind turbine design

- Making a low-speed wind generator from a machine generator

- Heating a house with heat pumps

- Varieties of heat pumps

- How a heat pump works

- Heat pump from scrap materials

- Getting heat from other alternative sources

- Biogas plants

- Technology principle

- Biogas system for a private house

Where and in what form to get energy resources

Traditional energy sources are thermal, nuclear and hydroelectric power plants. The alternative energy supply is self-healing, efficient, cheap and environmentally friendly. In fact, energy is in natural resources, you just need to try to extract it. Without special skills, you can perform the following work:

- install solar collectors and batteries to power lighting or heat water;

- to mount wind turbines;

- use heat pumps to heat the house using the heat of water, earth or air;

- to use biogas plants for processing animal, bird and human waste.

The disadvantage of non-traditional energy sources is large financial investments for their organization.

Renewable energy sources

Due to the limited availability of fossil fuels, scientists around the world are developing and deploying the energy sources of the future. Renewable includes:

- Electricity generators - on the territory of Russia, electric, gasoline and gas generators are most often used. The latter runs on liquefied and natural fuel, due to its low noise, it is used in everyday life and is durable.

- Energy of the sun - a person uses electromagnetic radiation. The source of electricity and autonomous heating is noiseless and environmentally friendly.

- Wind turbines - operate on the basis of the transformation of the kinetic energy of the wind into the mechanical rotation of a turbine that generates alternating current. Horizontal and vertical wind turbines are characterized by high efficiency.

- Biofuels - the best options would be oilseed fats, algae, gas from the fermentation of organic waste.

- Waterwheel stations are a convenient source of energy if there is a river near the house. The turbine wheel is driven by water currents.

- Geothermal solutions - in seismically active areas transform the heat generated at the time of the release of geothermal water.

Russia has several solar stations - in the Orenburg region (power 40 MW), in the Republic of Bashkortostan (power 15 MW), in the Crimea (10 pieces of 20 MW each).

Using the energy of the sun

Alternative electricity based on electromagnetic solar radiation is justified for people who have a summer cottage outside the city.The reason is the indicator of total power in good weather no more than 5-7 kW per hour. Several solar installations are popular today.

Solar panels

The assembly of devices is made from photovoltaic converters. Industrial elements are constructed from miners that generate current when exposed to direct light. In the private sector, silicon converters of the poly- and monocrystalline type are popular. The latter differ in efficiency of 13-25%, but polycrystalline is cheaper. The temperature range of the plates is from -40 to +50 degrees.

Solar collectors

Used to heat air or water. The user can set the direction of heated flows, organize a reserve in case of bad weather. Manufacturers produce three modifications of collectors - air, flat and tubular.

- Flat plastic. They are a black and transparent panel in one casing with a central copper coil. The lower dark element heats up when exposed to sunlight. It transfers heat to the copper coil, which heats the water. The flat collector is suitable for heating the water in the pool or summer shower. The disadvantage of technology is that many elements are required to heat large volumes.

- Tubular. They are in the form of vacuum or coaxial glass tubes. Water, heated by the sun, flows down them. The heat concentrated inside a special system heats the water in the storage tank. For the circulation of water flows, sediment is used. A tubular collector is a good solution for heating hot water and heating.

- Air solar collectors. The devices resemble flat plastic models due to the black bottom and transparent top panels. Dimensional installations are located on the east or south-east wall. In them, due to solar heat, it heats the air supplied to the house and utility rooms with special fans.

Solar energy is best suited for underfloor heating.

Self-made solar panels

Solar installations are an expensive alternative to traditional electricity. With your own hand assembly, you can reduce the cost of the structure by 3-4 times. Before you start creating a solar panel, you need to understand the principle of its functionality.

