Power cables are used to provide uninterrupted power supply to industrial and residential facilities. One of the important tasks is to minimize electricity losses during its transportation. There are many different types of cable products. For the operation of electrical and electronic devices, copper wire is often used.

Advantages and disadvantages of copper

Copper is widely used to make wires. The only competitor is fiber optics. According to some characteristics, it is second only to silver. The following advantages of copper wire products can be noted:

- high conductivity and heat resistance;

- relatively low resistance;

- strength at the same time as plasticity and flexibility;

- corrosion resistance, no oxidation.

The disadvantage of copper products is the high price. Also, copper cable products are heavier than aluminum ones. This pays off completely with a long service life.

Varieties of products

The range of the modern cable industry includes wires, cables with metallic conductive conductors, cords, tapes and other products. The main types of electrical wiring are network, through which information is transmitted, and power for the transmission of current. Depending on the purpose, there are the following types of wired products:

- actually, wires;

- power cables;

- products for telephone lines;

- computer;

- special-purpose wires.

There is a certain marking for their systematization. Products are delivered in the form of sections of various lengths, which are wound on a reel or coiled into a coil.

Copper wire and cable construction

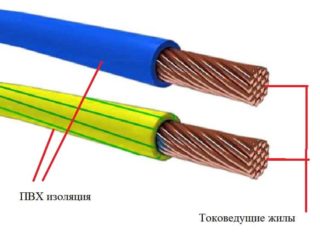

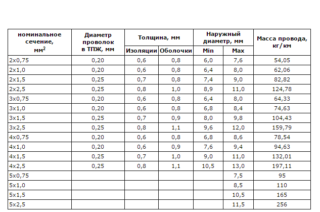

At first glance, these products do not differ from each other. But an electrical engineer can easily determine the type of product. Usually the name is indicated in the specification. TU and GOST contain different characteristics regarding cables and wires. They are divided by the thickness of the shell, insulation and the number of cores.

A wire consists of one or more wires, twisted together, with or without light tubular insulation. A cable, unlike a wire, has an outer sheath. Includes one or more insulated conductors. Can be used underwater, in the ground and other difficult conditions.

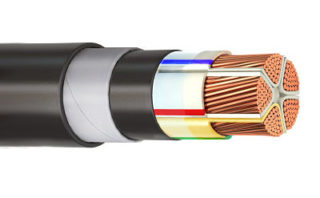

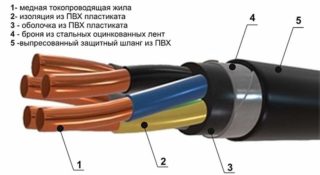

Any conductor includes the following elements:

- conductive cores;

- insulation with dielectric properties;

- shield to protect the conductor from electromagnetic interference;

- outer shell;

- protective elements for use in harsh conditions.

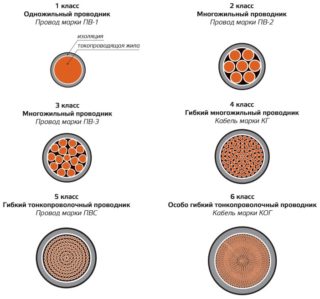

Products are divided into single-core rigid, which are used for hidden wiring, as well as multi-core, soft and plastic. Each stranded conductor is insulated separately, then they are enclosed in a common sheath. Such products can withstand repeated bends during operation.

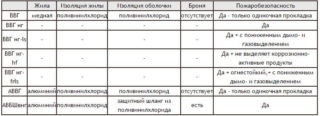

PVC, rubber, polyethylene, paper, fluoroplastic are used as insulating material. Also, the wire can be in silicone or enamelled.

Parameter overview

The main part of the cable structure is a metal conductor through which an electric current flows.The main parameters are DC resistance, bandwidth and cross-section. All conductors are produced according to regulatory documents that define the standard for direct current resistance of 1 km of conductor at 20 ° C (GOST 22483-77).

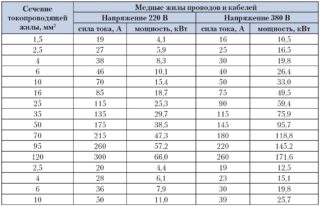

The permissible current for copper wires depends on the total power of consumers and the voltage of the electrical circuit. Calculated by the formula: I = P / V and is 10A per 1 mm2.

