During repair, modernization or installation of electrical wiring, special attention is paid to the quality of the connection of conductive conductors. A reliable soldered connection is the key to the safe operation of electrical lines and household appliances. To fix the solder well, you need to pre-irradiate the wires, the essence of the procedure is to cover the surface with tin.

Why is tinning of wires so important?

Before tinning the wire, you need to find out why this procedure is so necessary. Copper and aluminum, when interacting with oxygen, oxidize, forming an oxide film on their surface, which impairs conductivity and increases resistance. Tinning the wires avoids this. Tinned wires with lead-tin solders, their advantage is long service life, safety and reliability.

Tinning is also used during soldering, for example, when connecting LED strips to a power supply. If the veins of the lighting device are not pre-irradiated, over time all the wiring will fall off.

Servicing the wire with a soldering iron

To do the job well, it is important to confidently own a soldering iron. If there are no established skills, it will not be possible to tin and solder the wire.

There are different models of soldering irons, each with their own technical characteristics - power, dimensions, etc. It is recommended that a novice craftsman give preference to soldering stations, where it is possible to regulate the heating temperature on their own.

It is advisable to purchase an expensive device, since the process will take less time and the work will be done with joy.

Required tools

Installation, modernization, repair and maintenance of wires is troublesome, but not difficult. To reduce the time spent, all the necessary tools and consumables are pre-prepared for work. The list looks like this:

- consumables include solder and flux;

- sharp knife;

- soldering station or soldering iron;

- technical or medical tweezers;

- ordinary pliers.

You can use not a well-sharpened knife, but special pliers that allow you to remove the entire insulating layer in several movements. But their cost is quite high, so many people use a knife or scalpel.

In each case, a certain solder and flux composition for cables is required, this must be taken into account.

Procedure

- Using a special tool, knife or scalpel, remove the insulating layer from the wires that need to be connected.

- After removing the insulating material, strip the conductors to a characteristic shine. You can use a knife or sandpaper to do this. If the work is to be done not with a cast core, but with a stranded wire, each wire is fluffed and stripped separately.

- A soldering iron is plugged into the socket and is cleaned of all the dirt that he likes to collect, especially old solder and dust. It is recommended to use a small emery paper when cleaning the soldering iron conductor.

- You want to warm up the tip of the wire.This can be done with a soldering iron, gas torch, or regular lighter.

- When the soldering iron has warmed up to operating temperature, solder and rosin are touching its soldering iron. The work surface should be abundantly covered with melted tin.

- The next step is to touch the copper conductor with a hot soldering iron. The solder must be evenly distributed over the conductor. Pliers and tweezers are used to apply the solder.

- Upon completion of the work, the cable or wire is carefully examined. The work surface must be completely and evenly covered with solder. There should be no empty cavities or accumulations of material. If deficiencies are found in the work, the procedure is started again.

If the work is to be done with very thin wires, it is better not to use rosin, since it is very difficult to calculate the exact amount of the substance. Soldering acid is suitable as an analogue. You can process the tip of the guidewire with an ordinary brush. After that, you can start applying the solder. This method cannot be called more reliable, but with these types of wiring, it cannot be otherwise.

Ways of processing wires

There are several ways of tinning. Some craftsmen prefer the method, the essence of which is to press the wires with a soldering iron to a wooden flat surface.

When heated, gases are released from the wood, which play the role of a flux, helping to remove oxides on the metal.

It is possible to remove the oxide film on the surface of the conductive cores more efficiently with the help of aspirin. During operation, the tablet is placed under the wires. When heated, gases are released from acetylsalicylic acid, enveloping the junction, displacing impurities from them that adversely affect the quality of the compound. This method, which is simple and inexpensive to implement, provides high-quality tinning.

There is another way to prepare multicore cables and wires, in which the copper base is coated with enamel. It is preferable to use a small piece of PVC material as a substrate. Under thermal exposure, polyvinyl chloride begins to actively release hydrogen chloride, which effectively destroys the oxide layer.

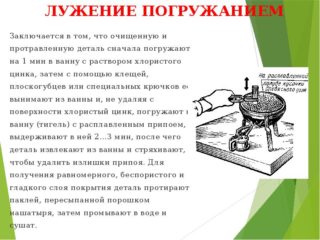

Tinning by dipping

There is a special device - a crucible, in which small pieces of tin are placed. There they heat up, resulting in a melt of metal. The end of the wire is preliminarily immersed in rosin or other grades of flux, and then into the container of the crucible. This approach ensures complete and even distribution of substances at the cutting site.

This method can only be used with fully tinned wires. Diving already has a completely different scale, and is carried out in an industrial environment. The process is realized using a special coil with wound wire. First, the entire copper surface is manually treated with stiff brushes, and their bristles are preliminarily treated with liquid zinc chloride. The dissolved flux is obtained from a mixture of technical hydrochloric acid and zinc.

Next, the wire from the skein is slowly unwound and dipped into a container filled with dissolved tin. The uniformity of the coating is ensured by secondary processing of the cable or large diameter wire with rubber brushes. Finally, the cable is immersed in a container of cold water and brushed again. After that, wires and cables are wound and packaged for further sale in hardware stores.