Modern power supply systems are built on the basis of typical schemes, taking into account the methods of grounding the equipment connected to them. This is done in order to protect the end user, as well as the personnel working at electrical installations. When organizing modern networks, cables are traditionally used that include not only a phase conductor, but also a working zero N, as well as a protective PE conductor. In some cases, these two types of tires are combined into one common PEN-core. To understand their functional purpose, you first have to find out what the PE bus is and how the remaining conductors are color-coded.

Types of grounding systems

- T stands for ground (from the French "Terre" or ground).

- N is the connection to the transformer neutral.

- I means isolated.

- C - combining the functions of the working and protective neutral conductors ("common").

- S - separate use of these cores ("select").

According to PUE, TN-C means a system grounded to neutral with combined protective and working conductors.

The designation TN-C-S means that in some part of the power circuit, two conductors are laid together, and then they are separated according to their functional characteristics.

Classification of null tires

According to the functions performed, the zero buses that are part of the power supply system are divided into the following types:

- N - functional or working "zero", which is a conductor for load currents.

- PE is a specially laid protective "zero", which provides the possibility of organizing grounding at the receiving end in a convenient place.

- PEN is a conductor that combines the functions of both of these buses.

Each of the conductors in the diagrams is highlighted in a specific color (N - blue, PE - yellow-green, and PEN - their combination). They must be selected according to their cross-section, which should not be less than the same indicator for phase buses.

The specified decoding also allows you to understand why you need to separate the PEN conductor, what it is for, how you can equip the grounding on the consumer side.

Why split PEN into two

It makes sense to separate the PEN wire into PE and N conductors only if each of them is supposed to be used for its intended purpose. This can be done in the following cases:

- in a private (country) house, when a branch is made from the PE bus in the distribution board, used to organize local re-grounding;

- in a city apartment building, where the residents of the entrance have agreed to equip a common grounding loop on the street next to the entrance;

- a copper descent is carried out from the PE wire to a homemade ground loop.

To implement grounding with a homemade loop, you will need permission from the relevant energy services and coordination with housing and communal services.

When a jumper is placed in the driveway between the buses in city houses, there is no need to talk about a full-fledged grounding. The normative documentation on this matter provides a recommendation without a detailed explanation of the action of such "grounding".

Splitting options

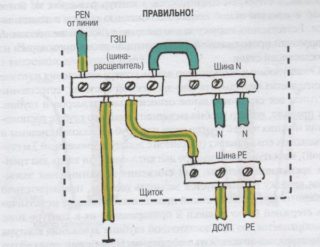

In the switchboard, where the PEN conductor is divided, the grounding is organized by the splitting method, but a jumper must be installed between N and PE. In this case, it is important that the ground bus is connected first, and only after that the connection of the working core is made out. In this situation, there are four options for connecting the PE wire:

- There is no jumper between it and the N conductor - the working zero contact and the grounding bus are not electrically connected. An RCD is also not installed in the protective circuit.

- There is a jumper between these terminals, but the RCD is not installed.

- PE for earth and N are shorted and an RCD is installed.

- There is no jumper, but there is an RCD.

In the first case, the "physics" of triggering protective circuits looks like this:

- The emergency phase falls on the body of the device.

- Then it goes to the ground bus.

- Further along it goes to the circuit of the transformer substation.

When considering the problem, it is important to take into account the resistance of the grounding circuit, usually not exceeding 20 ohms, taking into account the cross-section of the PE conductor in mm. square. In the event of an emergency, the short-circuit current will not be enough to turn off the input machine. The protective circuit will function until the damaged area on the receiving side is completely burnt out. This situation will not be able to bring tangible harm to a person, but the equipment will receive serious damage (the worst option is its ignition and fire).

There is a jumper, there is no RCD machine

In this case, the length of the supply line plays an important role (removal of the place of its damage from the input-distribution switchboard), which determines the resistance of the wire for draining the charge. In the event of an emergency short circuit of a phase to the body of the damaged equipment, the leakage current first enters the ground bus. Further, it has only two ways: part of the emergency electricity goes into the ground, and the other along the zero bus will trigger the machine at the input. In the considered situation, the jumper is used in case the AB did not work for some reason. But since the latter is practically impossible, it makes no difference whether it is there or not.

There is a jumper and an RCD is installed

Since all protective and working conductors have a certain resistance, in this case the RCD should operate normally. When a short circuit is formed on the case, the leakage current first goes to the RCD itself and only after that goes to the input of the residential building. Here, as in the previous case, it is divided into two parts: some part of the whole goes into the ground, and part through the jumper returns to the shield, turning off the introductory machine. However, business, as a rule, does not reach this point, since the RCD works much faster.

In this situation, the jumper does not really matter and is only a safety net just in case: if, by a strange coincidence, the RCD does not work.

There is no jumper and an RCD is installed

This will work in the same way as with a jumper. The only difference from the previous case is the lack of insurance in the event of an RCD failure, which is unlikely. If this nevertheless happened, the scheme will begin to work out according to the first of the considered options. In this case, the input device does not work until the short circuit to the case is transformed into a phase short circuit.

Typical phase splitting errors are associated with switching order violations. Do not connect the working conductor first and only after that connect the ground. Another common mistake is the unwillingness to install an RCD. In circuits with artificial splitting of the PEN conductor, the presence of a residual current device is mandatory.

Features of PEN conductor separation

In private houses and in city apartments, in order to prevent theft of electricity, representatives of the controlling organization have the right to require that the PEN wire be pulled to the meter. And only after the metering device they allow it to be divided into a protective PE bus and a working N.Such a connection does not contradict the requirements of the PUE, but the separation performed before the meter looks much more natural.

If you first make a separation, and then seal the input machine, there can be no objections from the representatives of Energosbyt and the inspectors.

Why guess and translate from a foreign letter designation of power distribution systems, when the decoding is given in the PUE (see clause 1.7.3). Moreover, the decoding of the letter T is different, depending on which letter T is in the abbreviation. From the same decoding, it can be understood that protective grounding of conductive electrical equipment housings is used only in IT and TT systems. And these are rarely used systems, especially the IT system. Basically, the TN system (TN-C, TN-C-S, TN-S) is used to power consumers. This is a system with a dead-grounded neutral of the transformer, where the conductive enclosures of electrical equipment are electrically connected to the dead-grounded neutral of the transformer, i.e. are zeroed (protective neutralization is performed; see PUE, p. 1.7.31). No one has yet canceled the protective neutralization, and its definition (what it is) is in the PUE. Conclusion: in TN systems, grounding of the enclosures is not used at all due to its uselessness (in case of insulation breakdown on the enclosure, it does not provide a safe current through a person). The main protection measure in TN systems is automatic power off, which is exactly what is provided by protective neutralization. An additional measure of protection is the use of an RCD. Therefore, there is no need to make any agreements with neighbors and grounding circuit devices, everything has already been done as it should. The only thing that can be done is to convert the TN-C system (who has one) to the TN-C-S system. But here, zeroing is also used.