In old houses built in the days of the USSR, in apartments directly under the electric meter there was a packet switch or, simply, a packet switch. For some owners, this device is still working properly, it is used for its intended purpose. With the help of power packers, the phase voltage and zero are connected to the electric meter and then through the linear machines they are wired throughout the apartment. This device duplicates the functions of the input circuit breaker, which makes it possible to refuse to install it in the switchboard, connecting the phase and zero directly to the terminals of the meter.

What is a packet switch

Despite the seeming archaism, the batch switch is still used in electrical circuits. By its structure, it is a purely mechanical device, manually operated with some effort. The complexity of its commutation is explained by powerful springs that fix the movable part in each of the working positions.

When it is turned in any direction, two groups of mechanical contacts are closed, and with a further half-turn, they also open. When connecting an apartment, for example, one pair of connectors breaks (closes) the phase supply circuit to the electric meter. At the same time, the second pair does the same with the zero core. Therefore, according to its scheme and functional purpose, the bag installed in front of the electric meter is, in fact, an input device.

Classification and labeling

Known samples of pouches differ in the following characteristic features:

- by the method of connecting the supply conductors;

- by the level of climatic protection;

- by the features of the switching mechanism.

In accordance with the place where the wires are connected, such a switch has two versions: with front or rear connection. According to the degree of protection of internal spaces, open models are distinguished, as well as partially or completely sealed products. By design features, switching mechanisms are divided into packet devices (cam) and drum type.

Regardless of the version, such switches have practically the same technical parameters and have the same disadvantages. For example, the resource of the spring mechanism of most models is no more than 103 commutations.

There are wear-resistant samples designed for a wider switching range (200-1000). The main condition for extending the working life of contact springs is that the frequency of their use should not exceed 50 times per hour.

When marking products of this class, the following alphabetic and numeric designations are used:

- the presence of the "B" icon means a switch;

- if there is a "P" sign on the case, it means a switch (or packet);

- the letter "G" means sealed;

- numbers 1-4 correspond to the number of poles;

- "H" is the direction with positions 2, 3, 4, and "P" is the reverse.

The designation of the device must indicate the degree of protection, as well as the type, installation features and rated current. On some models, badges are applied, indicating the material of the product case: heat-resistant plastic or silumin.

Design features

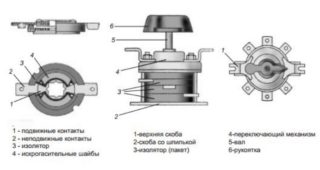

Electric bags are arranged very simply. They include the following units:

- product body;

- contact mechanical group;

- switching mechanism;

- rotary handle.

When considering the details of the switch, one should take into account its design, according to which it can be cam or disk. The working units of the first of these modifications have fixed contacts fixed on a square substrate isolated from the body. The movable unit of the contact group is made in the form of knives, sliding in and out during commutation by means of a hand-operated handle.

The body of the machine's electrical package is made in the form of a prefabricated structure, consisting of electrical insulating washers, fastened together by means of pins of a special shape. When the knives are inserted, the contact terminals enter the spring-loaded grooves of the switching mechanism. When the handle is turned by one quarter of a turn, the fixed and movable parts of the switch are closed with each other. Their course is limited by a special stop located on the cover of the device.

The disc switch, in contrast to the considered cam mechanism, works on a different principle. It turns on and off with one turn of the control knob strictly 90 degrees. The specificity of this device is the location of the control handle, which is always in one of two positions (this, in principle, distinguishes it from the cam version).

Due to the simplicity of the mechanism, as well as the comparative ease of switching, packet switches and switches are still widely used in the following areas:

- as input switches;

- to switch control chains;

- as a purely distribution switching device;

- in starting circuits of electric motors for various purposes (in ventilation systems, for example).

There are several types of batch machines designed for operation in a wide variety of climatic conditions, including explosion-proof design. They are installed in particularly humid rooms, as well as in technological niches and introductory panels provided for by the development project.

Advantages and disadvantages

The attractiveness of switching devices is explained by a number of their advantages:

- compactness, which greatly simplifies the installation of the device and ease of use;

- fast extinguishing of the electric arc in 380V three-phase electric bags, explained by the rational design of the working chamber;

- ease of maintenance;

- mechanical stability;

- versatility of application.

The packers are capable of operating in conditions of strong temperature changes (in the range from -40 to 70 degrees). Products with a sealed body are reliably protected from dust and moisture.

The disadvantages include a small resource in terms of the number of maximum switchings and complete unfitness for repair. In the event of a breakdown, they are simply replaced with new products.

Updated analogs of the device

The outdated models of packers installed in electrical panels are being replaced everywhere by more convenient and reliable automatic machines. This is due to the fact that the requirements for the efficiency of such devices have changed. They must combine the capabilities of RCDs, simple and differential circuit breakers, and sometimes contactors when installed in 380 volt power circuits. Before connecting a protective device, you will need to familiarize yourself with the features of each of the designated functions.

RCD and automatic machine

When operating in RCD mode, the device guarantees protection of a person from high voltage shock. It reacts to the differential current that occurs when leaks appear in emergency circuits, which can lead to a short circuit, as well as a fire in the wiring.In a dangerous situation, the device simply cuts off the electrical network and prevents further development of unwanted events. To control its performance, there is a special button on the body with the designation "Test".

Automatic bagging machines today have completely replaced old-style switches. They perform similar functions, but are more convenient to use, durable and have increased wear resistance. When used correctly, they are able to selectively perform their functions, guaranteeing quick disconnection of a dangerous circuit with a minimum time delay.

Difautomat

Difavtomat is a universal device that combines the functions of an RCD and a conventional AV. It completely replaces circuit breakers installed not only in household power grids, but also in enterprises. In other words, a difavtomat is "2 devices in one", united in a common body. This device does both functions well with its small footprint and easy handling.

Contactor (powerful e / m relay)

Devices such as contactors are used when it is necessary to switch electrical circuits with currents up to hundreds of Amperes. A feature of these devices is the ability to control switching modes at remote distances. Electromagnetic relays do not react to leakage currents, since they are designed only for their nominal values. This makes them significantly different from conventional circuit breakers. Such devices are traditionally installed in elevator mechanisms, electric vehicles, and industrial equipment.

In modern conditions, it makes no sense to install outdated models of packet switches in place of the input machines. For these purposes, reliable and easy-to-use automatic devices with increased functionality are better suited. However, this brand of switching devices is indispensable in other places where it is required to manually remove the power supply during installation operations, for example.