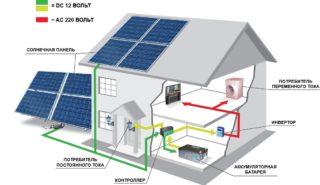

How a solar power system works

To represent the principle of operation, it is worth starting with the construction. The solar energy source device includes:

- solar panel - a complex of nodes for converting sunlight into an electron stream;

- Battery - there are several of them in the system, the number depends on the power of the consumers;

- charge controller - provides normal battery charging without recharging;

- inverter - converts low voltage current from batteries into high voltage current (3-5 kW is enough for a house).

Solar cells individually produce low voltage currents (about 18-21 V), which is enough to charge a 12-volt battery.

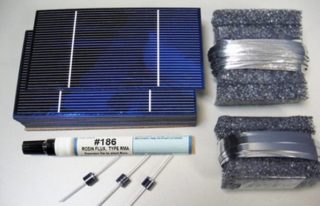

Making a solar battery

The battery is assembled from modular photocells. One household module contains 30, 36 and 72 elements. They are connected in series with a power supply with a maximum voltage of 50 V.

For the body part, you will need wooden beams, fiberboard, plexiglass and plywood. The bottom of the box is cut out of plywood and inserted into a frame made of 25 mm thick bars. Holes are made around the perimeter of the frame. To prevent overheating of the elements, the drilling step should be 15-20 cm.

For the bottom size, count the number of photocells and measure each one.

From the fiberboard with a clerical knife, a fiberboard substrate with ventilation holes is cut out. They are made according to a square-nesting scheme with an indent of 5 cm.Then:

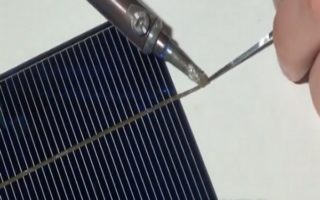

- The elements are placed on top of the substrate and unsoldered.

- Connections are made sequentially, orderly.

- The finished rows are connected to the busbars that conduct the current.

- The elements are turned over and fixed in the seat with silicone.

- Check the output voltage parameters. Its range is 18 to 20 V.

- The battery is run-in for 2-3 days to test the charging capacity.

- At the end of the check, the joints are sealed.

Paint and dry the backing 2 times.

After checking the functionality, the solar panel is assembled:

- Bring the input and output contacts to the outside.

- Cut out the cover from plexiglass and fix it with self-tapping screws on the holes made in advance.

- When using a diode circuit of 36 diodes with a voltage of 12 V, the paint is removed from the part with acetone.

- Holes are made in the plastic panel, diodes are inserted and soldered.

The last step is the installation and orientation of the solar panel to facilitate service access and energy efficiency.

Solar panel installation rules

Industrial modifications can rotate independently. Household devices must be set according to several parameters:

- Moving away from shaded areas - a tree or a tall house nearby will make the device ineffective.

- Landmark on the sunny side. Residents of the northern hemisphere orient the structure to the south, the southern one to the north.

- Tilt angle - tied to the geographical latitude of the site. In summer, it is better to tilt the solar panel 30 degrees to the horizon, in winter - 70 degrees.

- Availability of access for maintenance - cleaning of dust, dirt, adhered snow.

The device will be effective if the sun's rays are directed directly onto the cover.

Features of wind turbines

Wind power sources work on the principle of converting kinetic energy into mechanical energy, and then into alternating current. Electricity can be obtained at a minimum wind speed of 2 m / s. The optimal wind speed is from 5 to 8 m / s.

Types of wind generators

There are modifications according to the type of rotor mounting:

- Horizontal - differ in the minimum amount of materials for manufacturing and high efficiency. The disadvantages of the device are the high mounting mast and the complexity of the mechanical part.

- Vertical - operate in a wide range of wind speeds. The specificity of the generator is the need for additional fixation of the motor.

According to the number of blades, there are single or multi-blade models. By material, the blades are classified as sailing and rigid. The screw pitch of the installation is variable (you can set the working speed) and fixed.

During the construction of a wind turbine, a foundation is necessarily created and strengthened.