Wire class is calculated from 1 to 6, the higher the number, the more flexibility. For stationary fixed wiring, products of 1–2 class are used. Flexible wire with a class from 3 to 6 is suitable for mobile mechanisms.

According to the PUE, the most rational cross-section of copper wire in networks with household appliances is 1.5–2.5 mm2 for sockets, 0.75–1.5 mm2 is enough for lighting.

How to determine the cross section of a stranded wire

The safety and reliability of electrical wiring in the house depends on the correct choice of wire. Overloading leads to overheating of the conductors, the insulation melts, which leads to a short circuit and a fire.

The cross section is determined depending on the number of devices that will consume electricity. Therefore, it is necessary to calculate their total power used in the apartment. The result is multiplied by 0.75. There are tables where the ratio of the cross section to the current and power is indicated. The cross-section of a round cable can be determined by the formula:

S = π x r2, where π - 3.14; r2 is the radius squared. The radius of the conductors is measured with a caliper, the thinnest ones are measured with a micrometer.

If there are several wires in the core, their total cross-section is calculated. It should correspond to the calculated one, some change in the direction of increase from the standard is allowed. The indicator cannot be underestimated, since equipment can be added or replaced during operation. Therefore, when calculating, you need to apply a factor of 1.5.

Copper wire brands

Single-core mounting wire HB3 0.75 is mainly used for voltages up to 600 volts. Product of 3 class of flexibility with tinned copper conductor. PVC insulation. Designed for fixed inter-device mounting, connection of electrical and electronic devices.

PVA - flexible stranded assembly copper wire with vinyl double insulation. It has a circular cross-section (0.5–25 sq. Mm) from 2 to 5 cores. It is used to connect mobile electrical equipment, but can be used for household wiring.

Flexible copper stranded wire PUGV (PVZ), rated voltage 450 volts, cross-sectional area 6 mm2, insulation - PVC compound. Does not have an outer shell. They are used for laying low-voltage power lines; placement in concrete and brickwork, as well as under plaster is possible.

Winding wire is designed for winding coils of oscillatory circuits, chokes, transformers, electromagnetic relays. For insulation, enamel, fiber or combined materials are used. The main parameter is not the cross-section, but the diameter of the conductor. During the manufacture, a special production technology is used for especially thin conductors.

Copper cable brands

VVG - flexible stranded copper cable. One of the most common types for wiring both in an apartment and in production. It is used to connect any electrical equipment to the network. Consists of several copper conductors and external insulation. Each of the conductors is twisted in one plane, protected by a sheath and has its own color. Has non-combustible modifications - round VVGng, and flat VVGp.

NYM is a flame retardant PVC insulated cable. The number of cores is from 1 to 5, with a cross section from 1.5 to 16 mm2. Maximum strength and heat resistance is achieved by coated rubber filling the space between the conductors.

Flexible cable (KG) is used in conditions of constant voltage up to 660 V, or alternating voltage - 1000 V.Due to its flexibility, the product is used for portable equipment. For example, connecting the holder to the welding machine.

High-voltage copper cable PvPg is designed for a network from 6 to 10 kV. It has one core with a cross section from 50 to 800 mm2. Core insulation and outer sheath are made of XLPE with a protective shield. This makes it possible to lay the cable along the bottom of the reservoir, underground.

Copper cable applications

It is widely used in industrial plants where there is a risk of fire or explosion. Also, installation of internal wiring of residential and industrial premises, public buildings is carried out. Cabling and wiring products are distributed by application as follows:

- stationary laying underground;

- mobile connection;

- overhead power lines;

- in signaling and control networks with low currents;

- installation of household electrical wiring;

- special conditions using heat-resistant and flame-resistant conductors.

To transmit energy to distribution substations, a power armored cable with protection from a lead and metal sheath is used. Control cables with protection against mechanical damage are used to connect mechanisms and devices both outdoors and in tunnels and channels.

Different brands of copper wires and cables are designed to perform specific tasks. When repairing or building, the choice of cable products must be approached responsibly. The reliability and safety of power supply depends on this.