LED strip is actively used in the illumination of apartments. It is installed on ceilings, walls, furniture. It is easy and convenient to use such a device, besides, LEDs are safe and efficient. For these and many other reasons, people began to switch to diode lighting. LED strip does not require special skills when connecting and installing, but you still need to know some features.

LED strip device

LED strip is also called duralight. It is a flexible printed circuit board with LEDs and current limiting resistors. For ease of installation, there is an adhesive layer, with which you can install the tape on any flat surface, including in hard-to-reach places. You can turn it on like a regular lamp.

The LEDs installed on the board have different colors:

- white with different color temperatures;

- green;

- red;

- blue;

- yellow;

- multicolor.

Also, the tape has standard dimensions - thickness 2-3 mm, width 8-10 mm. The lengths vary, but the lights are usually sold in reels of 5 meters.

Criterias of choice

Before buying a tape, you need to decide in advance on the requirements. They will depend on the installation site, climatic conditions, and tasks. You should also decide on the budget that the buyer is willing to spend on the purchase of a lamp.

The main characteristics of the tape:

- The brightness of the glow.

- Type (monochrome, multicolor).

- Modes of operation.

- Number of LEDs per running meter.

- The quality of the LEDs, the type of crystal used.

- Dip or smd diodes. SMD LEDs are cheaper.

- Self-adhesive or not base.

- IP degree of protection against dust and moisture.

- Resistance to aggressive environmental influences.

When choosing, you need to decide in advance whether the tape will be additional illumination or a high brightness is required from it.

Benefits of LED strips

Lighting devices made of LEDs are distinguished by their positive qualities in comparison with classical light sources. Because of this, there is a transition to more profitable lamps.

The main advantages of duralight:

- Low power consumption.

- Duration of work. They can last from 5 to 13 years under the correct operating conditions.

- Laying along any path is ensured by the flexibility of the board.

- Possibility of cutting tape into smaller lengths.

- High efficiency.

- Lack of heating.

- Quick turn on.

- No flicker, which is negative for health. Ripples are noted only in low-quality cheap products of unknown origin.

- Resistant to network jumps.

- Lack of ultraviolet radiation.

- Wide range of colors.

- Fire safety.

- Environmental friendliness.

- Simplicity of styling.

- Manufacturer's warranty.

The disadvantage of LED products is the rather high cost of one product. But due to low energy costs, it quickly pays off.

Installation rules

- Niches of walls and ceilings. Then the tape is placed in a special box.

- The surface of the walls and ceilings inside the plastic corners.

- Behind the skirting boards on the ceiling.

In all these cases, the general installation requirements are the same.

- Connection is carried out only through a converter - a power supply that lowers the voltage to operating 12 or 24 V. It is forbidden to directly connect the duralight to a 220 V voltage source in the outlet.

- The tapes are secured and connected using specially selected connectors and connectors. Soldering is also possible.

- Do not bend the duralight and allow mechanical stress.

- You can cut the board only in specially marked places so as not to damage the conductive tracks. Otherwise, the duralight will not function. Likewise, you cannot damage tracks if you need to connect segments.

- It is imperative to pay attention to the IP protection class. For use in water, IP66 tapes are suitable, if it will be switched on outdoors, the class must be IP55.

- You can only attach the tape to a smooth and clean surface. Then the board will not be damaged and dirty.

The adhesive surface of the tape is not intended for repeated use. - The adhesive surface allows fixing the duralight only once. Therefore, it is recommended to choose and come up with a lighting system in advance so as not to waste money and ruin the lamp. You can draw a trajectory on the surface with a pencil to glue the device along it.

- If a piece of tape over 4A is used, it is better to connect the parts by soldering. This is more reliable than using connectors.

- It is recommended to connect no more than 5 meters of tape in series. Otherwise, the brightness of the LEDs will be lower and the system will overload.

- The power of the transformer - the power supply must be 20-30% higher than the total load.

It is recommended that you seek professional help when connecting the power supply. If the system is installed independently, it is imperative to observe safety precautions. Also, you cannot work with defective tape. In this case, it must be replaced under warranty.

Design guidelines

Duralight performs not only the function of illumination, but also a decorative one. You can get a winning interior design if you follow the advice of experts. With the help of tape, you can achieve various effects - for example, zoning the kitchen room or visually enlarging the ceilings.

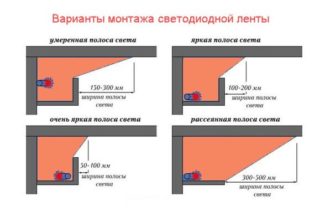

If you plan to create a multi-level system, the distance between the levels should be 20 cm. Otherwise, there is a risk of uneven distribution of light. The optimum depth is 2-3 cm.

If hinged glossy ceilings are used in the house, then it is better to refuse backlighting. Diodes on such a surface will be reflected as in a mirror.

