Wiring in places with limited space is done with soft conductors made of many copper wires. Such devices include PGV wires. They can be used in internal wiring as a wiring or power conductor. The electrical wire has its own technical characteristics and features that you need to familiarize yourself with before purchasing and performing electrical work.

Decoding and construction

Wire marking PUGV is traditional, it contains the purpose and characteristics. You can decipher it using standard notation.

- P - wire. Indicates the type of conductor.

- Y - installation. Shows the purpose of the conductor.

- G - flexible. Lived multiwire. In the PuV models, a single-wire core is used.

- B - insulation made of PVC material.

Wire version - only single-core. In the marking, you can also see the designations ng and ls - in this way, the absence of combustion propagation and the release of a small volume of smoke are indicated.

There are 7 or more copper conductors in the wire of the PGU, which are twisted together. The number of copper wires can be increased to increase the cross-section and achieve the optimum level of flexibility.

Conductor insulation is made of the most common material in cable production - polyvinyl chloride or PVC for short. The insulation is laid in one layer. Above, marking is applied at a distance of no more than 500 mm from the nearest designations. The conductor is being developed in accordance with the accepted GOST 31947-2012.

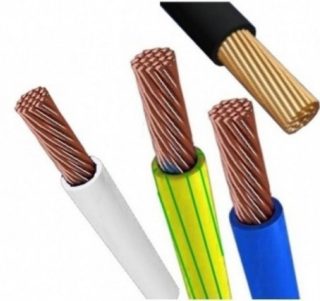

The insulation can be painted in a wide variety of colors. There are products even of the same color as the marking of grounding wires - yellow-green.

Specifications

Installation wire PUGV has the following characteristics:

- Voltage 450/750 V for alternating current.

- Voltage up to direct current - up to 1000 V.

- Frequency up to 400 Hz.

- Working temperatures from -50 ° to + 75 ° С.

- Humidity up to 98%.

- The maximum insulation temperature is up to 160 ° C.

- The bending radius must be at least five outer diameters.

- Section from 0.5 sq. Mm to 400 sq. Mm.

- The operating time is 15 years. Depends on the operating conditions of the cable. Under the aggressive influence of the environment (ultraviolet light, rain, snow), it can be reduced up to two years.

- It can be used in the UHL climatic zone.

- 5 class of flexibility.

- The conductor is flame retardant (in case of single laying).

You can buy a cable in coils with a length of 100 m. The actual length depends on the manufacturer, supplier or store.

Scope of application

The characteristics of the product allow the use of the power wire PUGV in the installation of electrical panels, lighting group, connection of power conductors. It is actively used in the assembly of panels and installation of circuits in hard-to-reach places.

PGV is often used for assembling circuits inside lighting devices due to its flexibility. In this case, it is important to observe the temperature conditions - the heating should not be strong, as well as the temperature in the room itself. If the room temperature is elevated, other heat-resistant cables are used (for example, RKGM).

The flexibility of the cable also allows the use of PUGV in non-stationary installation of electrical equipment. But it is better in such cases to use double-insulated stranded wires - for example, PVA, ShVVP.The presence of double insulation reduces the likelihood of short circuits.

PGV wires are laid in corrugations or cable ducts in the case of open wiring. This allows you to protect the product from mechanical damage and the influence of ultraviolet radiation.

Analogues, manufacturers and selection of a suitable cable

The installation wire PUGV is a complete analogue of the classic PV electrical installation product. It can completely replace devices such as PV-3 and PV-4.

Almost all Russian manufacturers offer high quality wires. But at the same time, one can single out the leading domestic manufacturers of electrical installation products, which include:

- Power cable;

- Kavkazkabel;

- Kamkabel.

When choosing a wire from any manufacturer, you should use the following recommendations:

- Visual inspection of the wire. You need to make sure the integrity of the structure and the compliance of the declared section with reality.

- Determination of the resistance of the veins. Can be done with an ohmmeter.

- Electrical insulation tests. For this, its resistance is measured and high-voltage tests are carried out.

- Checking the marking for correctness. Using a conductor without proper marking can be dangerous.

The product must have a special label indicating the manufacturer, cable brand, production date, weight and length, as well as mandatory conformity marks.

Difference from PV-3

The wires PV-3, PV-4 and PUGV are analogues. To understand if there are differences in them, you need to understand their parameters.

PV-3 is a power element used at the declared operating voltage and constant current. Used in cases where increased product flexibility is important. Has insulation that is not subject to combustion and mold. Withstands temperatures up to 150 ° C.

The conductor ПУГВ has minimal differences that allow them to replace PV-3 and PV-4. The main difference is the number of veins. The PUGV has 5 cores, which make the cable more flexible. There are also minimal changes in the insulation temperature limit and the ambient humidity. All changes that have occurred with the cable are associated with a change in GOST, therefore PV-3 and PA-4 are complete analogues.