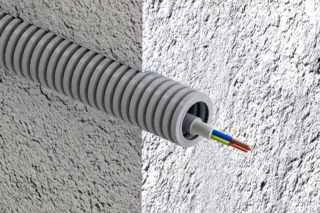

In accordance with the rules for the installation of electrical equipment, corrugated pipes are used when laying low-current networks or electrical wiring. This is due to the fact that the corrugation is a pronounced dielectric that protects the wiring from mechanical and thermal effects.

What is corrugation

Corrugation, despite its simple design, is considered one of the most useful and sought-after inventions of mankind. Visually, it is a tube with a ribbed surface, which at the same time gives it rigidity and flexibility. Corrugations are made of various materials, the most popular are metal, aluminum, and plastic pipes.

Corrugation can be of different diameters, indicators range from 10 mm to 2 m. This product has a wide range of applications.

Scope of application of corrugated pipes

Corrugated pipes are widely used in various industries, as well as for domestic purposes.

- computer networks (white);

- general wiring (gray);

- connection of electrical appliances, household appliances (brown);

- laying of telephone lines (green);

- external wiring (red);

- for connecting heating systems, underfloor heating (blue);

- gas supply systems (yellow).

For electrical cables, special electrical corrugations made of polyvinyl chloride are most often used.

How to put a wire into a hose

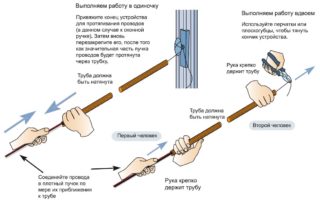

It is recommended to carry out the work together. This is due to the algorithm of actions.

- Remove the end of the wire (a kind of cable or string) from the hose and connect it to the cable to be installed. A hole is made in the wire winding, a thin wire is pushed through it and securely fixed by twisting.

- The hose is leveled along the entire length, only after that you can proceed to the cable plant in the corrugation.

- One worker firmly holds the end of the pipe from which the cable is wound, and the second pulls the wire from the back. This approach allows you to effectively push the wire.

- A fully stretched wire must be wrapped around the pipe to prevent the structures from moving relative to each other.

It is common for the wire to get stuck inside the corrugation. This is due to the weakening of its tension or the formation of bends. It is important to monitor the condition of the hose until the end of the pulling process.

How to pull the wire

You can run electrical cables along walls or ceilings using special clips. Their diameter is selected in accordance with the section of the corrugation. This method is more common because it fixes pipes securely and has an attractive appearance. In hidden places, it is preferable to use dowel screws or metal staples.

When laying pipes, the joints are connected using a budget connecting element - couplings. If the wires are not insulated in this section, it is allowed to seal the place of attachment to the pipe coupling with sealant. For the passage through the walls, special perforated sleeves are used, which, if necessary, are also treated with a sealant.

When pulling cables in a corrugation, it is important to avoid kinks that exceed the permissible radius.

Installation of electrical wiring in corrugated open way

Installation of corrugated pipes includes several stages. Algorithm for installing electrical wiring in the corrugation in an open way:

- To fix the hose, special clips made of high-quality plastic are used. They are characterized by different sizes, the choice will depend on the diameter of the pipes used.

- Clips are attached to surfaces with an interval of 30-40 cm. This is done using dowel screws or self-tapping screws. The choice of parts depends on the material from which the surface is made, for example, wood, concrete, brick, etc.

- For reliable fixation, the corrugation is pressed into the clip until a characteristic click appears. If the clips were selected correctly, the probability of spontaneous loss is excluded.

At the design stage, laying a schematic wiring path, you need to take into account the following important points:

- The maximum and permissible corrugation turning radius is 90 degrees. The smoother the angle, the better.

- The turns should not be located close to each other, the optimal distance between them is 4-5 meters. If this is not possible, for safety reasons, the wiring is additionally equipped with a junction box.

- The maximum length of an individual section is 25 meters, the permissible number of turns is 4.

How many wires can be laid in one corrugation

According to the rules for the installation of electrical installations, it is required to lay the main and backup cables through different channels, as well as the conductors of emergency and working lighting.

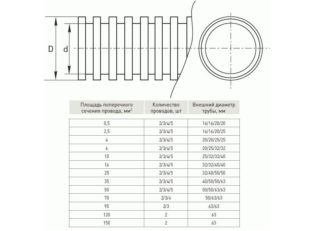

An approximate calculation of how many cables can be laid in one corrugation:

- With a diameter of 16, 3 cables are placed.

- If it is 20, 4-5 will fit.

- Diameter over 25 can accommodate 5-6 cables.

The exact amount is calculated assuming the pipe length is at least 35 meters.

If the integrity is damaged, metal structures are soldered with a special acid. If the integrity of the plastic corrugation is broken, the holes are sealed with polyethylene.

The advantages of corrugation are affordable cost, light weight, which greatly simplifies the process of transportation and installation, high resistance to thermal and mechanical stress, long service life.

As a rule, there are no difficulties when choosing and installing corrugated pipes. During the work, personal safety precautions must be observed; when working with electrical cables, it is important to de-energize the room and check the voltage in the conductors.

only the need to lay the cable in the corrugation is not spelled out. why is it needed ??? to rise in price?