In the home and office sphere, wires of the SHVVP brand are often used. These inexpensive devices have good quality and a number of characteristics that make them used as cords and extension cords for most household appliances with low power. Ball screw cords are designed for a small amount of load, so they can only be used in domestic conditions and in offices. To create the entire wiring system, they are not suitable; they can only be used to connect individual sections of the lighting group or other devices.

Varieties of ballscrew wire and its device

You can find a ball screw conductor on sale in two versions - with copper conductors and bimetallic ones. The latter consists of aluminum, which is covered with a copper layer. It is used extremely rarely due to its reduced properties. Costs less than an all-copper cord.

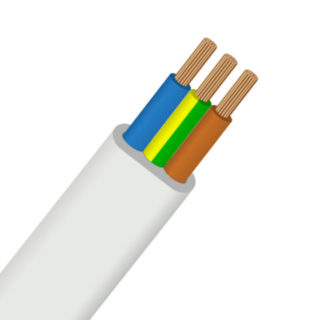

Regardless of the type of conductor, the ball screw consists of the following parts:

- Shell. It is made of polyvinyl chloride.

- Insulating layer. Made of PVC.

- Copper multiwire lived.

Manufactured with two or three cores. The fifth class of flexibility.

Each core is colored for ease of installation. If the shell is blue, it can be judged that this core is a neutral wire. The yellow-green color is used for the ground. The phase wire is brown or red.

Phase colors may vary. You need to check everything according to the documentation or use a special tester to determine the purpose of the core. The wire itself is usually white. Some manufacturers produce the product in black. The cost does not depend on the color of the cord.

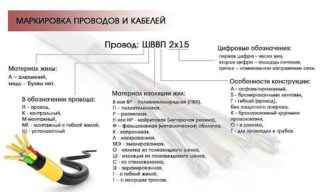

Decoding of marking

- Since the letter A is absent in the name, the material of the veins is copper.

- Ш - cord. This is a type of conductor with increased flexibility compared to conventional conductors.

- B - PVC core insulation.

- B - PVC insulation of the cord sheath.

- P - flat.

The main symbols can also be followed by the descriptions "H", "Ng" and others. They indicate additional parameters of the cord. The most common letter additions include:

- L - tinned copper. Allows you to simplify the soldering process. Reduces the risk of corrosion and other negative phenomena. Fastening - only using special terminals, non-removable fittings are prohibited for use.

- T - high temperature resistance of the cord. Can be used in high temperature and humidity environments. Cannot be installed in direct sunlight due to the negative destructive effect on PVC insulation.

- Ng is non-flammable. Has a low emission of smoke and gas during combustion. It can also be denoted by the Latin letters LS.

After the letter abbreviation, the number indicates the cross-sectional area and the number of cores in the cord. In addition, the year of manufacture is indicated. The final marking looks like a ШВВП 2 × 0.5 2009 (a cord with two conductors with a cross section of 0.5 sq. Mm. 2009).

Technical, mechanical and electrical characteristics

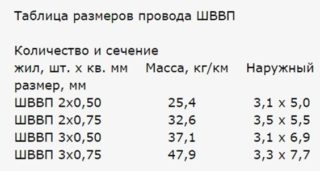

- Cross-sectional area. Cords are made for 0.5 sq. Mm. and 0.75 sq. mm. For this reason, such a conductor can only be used with a light load. On sale you can find products with a cross section of 1-6 sq. Mm.These values do not meet national standards, so the given wire characteristics do not apply to them.

- Number of lived. It can be 2 or 3. The cores must contain at least 7 copper wires.

- Working voltage 220/380 V.

- Insulation thickness. Minimum 0.5 mm, for the outer insulating layer the minimum value is 0.6 mm. Sheath color is usually black or white.

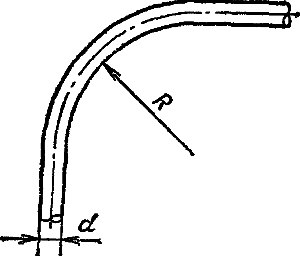

The bending radius of the ballscrew wire is 5 outer diameters - Bending radius - 5 outer diameters.

