Cam switches are becoming more and more common electrical mechanisms that use a clock frequency to switch electrical circuits. They are actively used to measure various quantities in powerful motors, take part in the control of various electrical systems, they are equipped with transformers.

General information about the cam switch

Cam switches are special electrical devices that switch both direct and alternating currents in electrical circuits. Such devices are used in low-voltage circuits, as well as in circuits with voltages up to 500 V, for alternating and direct current.

The products include high-quality insulating and conductive raw materials, and the results of successful experiments in the creation of modern technology and the knowledge gained in the development of such equipment are also involved in the production. The characteristic features of cam devices are compact dimensions, high resistance to short-term loads in the chain. They also have excellent switching characteristics. To protect them in the electrical circuit from short-circuit current, it is required to additionally install fuses equipped with fuse-links.

Specifications

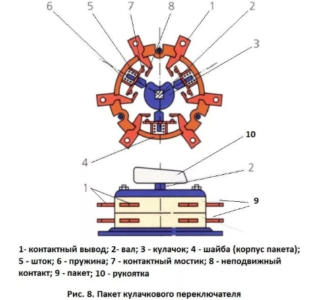

The location of the cams and contacts is a circuit program, its main task is to assemble a specific wiring diagram. They are installed inside a plastic enclosure that also contains melamine.

The advantage of the housing material is its resistance to eddy currents and electric arcs. A simple yet efficient design allows a large number of contacts to be turned on and off simultaneously. This is achieved due to the fact that the cam of one working segment is mechanically connected to other units.

To increase the wear resistance and switching characteristics in the device, the contacts are made not of copper, but of silver. Another advantage of the material is that silver can withstand an electric arc. Also, the device is equipped with a locking mechanism of the drive, without the participation of which the switch will not be able to be fixed in a given direction, therefore, the cam switch will no longer be able to cope with the tasks set.

It is worth mentioning the drive limiters. Its purpose is to hold the switch in the extreme position. The device shaft or drive is an ordinary square bar. For optimal contact switching and reliable operation, it must be made of high-quality metal so that the part can withstand the load when rotating. This point is very important in those industries where it is required to control the electric motors. For the convenience of control and switching modes, a special handle is used, made of a special insulating substance.

Types of cam switches

In hardware stores, there is a fairly large assortment of cam switches in different forms.

- Two-terminal equipment that is required for the operation of pulse-type transformers. The peculiarity of such a switch is that the control device is based on a conventional adapter. Characteristic features: the output voltage reaches 3 V; equipped with an insulator sheath; the current is controlled by the modulator power; module size - 10 mV; capable of withstanding an overload of up to 5 A. It must not be used when working with voltmeters.

- 3-position or 3-position cam switch. Devices that can be used with voltmeters. Characteristic features: small size; maximum voltage indicators reach 20 V; connections are on the back of the structure; the device is equipped with additional stabilizers.

- Equipment used in transformers. Characteristic features of this type of cam switches: some modifications are equipped with tetrodes; 15-volt installations have a modulator sensitivity of no more than 40 mV; current transmission reaches 6 microns.

- Switching equipment that is additionally equipped with an amplifier. They are actively used in measuring instruments. Device characteristics: connection is provided using adapters; equipped with filters of different types; contacts are located on the back of the case; the maximum load indicators are 12 A; the value of the current conduction 12 microns Do not use this type with pulse transformers.

In order to select the most suitable cam switch, a more detailed study of specific models is required. To prevent the purchase of low-quality goods or fakes from well-known manufacturers, you need to make purchases in specialized stores or from official representatives.

Operating principle

The operation of the cam switch is based on the activation of the contact group by rotating the device drive. Mechanical rotation of the built-in handle causes the actuator to rotate around its axis, which drives the same cams.

Active cams close the required contact group. To analyze a working group of contacts, you need to follow the inclusion diagram, the principle of its preparation is based on the required connection diagram. If the actuator is in the desired position, with the help of a special latching mechanism, the switch becomes stationary, the predetermined circuit begins to perform its work. To return to the zero position, the handle must be turned again.

According to the principle of operation, cam switches are divided into manual and equipped with an automatic return of the handle to its original position.

Purpose and scope

The device is actively used for the following purposes:

- Turning on and off the drive of the working segment of the section disconnector, which the transformer substations are equipped with.

- Control of complex structures and entire systems that are driven by single-phase and three-phase motors, changing the direction of a rotary element, for connecting the windings of AC motors.

- Switching modes of operation of heating elements or equipment as a whole is carried out.

- Alarm and control for operational purposes.

- Ensuring the required connection of resistance elements.

- In the form of a switch for operating positions in an electric welding machine.

The device is quite multifunctional, therefore, it has found application not only in industrial production, but also in everyday life, power supply and water supply facilities. Also, the cam switch is actively used in agriculture to control equipment.If you try, with the help of such switches, you can organize a bypass connection.

Cam switches have a fairly extensive list of advantageous features. The quality and safety of switching, as well as resistance to high loads, deserve special attention.

For the manufacture of equipment, high-quality, strong and wear-resistant materials are used, which explains the considerable cost of the equipment. The ease of use and maintenance is also a welcome addition to the regular operation of the cam switch.

Developers devote a lot of time, effort and money to the invention of such equipment, but designed to operate in adverse conditions, for example, in a humid environment or at critical temperature points (extremely low or high temperatures). It is also possible to make custom cam switches, taking into account the goals and objectives of the customer.