In order to troubleshoot household appliances, electrical cables, you need to ring the wires with a multimeter. The use of a tester allows you to clarify the open circuit, the presence of a short circuit, the resistance of the power line. To ensure the safety of work, you need to understand the features of using the device.

- Need for continuity

- Continuity multimeter

- Markings on the front panel of the tester

- Measured value range

- How to connect a tester

- Features of Continuity and Resistance Test

- Instrument setup procedure before testing

- Compliance with safety precautions and rules for working with a multimeter

- Example of wire continuity

- Features of the dialing process

- The specificity of the continuity of some devices

- Fuse

- Diodes and LEDs

- Lamps

- What readings will the multimeter give after dialing

- Checking the integrity of the wiring in resistance detection mode

Need for continuity

The dialing process provides for the appearance of a buzzer if there is an electrical connection in the tested areas. The check is performed in the following cases:

- Switch or outlet not working. Initially, you need to inspect the connections in the junction box, check the lamp. Then the wire rings - the multimeter will give a signal about the problem.

- The network is overloaded. Using a heavy-duty hammer drill to drill a wall can rupture the telecommunication.

- Short circuit. Most often observed when the line is overloaded or as a result of outdated wiring.

- Search lived in large areas of the highway. The device is used in cases where it is impossible to identify the conductor by color marking.

- Breakdown of household appliances. The dialing is determined by the operability of switches, lamps, irons.

- Repair and soldering of boards. Testing the circuit with a multimeter is a mandatory stage of work.

The dialing mode is available for all devices with an LED marker.

Continuity multimeter

The tester allows you to determine the presence of voltage, resistance and current parameters. It consists of display, selection knob, ports, probes / probes, power supply. There are modifications depending on the type of meter:

- Digital. DTM devices with digital display for measurement display.

- Analog. AMM devices with current converters and a magnetoelectric ammeter measure the parameters of Hi-Fi equipment.

- Fluke. Equipped with two probes - positive (black) and negative (red), 9 V power supply, electronic display. Internal nodes are represented by a signal conditioning circuit and an analog-to-digital converter.

Some modifications measure the capacitance of capacitors, check transistors and diodes.

Markings on the front panel of the tester

The prefix "multi" in the name means the ability to check several parameters. Their symbols are applied to the body in the form of physical symbols or graphic drawings. The front panel contains:

- U - voltage designation;

- V - voltage in volts;

- I - current, the strength of which is regulated by placing the handle on the icon;

- A is the current strength in Amperes;

- Ω, R - resistance marking;

- Ohm - resistance parameters in Ohms;

- - | | - - marking of capacitors.

Graphic symbols are used for diodes and transistors.

In the socket of the device, marked with the inscription COM, there is a black probe. This is a common nest. The device can have 2-3 working holes for measuring voltage, low and high currents.

The hole marked U, Ω, Hz allows you to measure the parameters of voltage, resistance, frequency, and test radioelements. A probe is placed here, with which you can ring the cable or wires for an open.

The mA socket is designed to detect low (up to 1 A) and high (from 10 A) currents. Next to them there are symbols ~ or -, giving an idea of the constant or alternating nature of the current or voltage.

Measured value range

In addition to marking the values of the indicators on the front panel of the multimeter with manual adjustment, there are measurement limits. All values are in the form of multiples of the digit "2". In the selection process, it is required to put a value of the same order of magnitude with the measured value, but higher than it.

For example, to check the voltage of an outlet, you need to set the range to 2000 Volts. The wires are dialed in resistance mode with a minimum value of 2 ohms. For long conductors, 20 ohms are set.

Use the buzzer button while testing the circuit for a short.

How to connect a tester

To check the parameters of the power line and ring the conductors with a multimeter, it must be included in the circuit. The test area is located between the device pins, i.e. it connects to the terminal of the circuit. When measuring voltage, the apparatus is connected parallel to the test zone.

To measure the parameters of the current, the apparatus is thrown sequentially to open the circuit. A suitable location would be the point between the power supply outlet and the load terminal.

Features of Continuity and Resistance Test

I = U / RwhereI - current strength, U - voltage and R - resistance.

The tester works according to this principle. Having two parameters, it is easy to calculate the third one. The multimeter's power supply generates voltage and supplies current. Resistance measurements are shown on the display:

- zeros - the real value is less than the used one;

- digits with the first digit of zero - the indicator is less by 1 division;

- numbers greater than 1 - accurate measurements.

After comparing the initial data with the amount of loss of the measured object, you can calculate the final result.

Resistance marking on digital models is Ω.

Instrument setup procedure before testing

To check the wire for an open circuit with a multimeter, you will need:

- Set the switch to the dialing mode "-> Ι-" and activate the buzzer.

- Place the ends of the measuring probes with the test leads into the sockets. Red is located in the VΩmA hole, black - in COM. This is necessary to maintain the polarity of the measurements.

- Test the device itself for a malfunction by shorting the red and black probes to each other. A beep will be heard and the display will show 0 or a value close to it.

When checking the integrity of the wiring, polarity is not required.

