When installing electrical wiring in an apartment, private house, cottage, administrative or industrial building, a prerequisite is the use of a box for automatic machines - a special switchboard in which circuit breakers, a meter and other protective devices will be located.

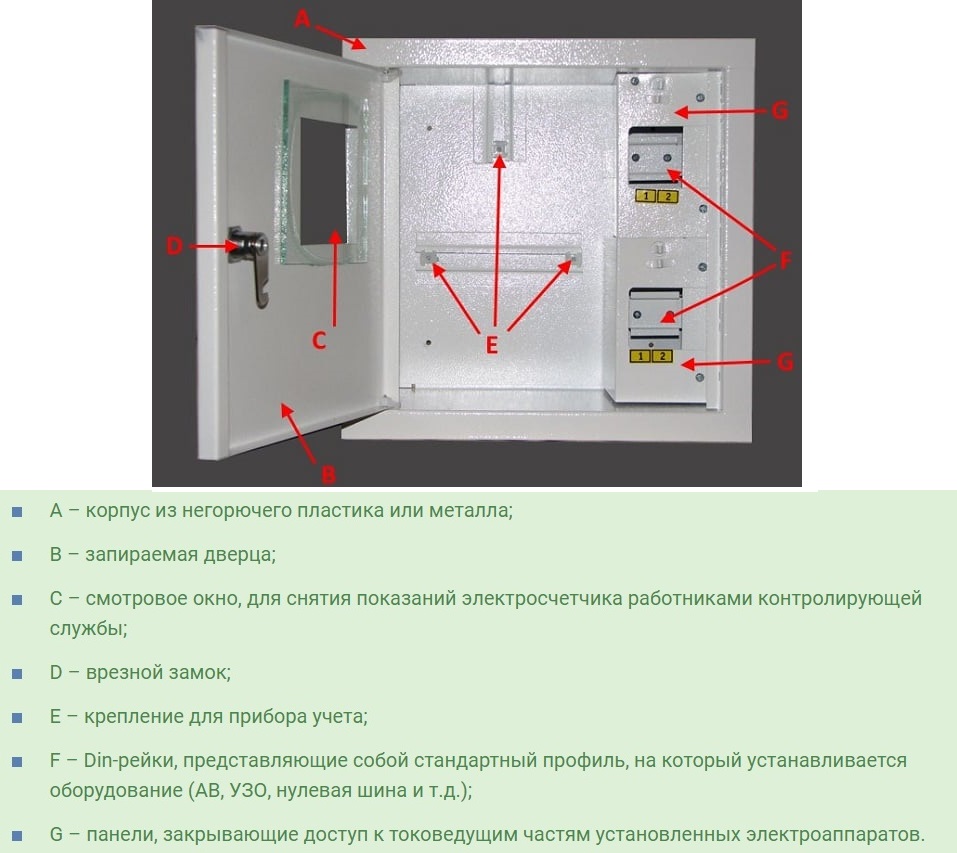

Electrical board design

The simplest and most common box for machines consists of the following parts:

- Front panel (cover) - equipped with an opening transparent door and breakable sections for installing a certain number of machines and other devices. Attaches to the main body with 4 plastic screws. Depending on the model, the door can be equipped with either a simple self-locking push catch or a lock with a core and a set of keys.

- The case is the bulk main part of the box, inside which all machines, RCDs, and a counter will be located.

- DIN rail - a metal bar for fastening machines and other devices in a box.

- 2 buses for connecting neutral and grounding conductors.

Also, the set of distribution boards includes special dowels for fixing the box to the wall, a support (protective casing, holder) for zero and grounding buses.

In some models, DIN rails are fixed on special removable holders that allow you to adjust the height of its installation relative to the front panel.

Assignment of boxes for machines

In addition to circuit breakers, the box is used for the installation and compact placement of such protective and monitoring devices:

- RCDs (residual current devices);

- electronic counters;

- differential automata;

- introductory machines.

In addition to these devices, the bundled ground bus (combs) and neutral wire are also installed in the box.

Types of equipment in accordance with GOST

According to the latest version of GOST 32395-2013, depending on the location, boxes for machines are of two main types:

- Apartment - boxes with protective devices, switches and counters. Installed in common corridors uniting several apartments. They serve to protect against voltage surges in electrical networks of these residential premises, as well as to account for the amount of electricity consumed.

- Floor (general) - distribution boxes with installed protective devices and switches designed to protect against voltage surges and, if necessary, disconnect all consumers on one floor.

In addition to this classification, boxes for electrical machines are divided into 2 types depending on the method of their installation:

- Built-in (internal) - installed in wall niches, so they take up little space and fit well into almost any interior.

- Hinged (outdoor) - fixed on the wall itself. They take up much more space than built-in ones, as a result of which they have a less attractive appearance.

