For continuous and uninterrupted operation of electrical networks, it is required to correctly install, maintain, and repair them. All of the above complex of measures forces specialists to use clips for wires of different configurations, sizes and materials of manufacture.

What are wire clips and how they work

A plastic clip or strain relief is the second most popular simple attachment piece. The wire is securely fixed and held thanks to the compressive action of the springy jaws. The wire clip is not intended for use as a hanger.

All configurations have identical design features, the main segment of the fastening is a screw that provides a reliable fixation. The assortment in hardware stores is very extensive, you can also purchase clips for adhesive mounting.

Clips for electrical wiring have one main feature of use - compliance with the strict correspondence of the bore hole to the wire diameter.

Each clip is designed exclusively for a single wire. If it is necessary to lay several cables, the fixing structures are installed with each other, and the contacting surfaces are equipped with a special system of protrusions.

Large size fastening structure is used to fix thin-walled metal pipes as well as flexible cable ducts. The diameter of wires, pipes, corrugations can reach 50 mm.

Popular types of clips for wires and cables

The use of a particular clamp is determined by a large number of criteria, for example, the purpose of the network, voltage and current, technical and operational parameters of the connections.

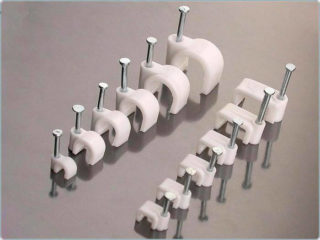

Clips with a carnation

The main task of the part is to fix a cable or wire, the diameter of which ranges from 6 to 14 mm. Operated, as a rule, for the installation of lighting and power circuits, computer, network, and telephone lines.

They are made of wear-resistant and heat-resistant polypropylene, the operating temperature of which is -5 - +140 degrees. The structure is attached to a wall or any other surface using a nail that is included in the kit. The component is made of hardened steel, length 4 - 12 mm.

Manufacturers declare that the part can be mounted to any surface with the exception of metal.

Clamps for installing PVC pipes or corrugations

If the wiring is laid in a corrugation or a pipe made of polypropylene, it is recommended to use elastic plastic clips, they are also called latches.

They are made by molding plastic under high pressure. Equipped with stiffening ribs, due to which a high grip strength of the corrugation or pipe is ensured. The working temperature fluctuates over a wide range thanks to the use of high quality plastic. The part is fastened to the surface with a screw. The size range of clamps allows you to reliably fix cables or wires with a diameter of 12 to 50 mm.

Decorative clips

In terms of design characteristics, decorative clips are identical to those with nails. However, the difference lies in the additional equipment with an attractive detail that securely fixes the wire and masks the wires passing along the wall.

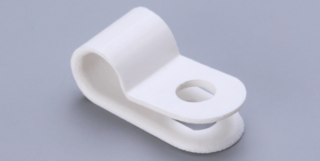

Cable clip KL

The simplest mounting method. The design has received the form of a clamp, it is made of metal or plastic. Thanks to a wide variety of sizes, it is possible to reliably fix wires and cables of different cross-sections. The diameter of the clip ranges from 5 to 20 mm. On the packaging and the product itself there is a type marking: KL-12, etc.

Dowel clamps

This type is intended for fastening round or flat conductors. With an open method of installation, it is considered the least noticeable among analogues. They can also be used when installing hidden wiring, in a strobe. They are extremely easy to use. The disadvantages include the low strength of fixation.

Fasteners for other purposes

Some types of clips are not designed to hold electrical conductors.

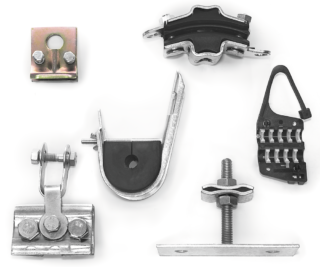

Anchoring clamps for fastening

These designs are designed to fix wires, the cross-section of which ranges from 2 to 25 mm2, the number of cores is from 2 to 4 pieces.

The design is simple, it consists of a polymer housing equipped with a self-adjusting clamping wedge.

Anchor clips are divided into two types:

- for insulated neutral carrier;

- for self-supporting systems.

The anchoring structure is easy to use thanks to the easy-to-operate bow. Most often, this part is mounted on hooks, hooks and brackets for subsequent fixation on a solid surface of electrical wiring.

Wire clips for test needs

Test clamps are often used in electronics and electrics. Such accessories are traditionally considered to be gear sliding structures made of metal. The toothed part remains open and the clamping part is carefully insulated.

A simple part is used for temporary engagement with wires, for example, for measuring mains voltage or current.

Test clamps are divided into two large types - for high-voltage electrical networks and low-voltage. The design parameters are identical, the only difference is the technical parameters for the current.

Fastening the wires

The technology for connecting wires with clips is extremely simple and straightforward. The implementation does not require special skills and a large list of required tools. You can do the work yourself without outside help.

- Mark the wall along which the wire will pass.

- Mark the locations for fasteners at equal distances.

- Fix the wire against the wall using the clips of your choice, usually with nails or screws.

When using dowel-clamps, you need to tuck the cable into the clamp, insert the clip into the previously prepared hole in the wall and push it all the way. This method is only suitable for lightweight wires.