When creating a luminaire layout, it is important not to forget about the convenience of access to them. If repairs are required, the technician should easily get to the broken part.

Fastening methods and installation

There are various ways to mount the tape to the ceiling.

- Installation in a plinth. This method has the most important advantage - the master does not need to redo the ceiling. The skirting board is mounted at a distance of 8-10 cm from the ceiling. You can glue the duralight on the skirting board itself after installing it. The tape is glued onto a special adhesive base.

- Installation in a plasterboard cornice. This method is more complicated, but it looks visually impressive.

Step-by-step instructions for installing duralight on the ceiling:

- Determination of the length of the tape, its characteristics. Buying a suitable profile.

- Purchase of a controller to control the backlight and brightness. The adjustment is carried out using the remote control.

- Purchase of special connectors. They depend on the type of duralight and the manufacturer. They differ in shape.

- The choice of the power supply.

- System assembly with sequential laying and gluing of LED filament.

- Connecting to the power supply.

The power supply is the most important part of the system. The choice depends on a number of characteristics that must first be dealt with.

Power supply selection

Power supplies differ in power - there are products from 6 to 400 watts. It is selected depending on the full load of the belt, taking into account a margin of 20-30%.

An example of calculating the power is as follows. There is a tape with a length of 5 m and a power of 9.4 W, for which the power supply is selected. The total tape load is 5 * 9.4 = 47 watts. The power supply must have a power of 47 * 1.25 = 58.75 W with a power reserve of 25%. The resulting value can be rounded up to 60 W - it is for this value that the unit is selected that should power the LED strip. The wrong choice threatens the lack of system performance.

Selecting a profile for installation

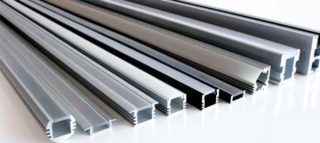

Mounting profiles differ in material and design. They are usually made from the following materials:

- Aluminum. It is a robust and versatile system that fits in with any décor. Used to quickly and easily implement a lighting system. Good heat dissipation.

- Plastic. The plastic box is made of high-quality and reliable material that is resistant to temperature surges, increased moisture, and mechanical stress. Sometimes matte and transparent. It is used in public buildings, lighting of shop windows, lighting of furniture and commercial equipment.

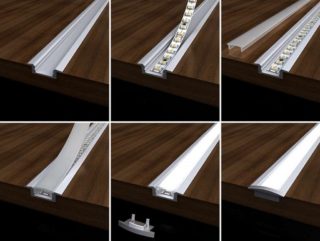

By device, profiles are distinguished:

- Corner. They are used when the standard profile is inappropriate. Examples of use - illumination of showcases, sales areas, cabinets, instead of a ceiling plinth. With the help of such a profile, you can independently come up with original schemes for the placement of LED filaments.

- Embedded. This model looks like a regular metal profile. It is quite bulky and has a number of advantages. These include resistance to aggressive environmental influences, reliability, fastening strength. It is recommended to mount the system using specialized glue or fastening. Then the design will be of high quality and reliable.

- Mortise. These types of profiles are installed to illuminate various furniture - for example, kitchen units, beds, wardrobes. Profile colors are usually gold and silver. Length - 1-2 meters. In order to diffuse light, an optional matt light filter can be installed. This allows for a more attractive appearance of the furniture.

The profile performs not only the role of a stacking box, but also the function of heat removal. Therefore, you cannot buy cheap plastic products that are not resistant to the heat of the tape.

Stretch ceiling connection diagram

First of all, the length of the thread is determined. The required size can be obtained by splicing several tapes according to special marks. The entire developed system is assembled on the floor, after which the quality of contacts and stability of operation are checked.

If a colored RGB tape is used, the connection to the controller is made in compliance with the marking. Compliance with the labeling is not necessary for single-color tape. The controller must be connected to the power supply, also observing the marking. It is impossible to confuse the wires here, otherwise the duralight will burn out. The last step is to connect the switch.

The assembled structure is connected to the network and checked. Then it can be fixed to the ceiling. Then the operability is checked again on the ceiling, after which the canvas is completely assembled.

Installation and connection recommendations

Before gluing the LED strip, prepare the surface for installation in advance. It must be degreased with alcohol, and then wiped with a dry, clean cloth.

Products with a power of more than 10 W / m are mounted in metal and aluminum profiles. Plastic is not able to provide optimal heat dissipation. An aluminum backing can also be used.

If the duralight is mounted on conductive surfaces, the tape should be insulated. To do this, it can be placed in a frame.

During assembly, the integrity of the conductive tracks must not be violated. Otherwise, the tape will not work.

It is recommended to connect large lengths in a parallel way. With a serial connection, overloading of the conductive paths will occur.