NYM power cables belong to the category of electrical connectors made of copper. Their main task is to implement internal wiring. They are laid in various building structures, including fire hazardous ones. Initially, they were made and used only in Europe. Today in Russia there are several factories specializing in the production of power cables according to their own specifications.

Description and transcript

NUM wire is a cable product that has become widespread for lighting and household purposes, as well as stationary power, where voltage indicators are not more than 0.66 kV at frequencies of approximately 50 Hz.

Installation of an electrical product is possible inside dry and humid rooms, in a humid environment and in an open space, but only with strict observance of the required level of protection against ultraviolet radiation and mechanical stress. For safe operation, corrugated pipes, metal hoses and cable channels are used. It is not forbidden to hide power cables under layers of plaster or lay on top of it, in concrete or brickwork.

It is forbidden to press a power wire of the NUM type into vibro-filling or stamped concrete.

Explanation of NYM marking designation:

- N - belonging to the Normenleitung classification of cable products, the quality corresponds to German standards.

- Y - insulating material was used in the production - polyvinyl chloride or PVC plastic.

- M - installation in different conditions is possible.

The insulating surface must additionally bear the VDE marking, which indicates that a particular product is manufactured in accordance with the German industry standards Veiband Deutscher Electrotechniker 0250 and can be used in areas with an increased risk of emergency situations.

Design features

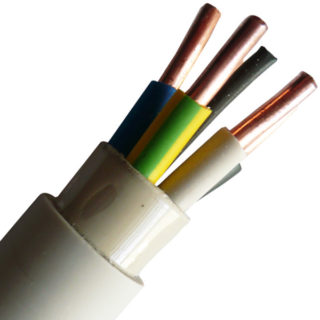

- High quality copper conductor. The number depends on the modification of the wire, it can be from 1 to 5 conductors. The cross-sectional area of the veins is also variable, the value varies in the range of 1.5-35 mm2

- Insulation of conductors is made of high-quality plastic alloy - polyvinyl chloride. The surface of the material can have a different color depending on the number of cores and the purpose.

- A sealing material that is made from unvulcanized chalk-filled rubber. Its main task is to prevent moisture penetration into internal cavities and to provide high-quality additional insulation. Thanks to this design feature, the NUM wire is not subject to combustion. It only melts and keeps its round shape.

- The outer shell, which is made of sheet-type plastic. Its function is to protect conductive conductors from corrosive substances and mechanical stress. Its limits determine the total cross-sectional area. This parameter indicates the ability to use an electrical product in trays, voids, and niches.

The layer between the insulating and sealing material is usually white in color for easy cutting and increasing the flexibility of the product.

Benefits of using

The main advantages of power cables:

- High degree of elasticity.The rubber layer between the sealing and insulating layers gives flexibility. This allows the product to be used rationally in hard-to-reach places and underground.

- The cable is made of non-combustible materials, therefore it is recommended to use it in fire-hazardous building structures.

- High quality. Each cable undergoes various tests before it reaches the store shelves.

The NUM wire has a large number of advantages, which are noted by experts in the field of electrical work. They are especially often used for the implementation of power and lighting purposes.

Varieties of NYM wire

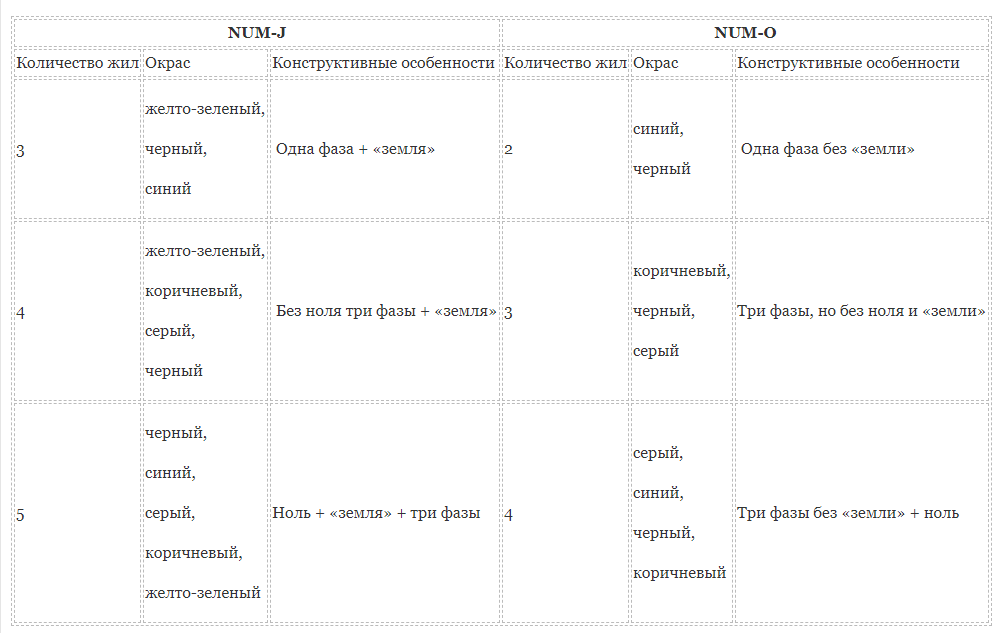

The wire grade is produced in several modifications - NUM-J and NUM-O. They have identical specifications.

Power cable specifications

- The magnitude of the rated voltage. It can be operated in electric lines with a supply voltage not exceeding 660 V and a frequency of 50 Hz.

- The bending radius should not be more than 4 external diameters of the electrical product itself.

- The rated operating current is determined by the cross-sectional area of the conductor; this parameter determines the maximum allowable current value that can flow for a short time in case of abnormal or emergency situations.

- The resistance of the insulating material determines the dielectric properties of the material used.

- Operating temperature is the temperature range at which the wire can perform its functions without destroying the elements and losing the specified network parameters. For NUM wire, the temperature ranges from -50 to +50 degrees Celsius.

- The core resistance is determined individually in each specific case during testing, determines the permissible amperage and throughput.

If difficulties arise when choosing a cable, it is better to consult with a specialist from the store.

Analogs of NUM wire

Main manufacturers

If the budget is limited when purchasing a power cable, you should pay attention to domestic developments, the quality of which is not inferior to international standards, and the cost is much lower. Among the main domestic manufacturers, one should highlight:

- Pskovkabel;

- Sevkabel;

- Kamkabel;

- Concorde.

If we consider foreign manufacturers, the following have all the required quality certificates and delivery to Russian markets:

- Turkish Denizli Cable LTD.

- Serbian Novkabel AD.

- French Nexans.

- German manufacturers: TKD Kabel, Kabeltec, Lapp Kabel.

The non-combustible power cable NUM is actively used in both industrial and household electrical work. It is indispensable for wiring in wooden structures, as well as outdoors. However, the material is afraid of ultraviolet radiation, so direct sunlight is contraindicated.

At home, NUM wires are used to switch lighting lines and connect sockets. It is also not forbidden to lay an electrical product in the ground, but first, experts recommend threading the product into a metal hose or corrugation.

To eliminate the likelihood of purchasing a low-quality product, it is better to buy it in large hardware stores or from official representatives. It is recommended to check the quality certificate, availability of accompanying documentation.