Very often, in production and in everyday life, it becomes necessary to work with energized lines. This is a forced decision that is made when there is no way to turn off the power supply. To carry out cable laying, repair and replacement of devices without turning off the current, special tools are used - dielectric screwdrivers.

Purpose and characteristics

Electric screwdrivers are designed for various manipulations directly on objects connected to the network, which are under voltage from 127 V to 1000 V. When the limit value is exceeded, devices of a different type are used with a higher degree of protection.

The tool is designed and created to ensure the safety of a person from electric shock when servicing such devices:

- sockets;

- packet switches;

- automatic modules;

- knife switches;

- relay;

- counters.

Using a dielectric screwdriver up to 1000 V, the master does not need to use additional equipment (gloves, rug). It is enough to have mounting goggles to protect the organs of vision.

Electric screwdrivers belong to the category of special tools that must meet the requirements of GOST 21010-75. A distinctive feature of the products is the inscription "1 kW", applied or embossed on the handle.

Dielectric screwdriver device

Electric screwdrivers have a standard device for this type of product. The differences lie in the materials from which the component parts of the tool are made.

It consists of the following parts:

- Lever. Designed to ensure a tight grip and hold of the screwdriver by the electrician during routine or emergency work. It is made of polymer materials that are resistant to external factors. There is a wide selection of models in different shapes and sizes.

- Kernel. It is a transitional link between the handle and the energized object. In order to prevent electric shock from slipping off the hand, the rod is covered with plastic insulation along its entire length.

- The sting. It is a tip for gripping products with splines of a certain configuration. Depending on the design, it is part of the shaft or the base for removable bits.

The design of the tool is such that it can be used for any non-electrical household work. The item is versatile and convenient in all respects.

Screwdriver size

Depending on the characteristics of the tasks being performed, tools with different parameters are used. The dimensions of the products are subdivided according to the length of the pin and the width of the spline part.

According to the first parameter, the classification is as follows:

- Short. The mini electric screwdriver is 5-8 cm long and is designed to work in confined spaces or small parts.

- Average. Products 9-20 cm are used for standard work on household and industrial equipment.

- Long. The size is from 21 cm. The tool is designed for unscrewing parts with large splines or in hard-to-reach places.

The tip size ranges from 2.5 mm to 10 mm. The choice is made based on the characteristics of the task.

Handle

The handle is made of a special polymer plastic - polycarbonate or polyethylene. The top is coated with polyformaldehyde, which is an excellent insulator.

The material has the following properties:

- hydrophobicity;

- strength;

- wear resistance;

- constancy of indicators;

- resistance to aggressive chemicals;

- impervious to cooling and heat.

With the addition of red pigment, the detail becomes prettier and takes on a presentable appearance.

In cross-section, the handles of various models have the following shapes:

- square;

- a circle;

- triangle;

- hexagon;

- gear.

The configuration does not affect the technical characteristics, but it does determine the usability.

Bar properties and shapes

The rod is made of durable tool steel grades 8HF or U7. On top of the iron, a galvanic layer is applied to protect it from corrosion. The core is firmly fixed in the handle, which is produced by pressing, melting or using matching plugs in collapsible models.

The cores can have the following cross-section:

- a circle;

- square;

- hexagon.

The form determines the convenience of carrying out certain works in various conditions. The presence of insulation on the shaft provides additional support for the fingers of the palm. The coating is made of polyformaldehyde, a thin layer of which protects against a current of 1 kW.

Sting shape

The working part of the device is characterized by increased strength and reliability. It is made of hardened powder coated alloy steel. The top layer is highly resistant to alkalis, acids and other active liquids. For the convenience of gripping, screwing in and taking out the hardware, the sting is magnetized. Thanks to this, the parts are tightly held on the rod in the desired position.

According to their structure and purpose, the stings are plug-in and slip-on.

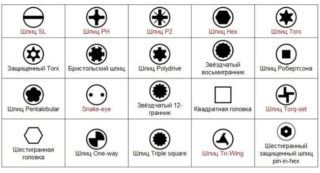

In turn, the internal ones have the form:

- flat;

- cruciform;

- hex;

- pin;

- star-shaped.

Couplings are used for nuts and bolts with a certain number of edges and corners. They are good in all respects analogs of wrenches.

Types of tools

Screwdrivers for working under current are the same in terms of their device as counterparts for turning and locksmith's work. The highest quality devices are outwardly different from household products in the appearance of the rod, covered with insulation.

By purpose, the tools are divided into the following types:

- Jewelry work. Small in size with fine stings. Used in conjunction with testers to determine the voltage level.

- Household purposes. Products are configured with conventional tools. They can be used both for working with electricity and for adjusting furniture fixtures.

- Professional. The tool is large, powerful, devoid of frills - only configuration and marking.

Products are purchased by individuals and organizations.

Screwdriver marking

There is a globally accepted marking system for devices for working under voltage:

- SL - flat;

- PH - cross;

- PZ - hex;

- HEX - plug;

- TORX - star-shaped;

Quality products are stamped with the VDE DIN EN 60900 standard.

Selection of dielectric screwdrivers

To select a reliable and safe electric screwdriver set, it is recommended that you consult the top brands rating.

Priority should be given to products that are certified by the following experts:

- DIN;

- TÜV;

- EN;

- UL;

- VDE.

These are the most reputable commissions and experts who have experience, equipment and testing grounds to establish the compliance of product characteristics with safety requirements.

When buying a product, you need to pay attention to the convenience of holding the tool in your hand, the absence of mechanical damage, uniformity of color, and the presence of a certificate.

It is advisable to purchase sets of dielectric tools for professionals and individuals planning large-scale construction. The kits are packed in plastic cases and may contain a set of one-piece and replaceable items. The choice depends on the priorities of the master and the variety of items presented. Products are gaining popularity, where there is one handle with a seat and many magnetic bits of various configurations.