In the process of installing electrical circuits in switchgears and power blocks, a busbar, or electrical bus is used. This is the name of a structure - a conductor made of metal with low resistivity.

Benefits of using busbars

The use of a bus in electrics instead of cable products provides significant savings in material, energy and labor resources:

- Installation takes 2 times less time than cable laying.

- Service life - up to 30 years without the need for complex maintenance.

- Flexible configuration allows you to perform high-quality and safe installation of the network, depending on the path of its laying.

- Busbar trunking has a more aesthetic appearance than group wire routing.

- The shielding of the conductor eliminates the influence of the electromagnetic field on the office equipment located nearby.

- The construction is fireproof and meets the safety requirements for the IP55 protection level.

The field of application of electric buses is the connection of electrical circuits in low-voltage networks or high-voltage discharge devices, substations, etc.

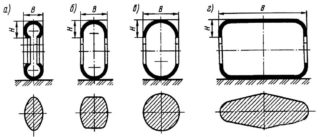

Classification of tires by section shape

Depending on the cross-sectional shape of the busbar trunking, there are:

- tubular structures;

- rectangular models;

- box conductors;

- two- or three-way models.

The advantages of rectangular conductors are efficient heat dissipation and low current resistance, which reduces active energy and limits reactive energy. Thus, it is possible to provide significant savings in expensive energy resources, which is important for large commercial and industrial facilities.

The area of application of the rectangular busbar trunking is the installation of networks and switchgears with a current strength in the range of 2000-4000A. It is possible to connect several flat buses to obtain two- or three-way configurations.

Flat and box-shaped busbar trunking modifications are used in networks operating under voltage up to 35kV.

The optimal modification is considered to be a tubular electric bus. Among its main advantages are efficient heat dissipation, high strength and uniform distribution of the resulting electric field.

Metals used in the manufacture of tires

Depending on the purpose and the required operating parameters for the manufacture of conductors, the following can be used:

- copper;

- aluminum;

- steel;

- steel-aluminum - a steel core covered with a twist of aluminum wires.

Among the advantages of aluminum tires are corrosion resistance, excellent electrical conductive properties, low weight and reasonable cost. For their manufacture, low-alloyed aluminum alloys with an insignificant content of silicon and magnesium are used to improve the ductility and strength of the metal.

Copper busbars with copper content up to 99% are in no way inferior to aluminum ones, but they are less widespread due to their relatively high cost.

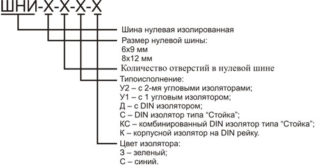

Busbar marking

The application of color marking on electrical tires is regulated by the current standards. Compliance with their requirements is mandatory for every manufacturer.The marking can be carried out both at the stage of production and after its completion. In the first case, colored insulation is used, in the second, a colored insulating tape indicating different phases of the conductor.

The color coding of tires allows you to accurately determine their type and purpose:

- The earth conductor is marked with alternating longitudinal stripes in yellow and green.

- The neutral and working conductor is marked with blue.

- Connecting conductors involves the use of all three shades in different versions: insulation with longitudinal yellow and green stripes and a blue line at the end, or blue insulation with a yellow-green stripe at the joints and at the ends of the conductor.

In three-phase networks, phase A is marked in yellow, phase B in green, phase C in red.

According to the requirements of the current standards, the following letter designation of the conductors is used along with the color coding of the conductors for AC networks:

- in a single-phase network - L;

- in a three-phase network - L with numbers from 1 to 3;

- medium - M;

- neutral, or zero - N;

- grounding - PE;

- combined working and zero - PEN (combination of designations of each of the used conductors).

Models for DC networks are marked with the letter L with a + or - sign, respectively, a positive or negative conductor.

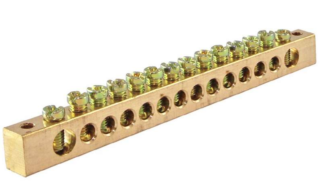

Zero bus

The connection of grounding and neutral working conductors is carried out using a neutral bus. Its construction consists of a conductive core and a plastic base, which is mounted on a DIN rail. The core is made of special electrical copper or brass. The conductive element has holes and clamping bolts. Their presence allows for neat and safe cabling in switchgear assemblies. Models of zero buses are made of different lengths, which allows you to make the required number of mounting holes in the core. Their main area of application is AC or DC networks, designed for operating voltages up to 400V.

Thanks to the use of a zero bus, it will be possible to:

- to increase the efficiency of the used protective automatic devices;

- create several points of connection of loads to the neutral conductor at the same time;

- carefully and safely separate zero and working conductors;

- make visible grounding using a plastic device with a cover to protect the terminals;

- install a single circuit from the grounding point to each load.

An important condition when choosing a zero bus is taking into account the restrictions on the maximum allowable cross-sectional area of wires. This will ensure the safe operation of the network and uninterrupted power supply at the facility. In addition, the selection of the optimal conductor modification is carried out taking into account the maximum number of connected loads.

The installation of the zero bus is carried out directly inside the electrical panel or on a metal rail using a bolted connection. Distinguish between open and closed mounting methods. The first option is provided for electrical cabinets with a closed design, which excludes unauthorized access to the internal contents. Installation in a closed way is optimal for networks to which expensive energy-intensive equipment is connected - machines and mechanisms, power tools, etc.