If you have the initial skills and the necessary tools, self-repair of the light switch at home is quite acceptable. For its successful implementation, you will need to understand the types of known switching devices, as well as the principle of operation. All this knowledge will help to quickly and without any problems restore the operability of a failed switching node.

Types of switches and principle of operation

According to the number of switched chains and the number of keys, all existing varieties of these devices are divided into the following types:

- one-key models;

- two-key samples;

- three-key devices.

Until now, another kind of old devices are used, in which the element that controls the switch mechanism is more like a button.

In addition, there are rare types of rotary switching products on the domestic market. In terms of the control method, they are a bit like a packet switch. There are also inexpensive Chinese devices related to touch sensitive devices. They do not require significant effort to operate - just bring your finger to the contact plate.

The principle of operation of a conventional circuit breaker is based on the closure of a movable and fixed contact when the key is moved to the upper position and their opening in the opposite action. The so-called "pass-through" switch works in the same way, which differs from the usual one in the presence of additional groups of contacts, as well as in the way it is connected to the lighting network.

Malfunction symptoms and main types of breakdowns

Before fixing a faulty switch, you first need to understand how it works, as well as familiarize yourself with the main reasons why it could break. Typical signs of breakage:

- when the button is pressed, the rocker mechanism starts to jam and does not move to the desired position;

- at the moment of switching, crackling is audible, and sometimes it is noticeable as something sparks inside;

- after pressing the button, the device simply does not turn on the lighting.

Usually, these malfunctions are observed with only one of the keys, but the possibility of failure of two or even 3 switching mechanisms at once is not excluded.

In the first case, presumably, the axis could fall out, on which the base of the key is fixed, or a foreign thing got inside (dust has accumulated). With the characteristic crackling and sparking, one of the closed contacts, or both at once, probably burned out. If the light does not turn on at all after pressing the key, the point is most likely that the contact at one of the points of connection of the conductors with the terminals is broken and the current does not go to the load. In this case, it is first checked whether the voltage has disappeared in the entire apartment and that the lamp of the illuminator is fully functional.

Troubleshooting Procedure and Safety Measures

Before proceeding with the repair of light switches in an apartment, it is advisable to thoroughly prepare for this procedure. First of all, you need to stock up on a working tool with which to repair products of this class. The set includes the following items:

- indicator screwdriver;

- tester (multimeter);

- regular screwdriver;

- side cutters or platypuses.

Disassembling and cleaning contacts

Before you fix the light switch, you will definitely have to disassemble it to the point in which the malfunction is clearly distinguishable. It is recommended to start repairing a broken device in the following order:

- Completely remove the voltage from the linear branch of the supply line or from the entire apartment at once.

- To disassemble the switch, for which first it is enough to remove all keys.

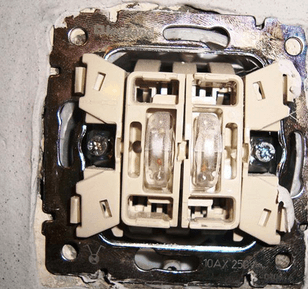

- After they are removed, the switching mechanism with a rocker rocker is "exposed", according to the state of which the nature of the breakdown is judged.

If, even before the complete disassembly of the device, weakened contacts were found at the points of inlet and outlet of the phase conductors, they should be tightened with force, having installed the locknuts first.

If at this stage of dismantling it is not possible to find traces of a malfunction or the damage is too serious, it is best to completely dismantle the device from the installation site.

Before you repair the faulty switch, you will have to unscrew the mounting screws and pull the box out with it, as far as the length of the conductors allows. If they are short, the fastening is loosened, and the device itself is taken out of the plastic case (first, it is remembered which of the conductors was connected to where).

After removing the device from the installation site and removing it from the box, it will be more convenient to inspect it for damage. During inspection, it is possible to detect several types of malfunctions:

- the axis of attachment of the rocker arm fell out, which returns to its place and is slightly flattened at the edges with side cutters; after that, the key will be pressed normally, without jamming;

- the contacts of the cross-over element are slightly burnt from frequent switching, which is corrected with the help of a zero skin;

- in case of severely burnt out contacts, the moving part of the mechanism will have to be replaced with a new part (from a spare working switch);

- if there is nothing to replace this part, you will have to buy and install a new device.

After eliminating all the detected faults, they begin to assemble the repaired device.

Switch assembly

To assemble the switch and install it in its original place, first its body is fixed in the junction box. After that, the dismantled conductors are carefully connected to the contacts, and the screws fixing them are tightened with force. Then the plastic cup is put back into the niche and fixed there with spacer screws. Next, it remains to replace the decorative panel and install the toggle key back.

Repair of 3 key switches or their two-key analogs is no different from the process already described for a single-key. In this case, everything will be repeated, only, possibly, to a greater extent. After installation in place, the device is checked for functionality.

Restoration of rotary and touch models

In rotary-type devices, characteristic malfunctions have approximately the same causes and manifestations as in keyboards. In their working mechanism, the closing and opening contacts also burn out and completely wear out, which is explained by their intensive operation. In addition, by analogy with the samples already considered, it is also possible in them to weaken the contacts at the points where the phase conductors are connected.

Restoration of switches of this class is similar to the approach already discussed for keyboards. Difficulties arise when the cam mechanism breaks down, which is unlikely to be repaired manually. In this case, experts advise to completely replace the device with a new product.

Touch switches at home cannot be repaired. Due to the complexity of the design of the dimmer device, their restoration is possible only in specialized workshops.