In order for electrical devices to work smoothly and for a long time, it is important to ensure reliable contact and tight fit of the cable to the electrical network. For this purpose, use special ferrules for wires designed for crimping. For high-quality performance of work, you need to familiarize yourself with the features of the event and prepare a special tool.

Purpose and scope

The main task of lugs is to provide reliable contact between multiple conductors, a bus and a wire, as well as a clamp and a wire. They are also used to simplify the installation work associated with electrical equipment when performing any technological operations.

Cable lugs serve as a quality analogue of various twists and all types of homemade connections that are still very common. This inexpensive and easy-to-use device serves as a guarantor of high-quality fixation of the wire inside the sleeve.

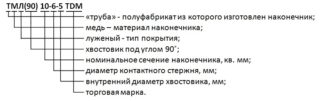

Wire lugs marking

Product labeling differs depending on the manufacturer that specializes in the production of handpieces. Some of them prefer full alphanumeric labeling, while others use only numerical values.

Marking and design features depend on the standard from which it was manufactured. The most popular and popular are domestic and European standards such as GOST 23981-80, TU and din.

Letter designations:

- Tip types: sleeve - G, ring - K, tubular - T, pin - Sh.

- Construction: split - R, dad - P, mom - M.

- Optional equipment with vinyl insulation: combination of VI or V.

The digital designation includes the cross-section and area of the lug, the diameter of the hole intended for connection with the cable core. It may also contain information about the size of the bolt hole.

Execution options

By design, the tips are divided into screw and those requiring crimping. The peculiarity of the first is that the cable is clamped with bolts. It is preferable to use the second type if you have to work with single-core wires. At home and at home, the second option is more often used, since they are also suitable for flexible multicore cable.

Also, parts are divided into several types depending on the connection method: angular, fork and straight, ring, sleeve.

Selection of lugs for crimping wires

- One of the most important aspects is the cable size.If it is larger than the diameter of the tip hole, the cable simply will not go into the sleeve; if less, the connection will not be tight.

- Hardware connection methods may also vary. The wiring part must be used if direct connection is not possible.

To get a good connection, you should take into account the flexibility of the ferrules.

Basic rules for crimping

In order to perform high-quality crimping of wires using lugs, it is important to observe the following rules and recommendations:

- Choose the right wiring part.

- Strip the wires thoroughly.

- For high-quality crimping, use special equipment.

- Choose the right matrix.

An important factor on which the outcome depends is strict adherence to the sequence of actions when crimping.

In order not to damage the connecting elements, it is necessary to additionally set the diameter on the pressing tongs.

Pin tips NShVI

NSHVI are plug-type electrical parts of the sleeve type. They are made of electrolytic copper, and the back is covered with insulating material. The material is treated with galvanic tinning.

In industry and at home, such parts are used for crimping cables with a cross section of at least 0.25 mm2. In comparison with analogs, this type of structure has many advantages, the main one being a significant saving in time spent on crimping.

Crimping multi-core wire NSHVI is carried out as follows:

- Analyze the cross-sectional area of the wire and select the correct ferrule brand. It is important that the veins enter freely from the side of the skirt.

- It is recommended to purchase liners with a small margin. For example, a 1.25 mm wire should be crimped with a sleeve from 1.5 mm sq, and the cross-section of the skirt will be no more than 2.5 mm sq.

For high-quality performance of work, it is recommended to use special pressing tongs or hydraulic tongs, tools of the PK1 or PK1M brand.

Tips are used not only for the correct and long-term operation of electrical devices, but also for safety reasons. Loose connections can cause a short circuit and fire, resulting in great damage to health and property.