To ensure safety during power outages, special products are used - load break switches. They can disconnect the circuit remotely, manually or automatically. There are different types of switches that are suitable for a specific voltage and type of work.

Load break switch purpose

A load break switch is a switching device that is equipped with an arc chute and a drive for control. The electric drive can be muscular, spring-loaded, or with a remote shut-off solenoid. The main purpose of the device is to mechanically open or close a circuit in a section that is under load. Designed to disconnect emergency mode currents, which is why installation is permissible only if there is protection against overload and short circuit.

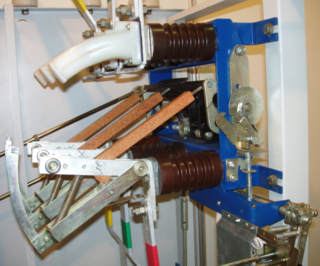

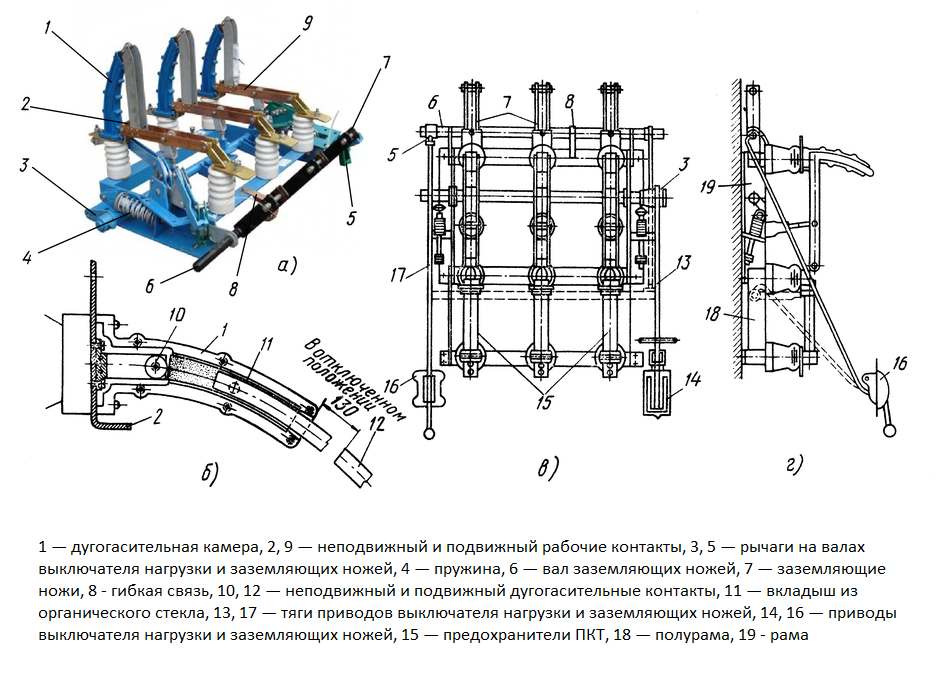

Any load switch consists of the following parts: a spring mechanism, power contacts, earthing knives, a disconnector with poles. The poles are housed in a frame. The main movable contact consists of 2 steel plates. A special copper contact is used to extinguish the arc. The mechanism is switched on and off using tensioned springs. A detailed description of the design will be considered using the example of the BHR 10/400 model. It includes:

- frame;

- support insulator;

- workers, grounding knives;

- holder with contacts;

- extinguishing chamber;

- insulating and locking rod;

- grounding shaft and working knives;

- lever arm;

- springs;

- internal gaskets.

When switched on, the movable contacts are located in the chamber. There are other contacts at the bottom that do the blanking. When disconnected, the main contacts are washed out, after which the arcing contacts. The arc passes into the chamber, where, under the influence of high temperatures, gas is released from the plexiglass. In this gas, the arc is extinguished in a few milliseconds.

- fixing method;

- rated current;

- additional options;

- equipment;

- design;

- Rated voltage.

The main area of use is networks of voltage class 6 kV and 10 kV. Such devices are used in power transformers, lifting machines, laundries, in public catering facilities, in car washes and other important objects operating under high voltage. Manufacturers use similar devices in their factories and factories, but more expensive and with more functionality.

Types of devices

Switches are divided according to the arc extinguishing method. There are the following types:

- Vacuum. They work on the properties of a vacuum in which the arc does not propagate.

- Autogas. The arc is extinguished by gases that are released at high temperatures in the chamber.

- Auto-pneumatic. The air is compressed and the arc is extinguished.

- Electromagnetic. The direction of the arc is changed by the action of the electromagnetic field.

- Electro-gas. Quenching takes place in the environment of electrical gas, consisting of sulfur hexafluoride.

By the number of poles, the following can be distinguished:

- single-pole;

- bipolar;

- three-pole devices.

By design, there are:

- thermal;

- semiconductor;

- electromagnetic;

- combined.

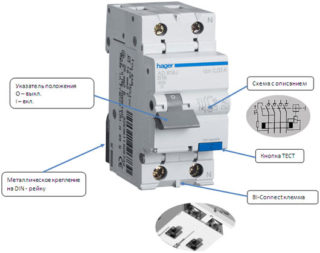

By the method of installation, the circuit breakers are classified into fixed and withdrawable.There are devices for indoor and outdoor installations. You can mount the devices on a DIN rail, wall or switchboard panel.

Load break switch marking

For example, the designation of a 10 kV load breaker VNRp 10 / 400-10zp stands for:

- B - switch;

- Н - load;

- Р - manual drive;

- P - built-in fuse;

- 10 - voltage 10 V;

- 400 - current 400 A;

- 10 - through current;

- З - presence of grounding knives;

- P - the location of the knives behind the fuse.

Other models are recorded in the same way.

Pros and cons

The main positive qualities of load break switches include:

- ease of manufacture and operation;

- the cost of the switch is lower than other similar products;

- convenience of switching on and off currents;

- overcurrent protection;

- there is a visible gap between the contacts;

- safety.

The disadvantages of load break switches include the ability to switch rated power. Operation with emergency mode currents is not carried out. Also, autogas-type switches have a short service life.

Differences from a circuit breaker

In the home, other devices are often used - automatic differential switches. They are installed on various household appliances to protect against power surges. They can de-energize the room if necessary, protect pantographs and wiring from the aggressive effects of high currents. Circuit breakers are not suitable for frequent shutdowns and shutdowns. This can lead to rapid wear of the module and burnout of the working resource, after which the device will have to be replaced. For such purposes, it is recommended to use modular load break switches. Input switches provide high safety of switchboards, uninterrupted power supply, convenience of circuit opening. The best option is to use the load switch and the machine at the same time. Then the safety of the power grid is increased.

The main difference from the machine is the impossibility of working in automatic mode. Switching requires external intervention - manual or remote. The machine is triggered when the current limit is reached. Also, devices may differ in labeling and appearance.

Connection rules

On power lines, the device is installed in front of the transformer. In residential buildings, the switch is installed in the switchboard or in another place for each apartment separately. In the apartment itself, switches are installed in front of the meter, but they can also be installed after the meter. Be sure to put the switch according to the scheme in front of other protective devices (plugs, automatic machines).

In factories, factories and other production areas, a switch is placed next to machines that may require an emergency shutdown.