Compliance with safety precautions and rules for working with a multimeter

It is necessary to ring the electrical wires and work with the multimeter, following the safety rules:

- Testing elements disconnected from the circuit to prevent them from affecting the circuit.

- De-energize the circuit by disconnecting the circuit breakers in the switchboard.

- Discharge capacitors by short-circuiting them to prevent data corruption.

- Take into account the distortion of the results from the mains diodes.

- Leakage current by touching the wires and probe tip with your hands will cause incorrect results.

- Use crocodile tips at the ends of the meters for secure contacts.

The distortion effect is noticeable when testing high resistance.

Example of wire continuity

A concrete example of working with a tester would be a standard power grid. The apartment is connected to it in accordance with the standards, consumers are grouped, each line is powered through an individual machine in the switchboard.

Situation: an outlet does not work in one room. It will be up to the user to find the cause of the failure. To solve it you will need:

- See if the switchboard automation has worked. If the elements are included, de-energize the specific line or apartment completely.

- Remove the socket from the socket, make a visual inspection for external defects and the quality of the contacts.

- For modern models, ring the terminal blocks.

- If the outlet has no breakdowns, test the quality of the conductor connection in the junction box next to the outlet.

- The main cable in the junction box must be broken, connected to the cores for the outlet and taken to the next consumer.

- There are 3 strands in the junction box - neutral, earth and phase. You need to touch the bare twist with the tip of the probe.

- With the second tip, the contacts of the socket are called in turn. You can fix one probe on the contact, and check the twist with the second.

There are no terminal blocks for standard sockets.

Features of the dialing process

The measurements have several nuances:

- If the twist is free from defects, it makes sense to test the live wiring. It is necessary to supply current by turning on the switchboard machines.

- If in doubt about the color coding, the phase is determined by touching the indicator screwdriver - the diode should light up.

- Working and protective neutralization are checked in the ACV mode above 220 V. The red probe is in phase, the black one is used to find zero and ground. Working zeroing N is reflected in the range of 220 A, protective PE - less than 220 V.

- It is taken into account that electricians do not always lead the wires into the distribution box. An outlet can be powered from an adjacent one or the elements of an adjacent room can be placed at single points of the walls.

- Due to the length of the probes of 30-50 m, it is allowed to connect the contacts of the socket with a jumper and a continuity in the distribution box.

Zeroing is checked only in a de-energized network.

The specificity of the continuity of some devices

You can use a multimeter not only for cable measurements. Experts use it to measure electrical equipment.

Fuse

Devices in the form of a small box with a thin inner cable prevent overheating and ignition of the circuit elements. Models without wiring are tested like this:

- The device is switched to the dialing mode.

- Probes are applied to both sides of the fuse.

- With a resistance of 0 Ohm and there is sound, the device works.

- The number 1 appears, there is no sound - the fuse has broken.

The breakage resistance index reaches a large value.

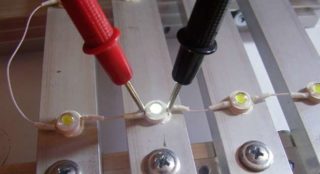

Diodes and LEDs

The polarity of the diodes is represented by a positively charged anode and a negatively charged cathode. For this reason, it only passes current in one direction. During testing, the multimeter is put into a special mode:

- Probes are placed on anodes and cathodes without reference to color.

- The tester is activated.

- The probes are swapped and the tester turns on again.

The serviceability of the diode backlight is determined based on the appearance of voltage in the first case and the number 1 in the second.

The polarity of the LED is opposite. It works with a plus at the anode and a minus at the cathode. The probes work in a similar way. If the voltage appears and then disappears, the LED is working.

Lamps

After switching the tester to dial mode:

- Place the first probe on the center contact of the light source.

- Bring the second probe to the side contact.

- The malfunction is determined by the buzzer and the 3-200 Ohm indicator.

Only lamps with a threaded base are ringed with a multimeter. To test LEDs and fluorescent lamps, you need to remove the CFL spiral and touch the probes to the terminals on the board.

What readings will the multimeter give after dialing

The integrity of the cable is checked only at the ends with the insulation removed. After touching the bare ends with the probes, the device will display:

- a sound signal and the presence on the display of 0 or a value close to zero - the wiring is intact;

- number 1 on the screen, no buzzer - the cable is damaged.

With an internal break, the numerical readings will be in the region of several megohms.

Checking the integrity of the wiring in resistance detection mode

You can check the electrical wiring with a device that does not have a ringing wire. To do this, you need to select the resistance change mode. The probes are thrown up by analogy with a dial tone and the resistance search mode is set (symbol Ω).

The measuring process starts at the minimum scale value - for example, 200 Ohm. The rest of the work is carried out in the same way as dialing in with tracking the readings of the device. In case of continuity of the conductor, the size of the resistance will be displayed on the screen. If there is a break, the data will not be displayed, the device will go into OL (reboot) mode.

Using a multimeter allows you to give an objective assessment of the quality of home wiring and the performance of some devices. The disadvantage of the tester is that it is used only in case of minor malfunctions, serious power line failures should be eliminated by specialists.