Models built into the walls are more popular, as they look more aesthetically pleasing and neat, and are easy to maintain.Hinged ones are most often used in cases where it is not possible to cut a niche in the wall or the surface on which the junction box is placed is much smaller in width (for example, when mounting a metal box on a pole).

Box Specifications

The technical characteristics of the junction boxes include the class of electrical insulation and protection, the type of material from which the case and other components are made, the overall dimensions of the box and the number of modules that can be accommodated in it.

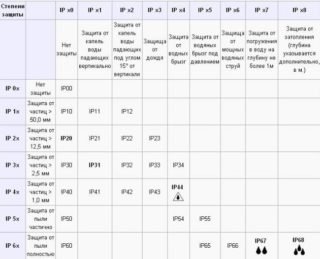

Electrical insulation and protection class

All modern models of boxes have class II electrical insulation, so they can be installed in rooms with humidity up to 85% and in outdoor conditions.

In terms of the degree of protection against the penetration of mechanical particles and moisture, the boxes can belong to the following classes:

- IP30 - installed inside residential premises. Provide protection to the devices inside from mechanical particles larger than 2.5 mm. Such a box does not protect against moisture drops.

- IP40 is also a box installed inside residential premises, which protects the devices placed inside it from mechanical particles larger than 1 mm, while not providing protection against dripping moisture.

- IP55 is a universal junction box that can be installed inside living quarters, bathrooms, outdoors. Fully protected against dust and water jets.

In most cases, junction boxes of the first two classes are used - they are more accessible and at the same time provide the necessary protection for residential premises against dust and large particles. Boxes of class IP 55 are used less often - they have a high cost and do not always justify themselves when installed in rooms with low humidity.

Material of construction of the case and parts

The following materials are used for the manufacture of the box body and lid:

- Polymers - fire resistant polystyrene, ABS plastics in various colors (from white to brown or even red).

- Metal - sheet steel up to 1.5 mm thick.

The busbars for grounding and neutral conductors are made of high quality copper. The height-adjustable DIN rails are made of polyphenylene oxide.

Number of rows and modules

The number of rows in modern models of boxes for machines varies from 1 to 4, installed modules (machines, switches and other devices) from 2 to 56-60 pieces.

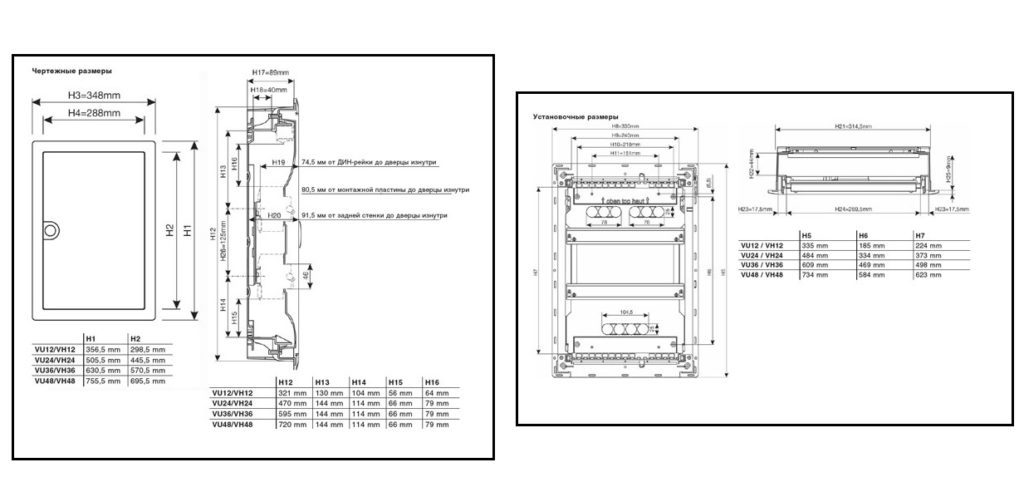

Nominal parameters of shields

The box for electrical machines, depending on the number of devices built into it, can have the following overall dimensions:

- height - from 125 to 714 mm;

- depth - from 58 to 88 mm;

- width - from 44 to 359 mm.

The maximum weight of plastic junction boxes is 1.5-2.0 kg, metal ones - 4.6 kg. Boxes are used in networks with voltages up to 400 V with amperage from 5-6 to 63 A.

Expert advice on selection and assembly

When installing and installing various devices inside the box, the following tips from craftsmen and experienced electricians will be useful:

- The selected box for circuit breakers must have a "reserve" in the number of modules so that in the future, when connecting new equipment, you do not have to buy another box.

- A box for an introductory machine with a special seal can be installed inside a spacious flap, always placing it in front of the meter, and not after it. This will de-energize the meter and remove it for repair or verification. Removal of the seal and re-sealing of the meter is performed by the controllers of the power supply company.

In the absence of skills in the installation and assembly of junction boxes, it is better to entrust the work to experienced craftsmen. Despite the cost, it will be cheaper than fire or fire damage if the cabinet and safety devices are not properly installed.