LED lamps are very popular with individuals and organizations of all forms of ownership. The products are distinguished by good brightness, an eye-pleasing range of luminescence, and resistance to dampness and drops. Mass production has led to lower prices and product quality. Burnout of diodes happens much more often than we would like. At the same time, the cost of the product is tangible enough to cause annoyance if the product breaks down. There is a way out of the situation, since LED bulbs can be repaired with your own hands, with minimal knowledge and skills in this area.

LED lamp device

The LED lamp is a prefabricated device consisting of electronic and mechanical parts, assemblies and mechanisms. The principle of operation is designed to change the parameters of materials under the influence of an electric current.

The LED lamp consists of the following fragments:

- Base - for connection to a 220V household network. Cylinders of sizes E 14 and E 27 are used.

- Housing. Made of heat-resistant plastic. Serves for placing an electrical circuit.

- Dielectric layer between base and case.

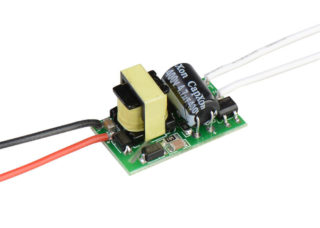

- Driver. An electronic unit designed to stabilize the input signal to the operating parameters at which the crystals can function.

- Crystals. Emit a glow when an electric current passes through them.

- Radiator. Designed to receive and remove excess heat from the heating parts located on the board.

- Cap. Serves for uniform dispersion of the light flux emitted by diodes.

The termination of the glow indicates a breakdown of one of the circuit elements. To fix an LED light bulb, you need to unscrew it from the socket, open it, carry out diagnostics and replace the faulty element.

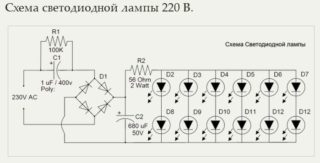

Driver circuits and how they work

The device performs the following tasks:

- rectification of electricity;

- lowering it to a given value;

- voltage stabilization;

- protection against electromagnetic radiation;

- smoothing impulses.

Drivers are categorized according to their design:

- With current stabilization. The device works on the principle of pulse-width modulation, creating an even and uniform signal, ensuring high-quality and long-term crystal life. The products are distinguished by high efficiency, the ability to convert current of any voltage, and a wide temperature range of operation. The device is based on a microcircuit that connects directly to the network. It has found application in lamps used for street lighting and fire alarm systems.

- With voltage stabilization. The basis of the block is an electronic chip, which is responsible for the precise boundaries of the output signal.This eliminates the risk of lamp burnout due to peak loads and achieves an even glow. The downside is the high cost of the product.

- No stabilization. The node is mounted on a board and has a rather simple device, which affects the final price of the product. The converter, resistor and capacitors protect the crystals from mains noise, short circuit, smooth out ripple and rectify the current. The advantage is the ease of repairing LED lamps and the variability of the output signal. The disadvantage is that the device converts the input signal without stabilizing it, which leads to the burning of diodes. Such models are used in the production of low power lamps used to illuminate surfaces and objects.

When buying, you need to check with the seller about the possibility of disassembling the LED light bulb for its repair or modernization.

Reasons for lamp failure

Emitted dim light or no light at all is evidence of product failure. Manufacturers guarantee up to 8 years of lamp operation, subject to the operating conditions that are prescribed in the instructions. Some products can withstand this period of time, but about half of each batch breaks within the first year.

The reasons for this phenomenon:

- Critically high values of the incoming voltage. Even high-quality protection, if it does not burn out, will give out a distorted signal, since it is designed for a certain current range. With frequent power surges, equipment wear is much faster.

- Wrongly chosen ceiling chandelier. Despite the fact that LEDs for a 220 V lamp emit little heat, in small closed shades they overheat and quickly fail. The same can be said for condensers that dry out from high temperatures.

- Use in the manufacture of low-quality components. In order to reduce the competitiveness of their products, most manufacturers use low quality parts with a limited resource.

- Violation of the rules of transportation and storage. The technical properties of the products change from impacts. A cracked bulb can cause moisture to enter the housing and cause a short circuit. From severe overheating and cooling, the operating parameters of capacitors and microcircuits are violated. Long exposure to the sun leads to cracks in the plastic.

- Non-compliance with design rules. If the wiring is made with thin wires, they will warm up on the contacts. Excess heat will be transferred to parts, which can burn out within a few days.

To prolong the life of the LEDs, change the wiring, check the parameters of the input current and take measures to stabilize it. The best solution is to install a dimmer. This device adjusts the power supply to the lamp, preventing it from swinging to dangerous levels. In addition, it is not recommended to buy cheap products that break down quickly even under ideal conditions.