- Resistant to multiple bends. Withstands several tens of thousands of flexions.

- The service life is 2 years. If not subjected to frequent bending, the operating time can be 10 years.

- Working temperatures from -25 ° С to + 40 ° С.

- Frequency 50 Hz.

- It can withstand a peak voltage of 2000W for up to 15 minutes.

- The specific resistance of 1 meter of the cable reaches 270 ohms.

- The throughput of a three-core wire is 0.75 sq. Mm. is 1300 W.

- Current load for a product with a cross section of 0.75 sq. Mm. - 6A, for 0.5 sq. Mm. - 3A.

- The resistance is not less than 0.012 Mohm for a conductor with a cross section of 0.5 mm2. and with a temperature of up to + 70 ° C. The length of the cord during measurements was 1000 m.

The insulation resistance is tested between the conductor and earth and between two adjacent conductors. The check is carried out on a cord of at least 5 meters in length. The conductor is placed in water, after which 2 kV voltage is applied to it. As a result, leakage currents are measured. To check the insulation resistance between two conductors, a length of 2 m or more is needed. The sheath must be cut between the conductors. Further, the wire is also lowered into the water, voltage is applied to it and the leakage current is measured.

Areas of use

The small cross-sectional area does not allow the use of ball screws to work with powerful installations. Due to the possibility of passing electric currents of small magnitude, wires of different cross-sections have found their application in the following areas:

- Installation of the lighting group indoors and outdoors. For such purposes, a conductor with a cross section of 0.75 sq. Mm is used. Withstands loads up to 750 watts.

- Connecting LED strips to a power source.

- Connecting the bell buttons to the power supply.

- Products with three wires can be used to connect grounded sockets with increased electrical safety.

- Creation of extension cords. When connecting devices to it, it is important to monitor the total power. It should not exceed the value for which the ballscrew wire is designed.

- Connecting low-power desktop electrical equipment (computers, telephones).

- Connecting household appliances up to 1300 W (depending on the type of cord selected).

It is not used in the industrial field due to its characteristics. Suitable only for household and office use.

The analogue of the product is the PUNP wire. It is prohibited for use, since it has insufficient characteristics for organizing the supply of electricity to household appliances and the lighting group. Also, among the analogs, PVA wire with similar properties can be distinguished.

ShVVP cord supplies

For the device to work without interruption, you need to be able to choose the right cable products. Be sure to pay attention to the correctness of the labeling. It is applied in accordance with GOST 7399-97 and must be marked on the cord.

The wire must be marked with the manufacturer's trademark, standard size and date of issue. Marking in accordance with GOST requirements is applied every 500-550 mm. This rule can only be violated if agreed with the buyer in the production of products for reinforcement.

If the conductor is sold in coils, they must be labeled accordingly. It contains information about the product - designation, length, weight, name of the manufacturing plant, year of manufacture. Also, if the buyer requests, a technical control stamp can be applied.

The main manufacturers are Sevkabel and Elektrokabel. They produce high-quality and reliable products that meet all the declared characteristics.

Application features

The quality and duration of work depends on compliance with the peculiarities of using the cord. The high flexibility of the conductor makes it specific for connecting extension cords and electrical appliances. But do not connect devices with a total load of more than 2 kW to extension cords that work with this cord. Otherwise, the conductor will heat up above safe values, which increases the risk of a short circuit or fire.

Over time, frequent bending, especially at the joints, can lead to loss of insulation. Breaking the outer sheath is a signal to replace the wire section with a good one.

The rules require that during installation, all conductors are soldered and crimped with special ferrules. Only after completing this procedure can the conductor be connected to switching devices and meters. The need for crimping is associated with the multi-wire structure of the ball screw cord.

When connecting the cord to the plug, the wiring must also be done correctly. It must be installed in such a way that the force is applied to the external insulation, and not to the conductive wires.