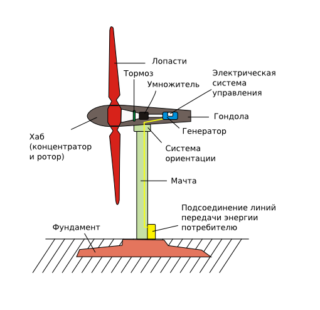

Wind turbine design

The finished wind generator consists of the following parts:

- tower - placed in a windy area;

- blade generator;

- blade controller - converts alternating current to direct current;

- inverter - converts direct current into alternating current;

- storage battery;

- water tank.

Accumulative battery smoothes out the difference in the wind season and calm period.

Making a slow-speed wind generator from a machine generator

Since the kit for assembling a wind generator costs from 250 to 300 thousand rubles, it is advisable to make the structure with your own hands. You will need a car generator and a battery.

The blades provide the operation of other wind turbine devices. You can make them yourself from fabric, metal or plastic pipe as follows:

- Choose a material with good wind resistance - from 4 cm thick.

- Calculate the length of the blade so that the pipe diameter is 1/5.

- Cut the pipe and use it as templates.

- Sandpaper the edges of all elements to remove irregularities.

- Fix the plastic blades to the aluminum disc.

- Balance the wheel by locking it in a horizontal position.

- Grind the edges of the wind wheel while rotating.

The optimal blade layout is a large number, but a smaller size.

A mast manufacturing project should start with material selection. You will need a steel pipe 7 m long and 150-200 m in diameter.If there are obstacles, the wheel rises 1 m higher than them.

For additional stability of the structure, pegs for stretching are made of steel or galvanized cable 6-8 mm in thickness. The mast and pegs must be concreted.

The process of alteration of the autogenerator consists in rewinding the starter unit and creating a rotor based on neodymium magnets. Holes are drilled in the device for them. The magnets should be placed alternating the poles and the voids should be filled with epoxy.

The rotor is wrapped in paper to rewind the coil in one direction in a three-phase scheme. At the last stage, the generator is tested - at 300 rpm it should show 30 V.

The more turns on the coil, the more efficiently the generator works.

Alternative wind sources of heat and electricity are collected after the pivot shaft is manufactured. You will need a pipe with two bearings and a tail section made of galvanized sheet 1.2 mm thick.

The generator is attached to the mast by means of the frame of their professional pipe. The distance from the beam to the blades should be more than 25 cm. After assembling the basic structure, the charge controller, inverter and battery are mounted.

Heating a house with heat pumps

Europe has been using heat pumps for several years now, interacting with all alternative forms of electricity. In summer and winter, the units take heat from the soil, air, water and send it to heat the room.

Varieties of heat pumps

Depending on the needs for heating, you can choose models with 1, 2, 3 circuits, 1-2 condensers. They will work for heating and cooling, or exclusively for heating.

By the type of energy source and the method of generating electricity, devices are:

- Air to water. Heat flows are taken from the air and heat the water. The systems are suitable for climatic zones with a winter temperature of -15 degrees.

- Earth-water. Relevant for the temperate climatic zone. They are installed in the ground by means of a collector or a probe without drilling permits.

- Water-water. Installed next to water bodies. In winter, the pump, by heating the source, provides heat to a large house.

- Water-air. The source of energy is a reservoir. Heat flows are supplied to the air by means of a compressor. It becomes a coolant.

- Earth-air. The soil is a source of heat, which is transferred to the air by the compressor. The carrier of energy is antifreeze liquids.

- Air to air. The devices work on the principle of an air conditioner - for cooling and heating.

The choice of a heat source depends on the geology of the area and the presence of obstacles to earthworks.

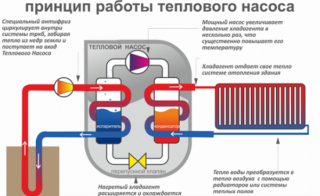

How a heat pump works

The heat pump operates on the basis of the Carnot cycle - an increase in temperature with a sharp compression of the coolant. Since the devices have 3 working circuits (2 - external, 1 - internal), a condenser, an evaporator and a compressor, the scheme of their operation can be represented as follows:

- The primary coolant (located in water, in air, in the ground) takes heat from sources with low potentials. The maximum node temperature is about + 6 degrees.

