The payment for the consumed electricity is carried out on the basis of the readings of the electric meters. Installation of devices is mandatory for all users and premises using the appropriate resource. There are several variants and models, which differ in the type of connection and the level of ultimate load. The connection of current transformers to a three-phase meter is carried out in different ways - the choice of a circuit depends on the room and voltage.

General requirements

Current transformers are equipment that are installed to reduce (convert) the indicator to a level normal for the operation of metering and control mechanisms (meters).

In other words, these devices (manufactured by Mercury, Lenelectro and others) are installed in areas with significant power in the case when direct connection is impossible due to high currents. Direct connection without a suitable fuse will burn the magnetic coils and damage the equipment.

As a rule, the masters of special installation and commissioning organizations are engaged in connecting current transformers. Large industries have separate workshops and laboratories.

First of all, an audit of the equipment is carried out - an external examination, a check for operability and maximum power. In addition, the tangent of the internal insulating wire and resistance is measured. Based on the data obtained, a connection diagram is selected, marking is done, the required number of holes is drilled.

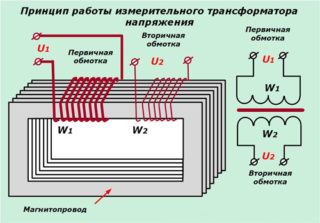

The principle of operation of instrument transformers

To reduce, a transformation ratio is used, due to which less electricity enters the secondary winding. This ensures the normal operation of the meter, and the output readings must be multiplied by the number of the coefficient in order to obtain the true value of the consumed voltage.

Thus, the transformer mechanism converts the high voltage at the input into an acceptable one for the meter. The equipment operates at a frequency of 50Hz and a current of 5A. for example, if the device has a load limit of 100A, the output is multiplied by 20 (100 divided by 5).

Thanks to adapters, meters are protected against voltage surges, short circuits, and overloads. Moreover, if a transformer burns out, it is easier to replace it than an electrical meter.

When connecting, it is worth considering some disadvantages. The most common option is that the starting value of the current of the meter is not taken into account. In this case, the counter simply will not be able to start working.

Incorrect connection polarity is another common mistake.There are two terminals at the input of the primary coil - one for phase L1, the other for load L2. The measuring coil for the coil is also equipped with two terminals (I1 and I2). The cable must be connected to the corresponding contacts, having previously calculated the maximum load.

If the microcontacts and wires are not connected correctly, a short circuit will occur. This can lead to failure of devices, fires.

Connection diagrams

Electrical meters and transformers are connected taking into account safety requirements and operating rules, as well as the features of the device itself. The minimum installation temperature is + 5˚ Celsius. Otherwise, the correct technical connection will not work - devices operating with voltage and currents do not tolerate low temperatures poorly.

If you need to connect a transformer outside in the cold season, you need to build a special cabinet - insulated and sealed. The device itself is usually installed at a height of 1-1.7 meters.

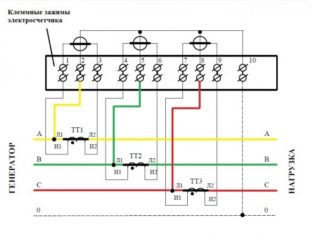

Installation of a meter with current transformers

It is not always possible to measure the consumed electricity through a meter connected to the power supply directly (to an outlet). In circuits with a voltage of 380 Volts and current limits of more than 100A - accordingly, the consumption rises to 60 kW - the installation of a measuring current transformer is required. Such a connection of the master is called indirect, but this method gives the most accurate data. In addition, there are two more methods:

- semi-indirect;

- star.

The first is used in industrial plants and large factories with a power consumption of more than 0.4 kW and a current of more than 100A.

The star schema, in turn, can be complete or incomplete. For a full star, devices with an even load distribution and symmetrical current flow are suitable. The transformer is installed on all phases and the relay winding is star-connected.

Incomplete - two-phase two-relay circuit with the formation of a part of a star. This circuit reacts quickly to short circuits (except for grounding), and it is also possible to install it on interphase shields.

Installing a multi-turn meter

A three-phase transformer connection meter is used in multi-wire networks. With multi-turn connections, the primary winding of the coil is replaced with a cable one. The device controls the flow of current through the secondary winding. Otherwise, the transformer works on the same principle as other types of equipment.

