Junction box is a type of mounting device. There are a number of alternative names for the product: junction box, junction box, junction box or junction box with terminal blocks, junction box. This is a basic tool for organizing an electrical network in industrial and domestic conditions. The case accommodates the circuit of a limited section of the circuit, protects the branching node of the electrical wiring, simplifies access to it for repairs, upgrades, and prevents human contact with bare conductors. Built-in terminal blocks for junction boxes ensure ease of wiring and secure connections.

Switchbox selection algorithm

The location of the device is the first criterion for its selection. The markings indicate suitable operating conditions. Types of climatic performance are widespread: U1, U2, U3, where U - use in a temperate climate, 1 - street version, 2 - located under a canopy, 3 - indoors.

IP rating **. In dry rooms, IP20 is sufficient, conditions of high humidity and open spaces will require IP44, IP55, IP65.

Body material: aluminum, steel or fireproof plastic. Thick-walled steel boxes are placed at production facilities, in places with an increased risk of fires. In residential and office buildings, polymer models are more common. The exception is wooden houses, in which metal boxes are required to be installed.

Junction boxes with terminal blocks differ in the nature of the wall on which they will be fixed. The manufacturer indicates the relevant information in the product description: plasterboard, brick, hollow, concrete, wooden walls and their thickness.

The type and distribution of the electrical network determine the size of the product, the number of holes in it. External wiring involves overhead (external) devices, hidden - internal (secret). The number of cable contacts placed affects the dimensions of the electrical box and the terminal block itself, the number of holes. In this case, the margin for possible additions to the network must also be taken into account. Terminal blocks have 2-5 poles, which makes it possible to use them in single-phase, three-phase networks of types TN-C, TN-S, TN-C-S.

Personal preference is another condition for choosing the right model among the variety on the market. Manufacturers produce round and rectangular (square) products, use different colors. The lids of the box open, move aside, remove completely, some are sealed.

Installing and replacing the junction box

- Overhead models do not require a specially equipped socket, unlike hidden ones. If the base is solid (concrete, brick), a recess is drilled in the wall with a special crown, the soldering box in it is fixed with mortar and self-tapping screws. Hollow and plasterboard partitions allow the device to be secured with fixing clamps.

- After fixing the case, cables are brought into the junction box. They enter through special holes sealed with membranes or oil seals.

- The next stage is stripping the veins from general and individual insulation. In the arsenal of electricians there is a tool adapted for this work, but you can get by with a simple knife. The minimum length of the “bare” edge should be 4–5 cm and should be designed for reconnection without excessive tension.

- When working with stranded conductors, lugs are used, which facilitate the fastening of the wire and exclude the possibility of damage to the thin strands of the conductor.

- The power supply is renewed after checking the correctness of the assembly.

The placement of power grid nodes is subject to the PUE. This should be taken into account when planning a new wiring or upgrading an existing one. The main thing is accessibility, the cover should not be hidden deeper than a sheet of wallpaper or a thin layer of putty. Distribution is placed in line with sockets or switches 20-30 cm below the ceiling.

In old houses, the location of the installation boxes is determined by the type of building:

- "Stalinka" - the boxes are located in the cavities, so the walls are tapped;

- "Khrushchev" - iron covers protrude 20 mm;

- "Brezhnevka" - the places between the wall and the ceiling are passed through a metal detector to calculate the galvanization;

- panel high-rise building - the lines from the sockets are examined with a screwdriver indicator, in the right place the brightness of the light will increase;

- in the case of drywall, you will need a hidden wiring detector.

Even a high-quality and expensive device will not be insured against errors during the installation process. Among the most common are:

- ill-conceived branching, connection diagrams;

- the choice of contact devices does not correspond to the cable cross-section, mains voltage;

- the box was chosen without a reserve of space, which is inconvenient and unsafe;

- oxide films have not been removed from the surface of the conductors;

- the selected sleeves do not match the stranded conductors;

- not deep enough the end of the wire is immersed in the cavity of the terminal block;

- the tension creates a mechanical breaking load on the joints.

High-quality execution of all stages of the disconnection will ensure the full functioning of the network.

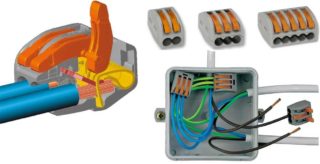

Types and advantages of connection terminals

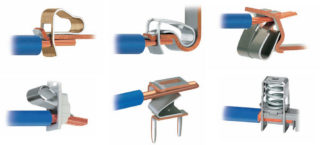

Among the traditional methods of switching wires, the terminals are distinguished by their ease of installation and the possibility of easy disassembly, but with a lower safe load. By the type of connection there are:

- screw;

- spring;

- knife.

The wires that are fixed with screws cannot be of different metals. For stranded conductors, use brass ferrules. The diameter of the clamping screws depends on the cross-section and the number of cores that are connected. The connections should be checked and tightened annually.

Self-clamping terminals are used for both permanent and reusable connections. The difference lies in the stiffness of the spring.

The advantages of contacts in such blocks are the ability to combine wires of different cross-sections, compensation of conductor deformation by spring pressure, vibration resistance, core integrity with multiple connections, ease and speed of installation.

Knife contacts are needed where a continuous conductor (neutral) is required. Such devices save time on stripping insulation, as they cut through it independently.

If it was not possible to select the required electrical terminal box, you can select the strips and place them in a universal hollow product.