Equipotential bonding is one of the most important requirements for the regular use of electrical appliances in residential premises. It is characterized by a decrease in the potential difference between the surface of the floor covering, the ground and grounded metal parts of electrical appliances. Potentials can be equalized by laying special conductors on the surface, which are connected to ground. This circuit is simple but effective as it reduces the touch voltage when the insulation is damaged.

Why you need to equalize potentials

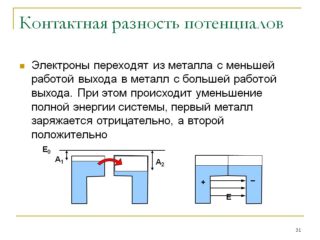

Before you figure out what a PCE is in electrics, you need to understand concepts such as electrical potential and current. You can get acquainted with their physical properties using the example of an ordinary conductor. When he is at rest, his inner cavity is uniformly filled with all charged particles, they are negative and positive.

If we talk about every object that generates current, then one of its poles is full of electrons, and the other is lacking. When a conductor is connected to it, the electrons inside will begin to rotate in the opposite direction until the balance is reached. This movement is called electric current, and the difference in electrons is negative and positive electric potential.

The current is constant if, with a constant potential difference, the movement of electrons is directed in one direction. If the state is characterized by a constant change in the direction of the electrons, the current is called alternating.

The home network is characterized by the fact that such changes occur at intervals of 50 seconds. Hence it follows that the frequency of the alternating current is 50 Hz. The surface of all conductors through which electric current flows must be insulated and located in places where there is no contact with surrounding objects. This applies to all parts made of metal, for example, metal parts and structures that have zero electrical potential - no current should flow through them. With correct and correct work, they perform the assigned tasks autonomously and do not pose a potential threat to the health and life of household members.

Causes and danger

- the formation of static electricity;

- regular exposure to the subject of stray currents;

- high atmospheric pressure (such phenomena are often observed when there is a thunderstorm outside).

- structural changes in metal structures and parts.

A particular danger is the leakage of electric currents from the wires of the wiring, a short circuit on the housings of household appliances and other electrical appliances. Most often, this phenomenon can be found in the bathroom - you can get an electric shock by touching a wet faucet or pipe. This happens most often due to the destruction of the insulating layer or violation of the integrity of the wires. This and similar situations can lead to negative consequences, for example:

- A person stands on the floor and at this moment touches a battery or pipe, which, as it turns out later, is energized.Each surface that a person touches has a different potential, therefore, the current begins to pass through his body. The result is electrical injuries of varying severity.

- If the floor surface was not insulated, but grounded, the person would also inevitably be electrocuted.

In order to prevent the occurrence of dangerous situations in the future, all equipment and devices that should not be energized should be connected in a single circuit. In this case, during the development of emergency situations, all surfaces will have the same electrical potential.

Types of equipotential bonding boxes (KUP) and their device

- The main one is BPCS.

- Additional - DSPP.

Each has its own technical features, advantages and disadvantages, so you should familiarize yourself with them in more detail.

Potential control main box

This equipotential bonding box is considered the main one. It is a contour that combines the following work elements:

- grounding box;

- lightning protection system;

- GZSH - the main grounding bus (it is required to be mounted at the entrance to the structure);

- water pipes made of metal (cold and hot water supply);

- ventilation system box;

- metal parts of the reinforcement of a residential building.

Several decades ago, household members did not know anything about such a problem as a potential difference. The reason for its appearance was the installation of plastic pipes that conduct an electric current, which leads to an open circuit.

DSPP box

- ventilation system box;

- shower enclosure or bath;

- sewer system;

- towel dryer;

- heating, water supply and gas pipes.

Each part of the additional equipotential bonding system is connected by a separate wire to a core made of copper. Its second end is connected to the DSPC.

The principle of operation and installation of the control unit

To prevent the formation of potential differences, a control box is installed in the rooms. The principle of operation of the device lies in the parallel connection of all structures made of metal. The KUP box unites all conductive objects into a single circuit.

Installing a potential equalization system at home is not difficult. It got the name - the local system. It is recommended to mount such a structure during repairs in an apartment, since it is required to lead a wire from the switchboard to the control unit under the floors.

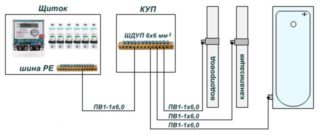

To install the unit, you will need the following tools and materials:

- Fasteners - fixing lugs, clamps, bolts. They are used to connect the wires of the entire circuit.

- Terminal box with a copper busbar (ШДСП).

- Copper single core wires. The cross-sectional area of such cables should fluctuate within 2.5 - 6 mm2, grade - PV1.

If all the necessary equipment has been prepared, you can proceed with the installation. They preliminarily draw up a wiring diagram in order to correctly equalize the potentials. Also schematically shown are the locations of the cables from the box to the earthing bus in the switchboard.

The next stage is preparation for connecting the communications themselves. The contact points are cleaned until a characteristic metallic sheen is formed. This is important as it provides a reliable connection. In an abnormal, emergency situation, the potential equalization system will not fail.

Lead cables to each part of the chain. All conductors are led into the box and make a reliable connection to the bus.

The terminal box, installed in a room with high humidity, must have a housing protection degree of at least IP54.

The best option is to install the system at the stage of building construction, however, there are restrictions on its use:

- It is forbidden to install in houses where a TN-C earthing system with a PEN conductor is installed.

- If plastic pipes made of polyethylene are installed at home, they will break the circuit and cause an electric shock.

The cross-sectional area of the conductor used must be at least the recommended value.

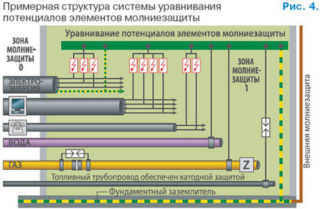

Lightning protection system in equipotential bonding

To prevent uncontrolled voltage surges and short circuits in the event of a lightning strike, it is required to connect all electrical devices, lightning protection, grounding, metal objects with the potential equalization system. All loop conductors are connected using an equalizing bar. Large building structures are usually equipped with several of these oversized tires. Moreover, they must be connected to each other.

The lightning protection potential equalization box must be installed at the entrance to the structure, as well as in places where it is not possible to maintain safe distances, for example, in the basement or at the same level with the ground. In a building made of concrete or with a metal frame, the leveling of the system must be carried out exclusively at ground level. In tall buildings, such systems are installed at intervals of 20 meters.