An example of repairing an LED light bulb

Most products use 6-8 crystals installed in series or in parallel. You can find out which LEDs are used in 220 V lamps in specialized stores. The cost of one crystal is several times less, so it makes sense to spend time and restore the performance of the whole product. Another option for purchasing consumables is to use another previously burned out lamp. Only 1 diode has failed in it, and the rest can be used to restore the performance of other devices.

To repair the LED lamp, you will need the following tools and materials:

- soldering iron with a thin tip;

- tin or solder;

- rosin;

- soldering acid;

- tweezers;

- surgical clamp;

- holder for fixing the board;

- portable gas burner or turbo lighter.

A damaged light bulb should be repaired with protective goggles and gloves. In order not to spoil the countertop, it is recommended to put a piece of plywood on it.

To gain access to the insides of the device, you need to disconnect the diffuser cap from the body. Its fastening in different models is carried out on a thread, glue or silicone. If in the first case, disassembly is simple - just turn the cap counterclockwise and remove it from the thread, then you will have to work hard with the glue. To open the device, you need to pour a small amount of acetone into the gap between the flask and the body. If the composition does not immediately dissolve, attempts are repeated until the desired result is achieved. Heat can be used to melt the silicone at the joint. For this, a regular household hair dryer is used. Care must be taken so that the plastic does not melt.

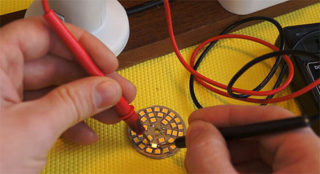

Do-it-yourself 220 V LED lamp repair begins with troubleshooting. First, a visual inspection of the boards is carried out, on which crystals and driver parts are attached. Damage may be indicated by blackening at the point of contact. If these signs are absent, you should use a tester and ring all connections. A missing circuit will indicate a faulty item. After that, you can start fixing the problem.

Driver repair

If the converter breaks down, it must first be removed from the housing and fixed in the holder. The wires are disconnected with a soldering iron, they must first be marked or photographed so as not to be confused during assembly. After that, the operability of all the parts that are placed on the board is checked.

If the microcircuit is burnt out, it is completely separated. The product is grasped with tweezers, the soldering point on the back of the board is heated. When the tin is melted, the terminals of the chip will easily come out of the holes. Replacement is done in reverse order. If there is not enough solder, it is added with a soldering iron. This must be done carefully so as not to snag adjacent jumpers. To prevent this, the surface of the board near the solder is covered with a heat-resistant varnish.

When the driver consists of a chain of resistors, capacitors and rectifiers, the board must be visually inspected first. Blackening or swelling of the parts indicates a malfunction. If there are no such signs, you will have to solder and check each element. This must be done in turn, so as not to break the chain by mistake. It is better to insert the serviceable element back and solder immediately after the diagnosis.

The defective part is replaced with an analogue. You can save time and money by using a working resistor or capacitor from the donor lamp in which the crystal flew.

Another solution to the problem is the purchase of several drivers, the characteristics of which correspond to the diode bridge. To replace them, you need to re-solder 4 connecting wires, and then put the cap back in place.

Replacing LEDs

If the cause of the lamp failure is a burned out diode, it is replaced with a serviceable part. This procedure should be performed in the following sequence:

- Turn on the soldering iron, after placing it on a non-combustible stand.

- Mark where the positive and negative wires are located. Detach the strip with crystals from the case. This is done with a soldering iron by melting the contacts.

- Clamp the board in the holder. Grasp the faulty crystal with tweezers or a surgical clamp.

- Bring the soldering iron to the contacts on the back of the part. Pull the diode away from the base at the same time.

- Separate the burnt part. Solder the working crystal from the donor board in the same way.

- Remove the scale from the place on the radiator where the burned-out diode was located.

- Prepare a serviceable part for installation.To do this, its contacts are adjusted in width to the holes on the board, after which they are processed with rosin and tin.

- Insert the new element with the contacts into the holes. Care must be taken to observe the polarity.

- Bring a soldering iron with a drop of solder to each wire and fix them to the base.

- Treat the soldering area with a varnish to protect it from corrosion.

- Restore the layer of heat transfer paste. Install the board on the heatsink.

- Solder the wires to the pins.

- Check the operation of the product by attaching it to a carrier or a table lamp with a switch. If problems arise, rework by replacing diodes or driver parts.

- Glue the cap to the base. It is better to use silicone glue for this. The repaired product can be used in a couple of hours.

In the absence of a soldering station and a hair dryer, you can use a turbo lighter. To perform delicate work, its flame is set to a minimum to limit the thermal effect to one contact.

Safety precautions when repairing 220 V LED bulbs

When repairing the LED lamp, the following safety measures must be observed:

- measurements and soldering should be carried out on de-energized boards;

- do not leave the included soldering iron unattended;

- carry out work in protective goggles, as there is a possibility of an explosion of the condenser;

- remove the cap with assembly gloves so as not to cut yourself with sharp edges or fragments.

Work should be carried out in a ventilated area, rosin vapors are harmful to health.