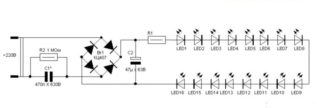

LED lamps are rapidly gaining popularity, due to the large number of advantages in comparison with analogues: efficiency and environmental friendliness of use, long service life. For use in everyday life, lighting devices are made with an operating voltage of 220 and 12 volts.

How to connect an LED lamp to 220V

The main advantage of such lamps in comparison with those operating from 12 volts is that they can be directly powered from a switch. As a result, additional financial costs are not required for the purchase of a power supply, and installation is not difficult. There are several ways to install LED lights:

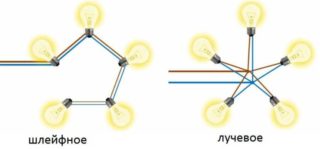

- serial connection;

- parallel;

- beam.

Each is used in different situations and has its own merits and demerits.

Consistent

Serial connection is used in the event that you need to save the length of the cable, and at the same time there are no special requirements for the room. Several double or triple wires are required for implementation. No more than six LED bulbs can be installed in one circuit, otherwise the brightness will be low. If one lamp fails, you will have to check the performance of each in order to eliminate the breakdown.

The connection itself shouldn't be difficult. A phase is conducted to the first luminaire from the switch, then the cable is pulled from the first switch to the next device. A zero is laid to the last luminaire, which comes from the junction box.

If an error is made in the circuit and the power supply is mixed with zero, the lamps will be under constant voltage, which is unsafe.

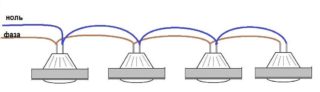

Parallel

Parallel connection is more practical and used more often. In the process of implementation, each lamp will give out the brightness, which is declared by the manufacturer. The only drawback that can be distinguished is the increased consumption of the conductor in comparison with the serial connection.

It is recommended to give preference to the VVG ng 2 * 1.5 or 3 * 1.5 cable. The designation indicates the presence of a PVC sheath - a high-quality insulating material. In the marking, the “ng” mark indicates the incombustibility of the model. If there are special requirements for the room, sometimes they use wires with an additional marking "ls", which means that a small amount of smoke is emitted during ignition.

To connect the luminaire, a cable is pulled from the junction box through the switch. It is alternately connected to each lamp. After the first lamp, the cable is cut and fed to the next until all devices are connected into one common system.

The advantage of the parallel connection is that even if one lamp fails, the circuit will be fully functional.

Beam

By its nature, the beam scheme refers to parallel connection, often used for chandeliers. The implementation principle consists in laying a cable to each lighting device individually. This method is the most time consuming and requires large financial costs due to the large amount of wire used.To save money, the cable from the switchboard is led to the center of the room and from there to each lamp. Further, single-core wires are supplied to the phase and zero, which are laid to the lamps.

At the design stage, it is important to decide how the conductors will be connected to a separate cable. If there are few lamps, a twist is enough. For safety reasons, it is reliably crimped with pliers and welded together with a soldering iron. There is an alternative to this method - to purchase terminals with a certain number of outputs. A connector is put on each core and only after the wires are pulled to the lighting fixtures.

The connection diagram of LED lamps in all cases has no fundamental differences.

Required tools

To connect lighting devices with your own hands, you will need the following working tools:

- a set of screwdrivers (flat and Phillips);

- a tool designed to strip wires (remove the insulating layer);

- pliers.

As practice shows, it takes no more than 10-15 minutes to assemble the device with your own hands.

Features of fixing and connecting ceiling lamps

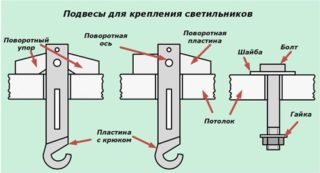

Depending on the appearance and design features, the installation of a particular model on the ceiling may differ. Algorithm for mounting the lighting fixture on the ceiling:

- At the place intended for the plafond, next to the wire outlet, holes are made for the mounting plate.

- Holes for fastening need to be made only in a solid base. If, when working with a punch drill, the mounting plate falls into the void, it is required to make holes in another place, respectively, move the lighting fixture.

- The mounting plate is securely fixed in one position.

- If the LED luminaire is not attached to a solid base, you must first take care of a secure attachment.

- The RCD or the electric meter is de-energized, the contacts of the lighting device are connected to the electrical line.

- The already connected lighting fixture is pushed onto the lug of the mounting plate and is securely fixed using the fastening elements.

- Transparent parts, for example, protective glass or a hood, are put on the fixed LED lamp.

The final stage is a mandatory check of the operability of lighting devices.

Precautions

During the performance of work, you need to remember to observe personal safety precautions.

It is necessary to de-energize the room and at the exit where work is to be done, check the voltage using an indicator screwdriver. It is also important to provide free space around the fixture. If you neglect this rule, the lamps will overheat, which will lead to their rapid failure or fire.