- The low temperature, low temperature carrier is in the inner loop. The refrigerant evaporates when heated, its vapor is compressed in the compressor. At this moment, heat is generated. Vapor temperature - from +35 to +65 degrees.

- The heat in the condenser enters the heating medium from the heating circuit. The vapors become condensate and are sent to the evaporator.

The cycle of the heat pump is constantly repeated.

Heat pump from scrap materials

Homemade is quite real if you have working parts from household appliances.

To prepare the condenser and compressor you will need:

- Make a pump compressor from a refrigerator or air conditioner compressor. The detail is fixed with a soft suspension on the boiler room wall.

- Make a capacitor. The best option is a 100 liter stainless steel tank.

- Cut the container in half with a grinder, and then insert the coil (copper tube of the refrigerator or air conditioner).

- After installing the coil, weld the tank halves.

Use argon welding for a quality weld.

The evaporator is built around a 75-80 liter plastic tank with a ”diameter copper tube coil. It is wrapped around a steel pipe 300-400 mm in diameter. The turns are fixed with a perforated angle.

A thread is cut on the coil for coupling with the pipeline. Refrigerant is pumped into the unit, after which the evaporator is mounted on the wall.

The optimal source for these alternative methods of generating heat and electricity will be water from a well or well. The liquid does not freeze even in winter.

You will need 2 wells:

- for water intake and its supply to the evaporator;

- to discharge waste water and enter it into the evaporator.

The autonomy of the heat pump will be ensured by automatic mechanisms for controlling the movement of the coolant along the heating circuits and freon pressure.

Getting heat from other alternative sources

When organizing the first external circuit of the pump, an effective heat source will be needed:

- Ring-shaped pipes in water. A reservoir without a large freezing depth or a river ensures the effectiveness of the technology. The pipes are laid under the water using a load.

- Thermal fields. The pipes are buried below the freezing of the soil - a large layer of soil is removed.

- Geothermal springs. Wells are drilled to great depths. Circuits with coolants are started in them.

- Outboard air. Heat is extracted from ventilation shafts or branch ducts.

The disadvantage of a heat pump is the high cost and cost of installing heat sources.

Biogas plants

Organic alternative electricity is produced using biogas systems. The devices allow you to recycle poultry and animal waste. The resulting gas is purified and dried, and then used as a heat carrier. Residual masses will be an effective and safe fertilizer for the soil.

Technology principle

Gases are formed during the fermentation of biological waste from animals and birds. An anaerobic environment without oxygen will be optimal. It increases the activity of mesophilic and thermophilic bacteria. For the process to be effective, the mass will need to be mixed by hand, using a stick or mechanical stirrers. Under ideal conditions, in 1 liter of a closed container heated to a temperature of +50 degrees, from 4 to 4.5 liters of gas is obtained.

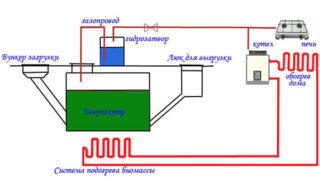

Biogas system for a private house

The simplest bioreactor is a container with a lid and a stirring mechanism. A hole is made in the cover for the gas outlet hose. Its quantity will be sufficient for 1-2 burners.

An underground or above-ground bunker increases the usable volume. The underground structure is made of reinforced concrete with a top layer of thermal insulation. The capacity is divided into compartments. The manure is loaded into the conveyor, filling the hopper to 80-85%. The rest of the area is used for gas accumulation. It is discharged through a special tube, the other end of which is in the water seal. After dehumidification, the purified gas enters the house.

Alternative types of extraction of heat resources and electricity are currently unavailable to residents of apartments. They can be used by residents of private houses and farms. The only drawback of renewable sources is the cost of arranging the system, but the financial investment pays off after 1-2 years of operation.