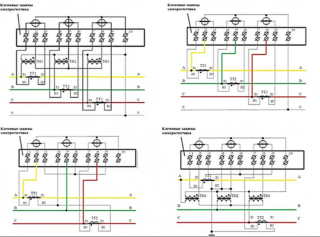

Ten-wire circuit

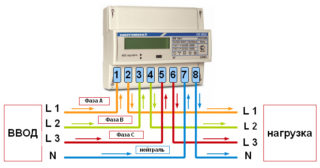

This connection method is suitable for use in powerful power circuits, the operation of which is provided by transformers. The galvanic decoupling is suitable for industrial and domestic needs and guarantees the safe operation of the equipment. Connection sequence by terminal (from first to last):

- phase, input (A);

- measuring circuit of the phase mechanism, input;

- measuring drive, output (A);

- terminal, phase, input;

- measuring circuit of the phase mechanism, output (V);

- phase, output (V);

- phase, input (C);

- loop, phase measurement - input.

The ten-wire circuit does not require disconnecting the power supply when replacing the meter and performing other work. Current circuits are reliably grounded, which eliminates the possibility of unwanted potential accumulation. Each phase is assembled independently of each other - in the event of a breakdown on one, the others will continue to work.

Seven-wire circuit

This connection scheme has a number of advantages and some disadvantages. Slightly different from ten-wire. It is convenient to work with the meter - there is no need to turn off the system completely when working with the panel, metering devices and transformers.

Thanks to the grounded current circuits, a dangerous potential does not accumulate at the outputs of the secondary windings, which often leads to short circuits and equipment burnout. A test box is connected to the mains, which allows the supply circuits to be disconnected safely.

The seven-wire method is one of the outdated, rarely used. Professional electricians do not recommend connecting in more modern ways.

Combined circuit diagram

This scheme is significantly different from the previous ones. Current transformers with combined circuits are connected through special jumpers (the path is obtained from L1 to L2).

Such a scheme for connecting the transformer to the meter does not comply with the updated safety rules in force today. Therefore, the use of combined chains is prohibited - both in production and in domestic conditions.

Other connection systems

In addition to those indicated, there are other schemes for connecting the meter to the transformer. The use of a test block in the connection - in accordance with clause 1.5.23 of the Electrical Installation Rules - is necessary when activating an exemplary meter. This is an additional equipment that allows shunting and disconnecting current circuits, activating meters without reducing the voltage load. Another point is the possibility of phase-by-phase readings.

The basis of the connection through the test box is a ten-wire circuit. The difference lies in the installation between the metering device and the transformer structure of the adapter block with the necessary protective and distribution functions.

Electricity metering with current transformers

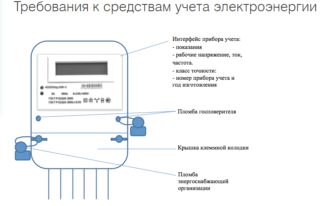

The electricity meter is the main device that shows the current energy consumption. Modern models give readings with greater accuracy, it is possible to configure several operating modes (for example, different metering in the daytime and at night - tariffs differ). Wizards recommend installing electronic equipment, not induction. The former are much more expensive, but reflect more accurate data.

The first thing they pay attention to is the number of phases in the network. Meters and transformers must have the same number of phases with the mains.

Three-phase devices are allowed on single-phase networks (not vice versa), but they are several times more expensive. A similar option is used if such a transformer is available.

An important point is the accuracy class of the transformers. Most of the facilities use 2.0 marking, which is enough for average production and household needs. For large-scale factories, substations, buildings, a higher class is needed - 1.0. The best option if the designation is supplemented with the letter S, which means the maximum accuracy of the device.

Electricity is a commodity for the use of which you must pay a certain fee. For different situations - industry, apartments, social facilities, others - separate tariffs are provided. To correctly pay for the consumed energy, correct and accurate metering is necessary.

If the meter is working properly, sealed by the relevant services, its readings are transferred to the organization with which the contract for the supply of electricity has been concluded. Further, in accordance with the electromere, the payment is calculated.

For large objects using high voltage, the installation of transformers is necessary. Otherwise, it will be impossible to use electricity meters and take readings, keep records of the consumed current.